Preparation method of bilateral polyether modified amino silicon oil

A modification technology of amino silicone oil and polyether, which is applied in the chemical industry, can solve the problems of anti-yellowing, hydrophilic emulsion stability and poor adsorption, and achieve high controllability and hydrophilicity of ammonia value and hydrophilicity. Good water resistance and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

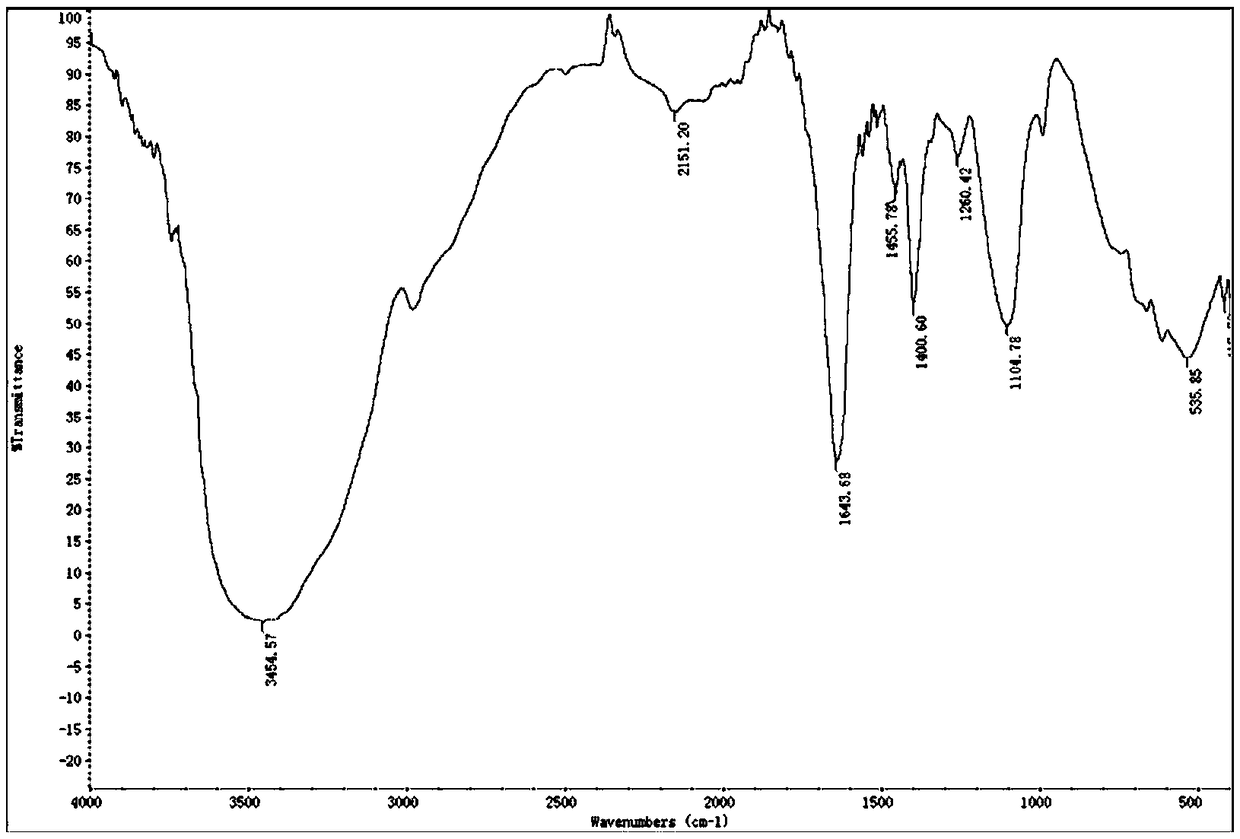

Image

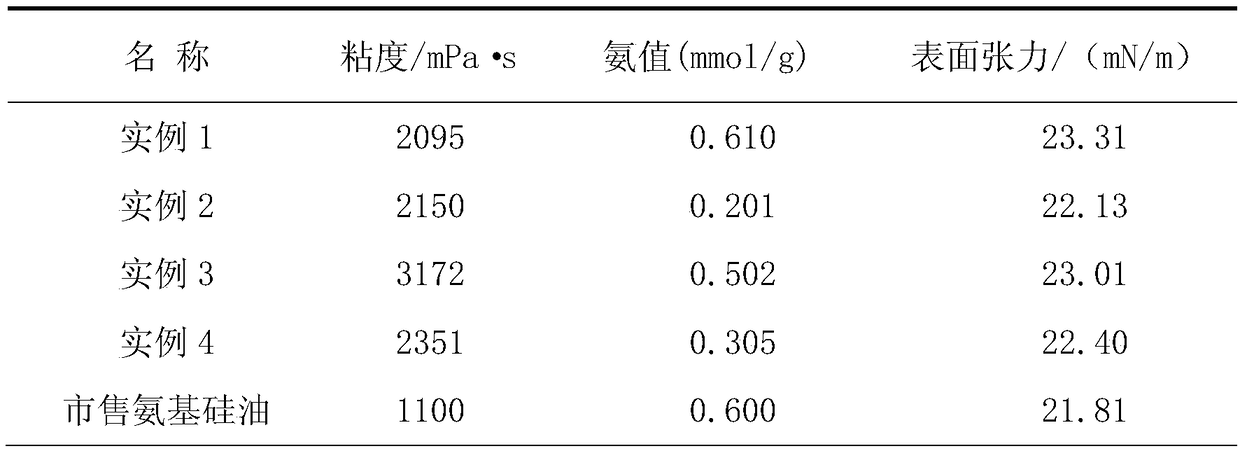

Examples

Embodiment 1

[0029] a. Preparation of amino hydrogen silicone oil

[0030] Mix 20 parts of KH602 and 18 parts of water in a closed four-necked flask and stir at a constant speed for hydrolysis, the hydrolysis temperature is 10°C, and the hydrolysis time is 2 hours; then maintain at -0.09MPa for 1 hour to remove low-molecular compounds; the viscosity obtained after standing still is 300mPa·s (25°C) KH602 hydrolyzate mainly composed of silicon glycol.

[0031] 71.9 parts of octamethylcyclotetrasiloxane (D 4 ) mixed with 20 parts of high hydrogen-containing silicone oil with a hydrogen content of 1.48%, and dehydrated at 65°C and -0.1MPa for 1h; KH602 hydrolyzate mixed, under high-purity nitrogen atmosphere, add 2 parts of sulfuric acid solution with a concentration of 98% by mass, add 2 parts of end-capping agent hexamethyldisiloxane (MM) after the viscosity of the system increases, and keep at 65°C React for 4 hours; cool down to below 50°C, add 4 parts of sodium bicarbonate powder to neu...

Embodiment 2

[0038] a. Preparation of amino hydrogen silicone oil

