Terpolymer-reinforced polypropylene

A terpolymer, polypropylene technology, applied in the field of automobile decoration, can solve the problems of restricting the application of polypropylene, poor scratch resistance, low surface hardness, etc., and achieve high toughness, good scratch resistance, and good dimensional stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

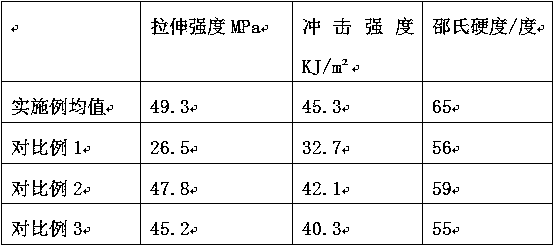

Examples

Embodiment 1

[0018] A ternary copolymer reinforced polypropylene, which is made of the following components in parts by weight: polypropylene resin 92, talc powder 4, nano graphene 2, nano zeolite powder 6, terpolymer 8, color masterbatch 1.2, Stearyl 0.3, sodium dihydrogen phosphate 1.8, magnesium hydroxide 1.2, 1,1-bis-(tert-butylperoxy)cyclohexane 0.5, plasticizer 1.1.

[0019] Further, the talc powder is pretreated: after talc powder and the aluminate coupling agent solution with a mass fraction of 6.5% are uniformly mixed at a ratio of 180g:300mL, the talc powder is sequentially mixed at 1200r / min and 2000r / min respectively. Grind for 30 minutes, then filter, rinse with deionized water to neutrality, and dry to constant weight.

[0020] Further, the nano zeolite powder is pretreated: talc powder and 3.8% organosilane coupling agent solution are mixed uniformly at a ratio of 150g:250mL, and then performed at 1500r / min and 2500r / min respectively. Grind for 45 minutes, then filter, rinse wit...

Embodiment 2

[0030] A ternary copolymer reinforced polypropylene, which is made of the following components in parts by weight: polypropylene resin 95, talc powder 6, nano graphene 4, nano zeolite powder 8, terpolymer 12, color masterbatch 1.5, Stearoyl 0.6, sodium dihydrogen phosphate 2.2, magnesium hydroxide 1.7, 1,1-bis-(tert-butylperoxy)cyclohexane 0.9, plasticizer 1.5.

[0031] Further, the talc powder is pretreated: after talc powder and the aluminate coupling agent solution with a mass fraction of 6.5% are uniformly mixed at a ratio of 180g:300mL, the talc powder is sequentially mixed at 1200r / min and 2000r / min respectively. Grind for 30 minutes, then filter, rinse with deionized water to neutrality, and dry to constant weight.

[0032] Further, the nano zeolite powder is pretreated: talc powder and 3.8% organosilane coupling agent solution are mixed uniformly at a ratio of 150g:250mL, and then performed at 1500r / min and 2500r / min respectively. Grind for 45 minutes, then filter, rinse w...

Embodiment 3

[0042] A kind of terpolymer reinforced polypropylene, which is made of the following components by weight: polypropylene resin 93, talc powder 5, nano graphene 3, nano zeolite powder 7, terpolymer 10, masterbatch 1.3, Stearyl 0.5, sodium dihydrogen phosphate 2.1, magnesium hydroxide 1.6, 1,1-bis-(tert-butylperoxy)cyclohexane 0.8, plasticizer 1.3.

[0043] Further, the talc powder is pretreated: after talc powder and the aluminate coupling agent solution with a mass fraction of 6.5% are uniformly mixed at a ratio of 180g:300mL, the talc powder is sequentially mixed at 1200r / min and 2000r / min respectively. Grind for 30 minutes, then filter, rinse with deionized water to neutrality, and dry to constant weight.

[0044] Further, the nano zeolite powder is pretreated: talc powder and 3.8% organosilane coupling agent solution are mixed uniformly at a ratio of 150g:250mL, and then performed at 1500r / min and 2500r / min respectively. Grind for 45 minutes, then filter, rinse with deionized w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com