A preparation process for packaging and packaging prepared by the process

A technology of preparation process and raw materials, applied in the field of preparation process and packaging prepared by this process, can solve problems such as broken, worn items, unpackable, etc., and achieve the effects of improving weather resistance, realizing repeated use, and controlling foaming ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Hereinafter, when explaining the embodiments of the present invention, detailed descriptions of related known elements or functions will be omitted if they interfere with the gist of the present invention.

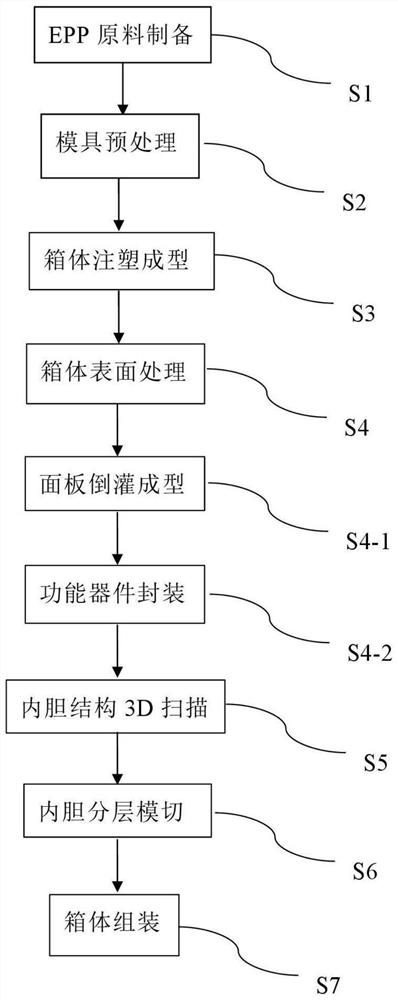

[0037] refer to figure 1 , the invention provides a preparation process for packaging, comprising the steps of:

[0038] S1. Preparation of expanded polypropylene (EPP) raw materials:

[0039] Using polypropylene (PP) powder as raw material, PP, nano-SiO 2 , lubricant, and nucleating agent are mixed in a high-speed mixer at a mass ratio of 1000:1:1:0.5, then added to a high-pressure reactor and heated to soften, and high-pressure carbon dioxide gas is introduced as a foaming agent and kept foaming. The bubble pressure is in the range of 1.5-3.0MPa, and the foaming temperature is kept in the range of 135-150°C. After the high-pressure carbon dioxide gas diffuses into the PP, nano-SiO 2 After the mixed resin particles composed of lubricant, nucleating agent form a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com