[0039] Mix 20 parts of KH602 and 18 parts of water in a closed four-necked flask and stir at a constant speed for hydrolysis, the hydrolysis temperature is 10°C, and the hydrolysis time is 2 hours; then maintain at -0.09MPa for 1 hour to remove low-molecular compounds; the viscosity obtained after standing still is 300mPa·s (25°C) KH602 hydrolyzate mainly composed of silicon glycol.

[0040] 87 parts of octamethylcyclotetrasiloxane (D 4 ) mixed with 9 parts of high hydrogen-containing silicone oil with a hydrogen content of 1.48%, and dehydrated at 65°C and -0.1MPa for 1h; KH602 hydrolyzate mixed, under high-purity nitrogen atmosphere, adding 2 parts of concentrated sulfuric acid with a mass percentage concentration of 98%, adding 2 parts of end-capping agent hexamethyldisiloxane (MM) after the system viscosity increased, keeping 65 ℃ for 4 hours; cool down to below 50℃, add 4 parts of sodium bicarbonate powder to neutra...

Embodiment 3

[0045] a. Preparation of amino hydrogen silicone oil

[0046] Mix 20 parts of KH602 and 18 parts of water in a closed four-necked flask and stir at a constant speed for hydrolysis, the hydrolysis temperature is 10°C, and the hydrolysis time is 2 hours; then maintain at -0.09MPa for 1 hour to remove low-molecular compounds; the viscosity obtained after standing still is 300mPa·s (25°C) KH602 hydrolyzate mainly composed of silicon glycol.

[0047] 78 parts of octamethylcyclotetrasiloxane (D 4 ) mixed with 15 parts of high hydrogen-containing silicone oil with a hydrogen content of 1.48%, and dehydrated at 65°C and -0.1MPa for 1 hour; KH602 hydrolyzate mixed, under high-purity nitrogen atmosphere, adding 2 parts of concentrated sulfuric acid with a mass percentage concentration of 98%, adding 2 parts of end-capping agent hexamethyldisiloxane (MM) after the system viscosity increased, keeping 65 ℃ for 4 hours; cool down to below 50℃, add 4 parts of sodium bicarbonate powder to n...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap