A kind of comb-shaped structure urethane acrylate and preparation method thereof

The technology of urethane acrylate and isocyanate ethyl acrylate, which is applied in the field of urethane acrylate and its preparation, can solve the problems of unfriendly acrylate reaction process, complicated synthesis method and difficult control of double bond density, etc., and achieves good mutual solubility, The effect of high productivity and high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

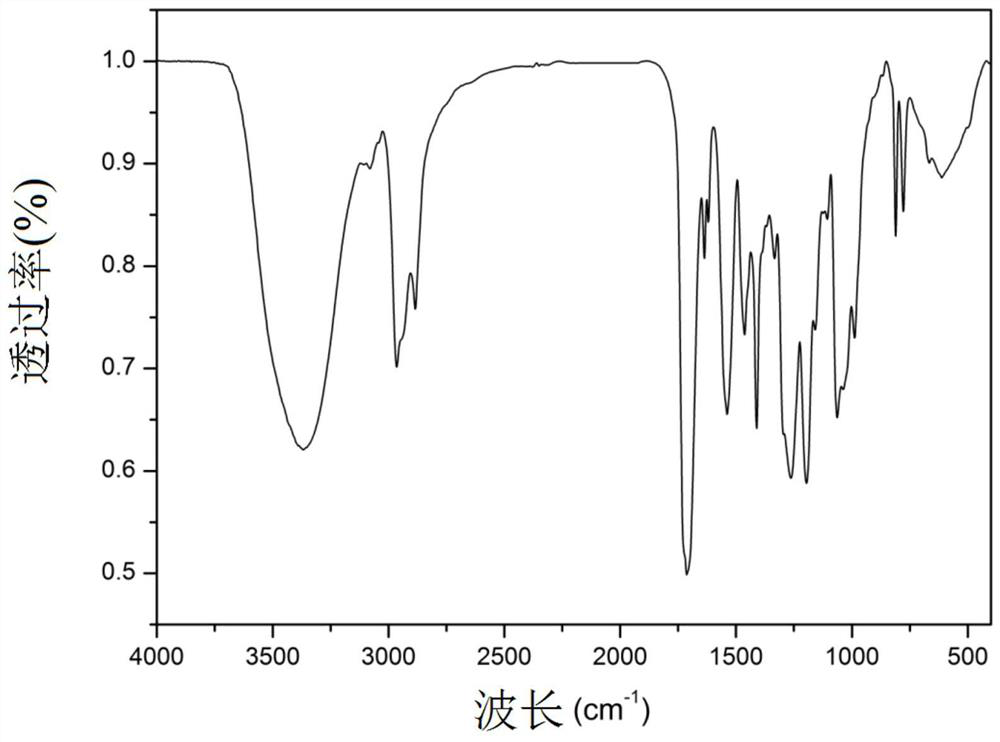

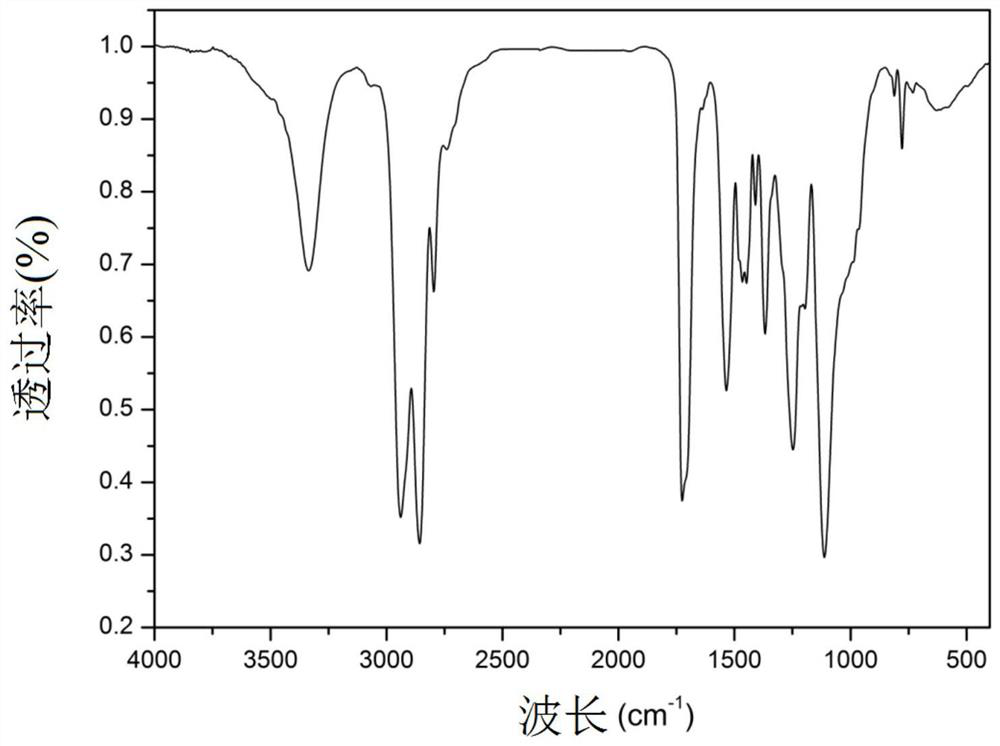

Image

Examples

specific Embodiment approach 1

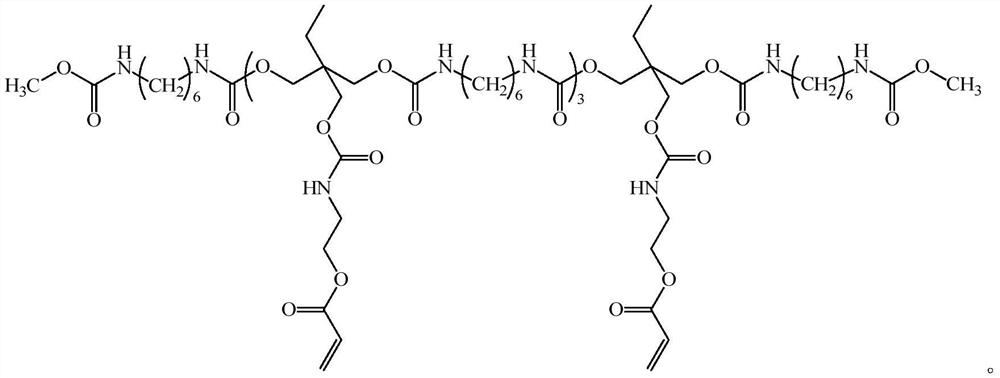

[0025] Specific implementation mode 1: This implementation mode is a structure of comb-shaped structure polyurethane acrylate:

[0026] Wherein, the R is The R 1 for -CH 3 , The value range of m is 1-9.

specific Embodiment approach 2

[0027] Specific embodiment two: this embodiment is a method for preparing polyurethane acrylate with a comb structure, which is completed in the following steps:

[0028] 1. Synthesis of a comb-shaped polyurethane acrylate prepolymer with isocyanate groups at both ends:

[0029] Mix dihydroxy acrylate and diisocyanate evenly under a nitrogen atmosphere, then heat up to 40°C-60°C, and then react for 3h-5h in a nitrogen atmosphere at a temperature of 40°C-60°C to obtain isocyanate groups at both ends. Comb structure polyurethane acrylate prepolymer;

[0030] The molar ratio of dihydroxyacrylate and diisocyanate described in step 1 is 1:(1.1~1.5);

[0031] 2. Mix the comb-shaped polyurethane acrylate prepolymer with isocyanate groups at both ends and monohydric alcohol evenly, then raise the temperature to 50°C-80°C, and then react at a temperature of 50°C-80°C for 2h-4h to obtain Comb structure polyurethane acrylate;

[0032] The molar ratio of the comb structure urethane acr...

specific Embodiment approach 3

[0042] Embodiment 3: The difference between this embodiment and Embodiment 2 is that the diisocyanate is one of TDI, MDI, IPDI, HDI, HMDI and HTDI or a mixture of several of them. Other steps are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com