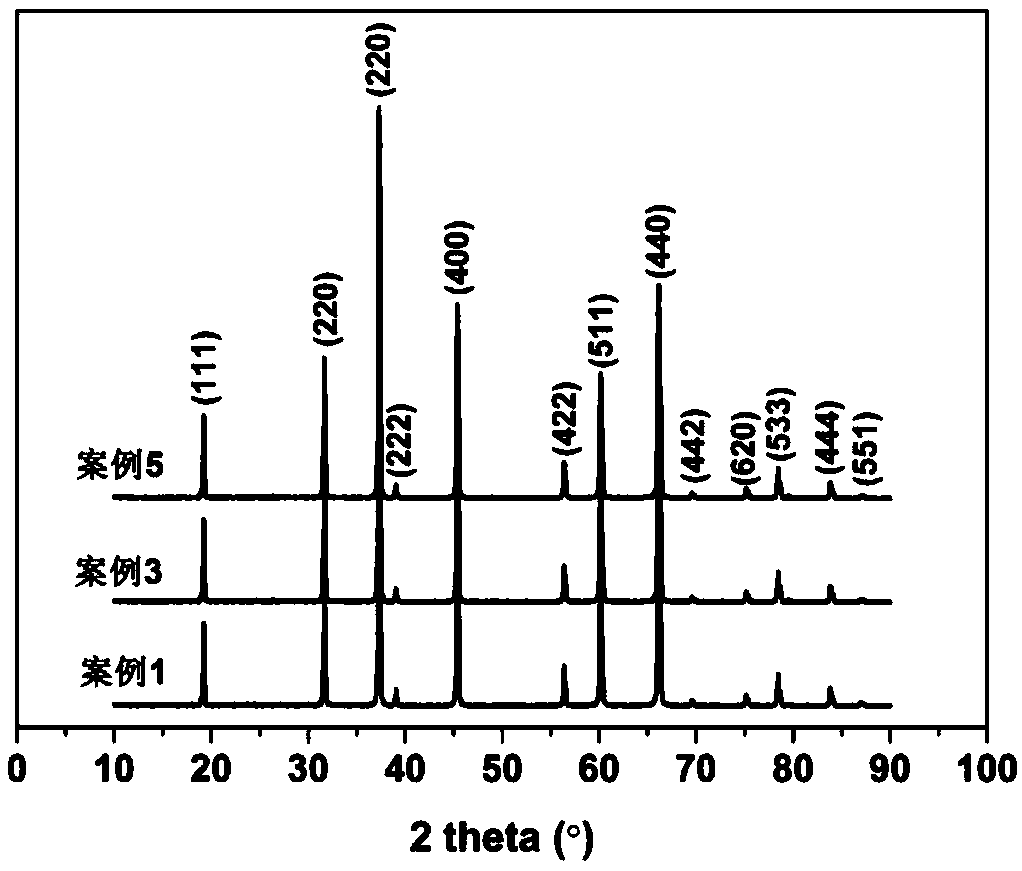

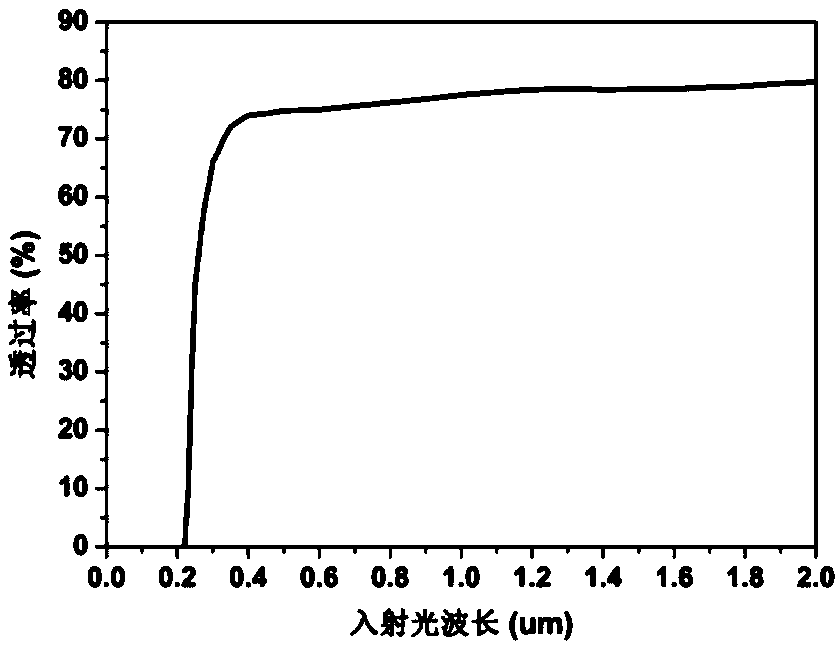

Preparation method of MgAlON transparent ceramic powder

A technology of transparent ceramics and powder, applied in the field of optical materials, can solve the problems of high porosity and difficult to achieve optical transparency, and achieve the effects of low cost, excellent optical transmission performance, and low C content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

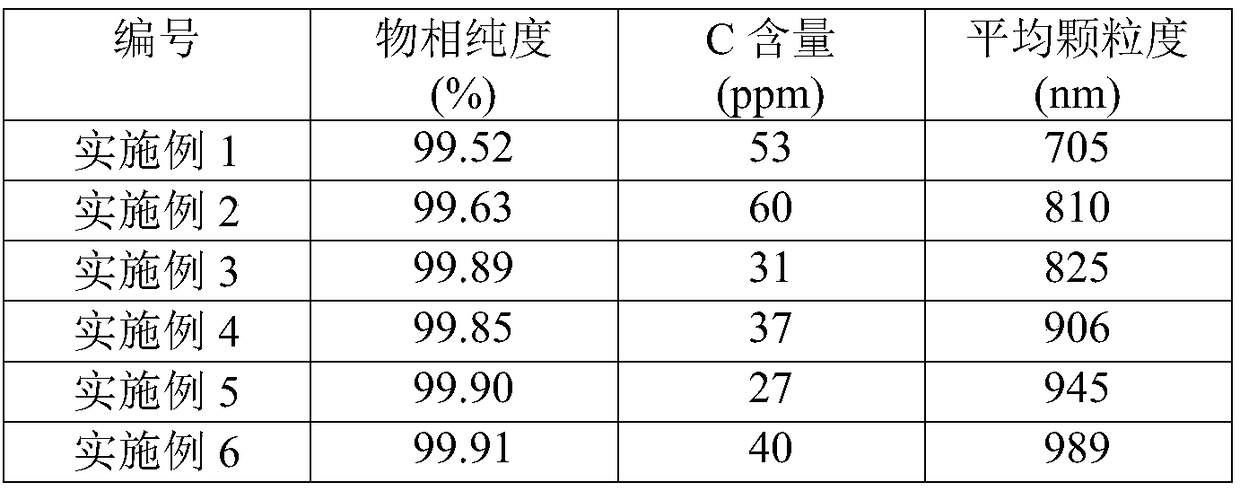

Examples

Embodiment 1

[0027] A preparation method of MgAlON transparent ceramic powder, comprising the following steps:

[0028] (1) Weighing of raw materials: according to a certain proportion, weigh Al powder, γ-Al 2 o 3 Powder and MgO powder, mixed powder, set aside;

[0029] The ratio is: Al powder, γ-Al 2 o 3 The mass fractions of MgO powder and MgO powder are 4wt%, 80wt%, 16wt% respectively;

[0030] The average particle size of the Al powder is 2.5 μm, and the purity is 99.95wt%; γ-Al 2 o 3 Powder average particle size 20nm, purity 99.5wt%; MgO powder average particle size 100nm, purity 99.99wt%;

[0031] (2) Dispersion by ball milling: disperse the mixed powder obtained in step (1) in absolute ethanol, and ball mill for 16 hours to obtain a slurry;

[0032] The rotational speed of the ball mill is 120r / m; the balls used in the ball mill are alumina balls with a purity of 99wt%; the mass ratio of the balls to the mixed powder is 5:1;

Embodiment 2

[0039] A preparation method of MgAlON transparent ceramic powder, comprising the following steps:

[0040] (1) Weighing of raw materials: according to a certain proportion, weigh Al powder, γ-Al 2 o 3 Powder and MgO powder, mixed powder, set aside;

[0041] The ratio is: Al powder, γ-Al 2 o3 The mass fractions of MgO powder and MgO powder are 5wt%, 88wt%, 7wt% respectively;

[0042] The average particle size of the Al powder is 2.5 μm, and the purity is 99.5wt%; γ-Al 2 o 3 Powder average particle size 20nm, purity 99.99wt%; MgO powder average particle size 100nm, purity 99.5wt%;

[0043] (2) Dispersion by ball milling: disperse the mixed powder obtained in step (1) in absolute ethanol, and ball mill for 18 hours to obtain a slurry;

[0044] The rotational speed of the ball mill is 100r / m; the balls used in the ball mill are zirconia balls with a purity of 99wt%; the mass ratio of the balls to the mixed powder is 5:1;

[0045] (3) Slurry drying: take the obtained slurry ...

Embodiment 3

[0051] A preparation method of MgAlON transparent ceramic powder, comprising the following steps:

[0052] (1) Weighing of raw materials: according to a certain proportion, weigh Al powder, γ-Al 2 o 3 Powder and MgO powder, mixed powder, set aside;

[0053] The ratio is: Al powder, γ-Al 2 o 3 The mass fractions of MgO powder and MgO powder are 6wt%, 82wt%, 12wt% respectively;

[0054] The average particle size of the Al powder is 2 μm, and the purity is 99.9 wt %; γ-Al 2 o 3 Powder average particle size 50nm, purity 99.99 wt%; MgO powder average particle size 70nm, purity 99.5 wt%;

[0055] (2) Dispersion by ball milling: disperse the mixed powder obtained in step (1) in absolute ethanol, and ball mill for 20 hours to obtain a slurry;

[0056] The rotational speed of the ball mill is 100r / m; the balls used in the ball mill are alumina balls with a purity of 99.9wt%; the mass ratio of the balls to the mixed powder is 8:1;

[0057] (3) Slurry drying: take the obtained sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com