Surface modified magnesium hydroxide as well as preparation method and application thereof

A magnesium hydroxide, surface modification technology, applied in the direction of dyeing low-molecular-weight organic compounds, fibrous fillers, etc., can solve the problems of compatibility, thermal stability and poor processing fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

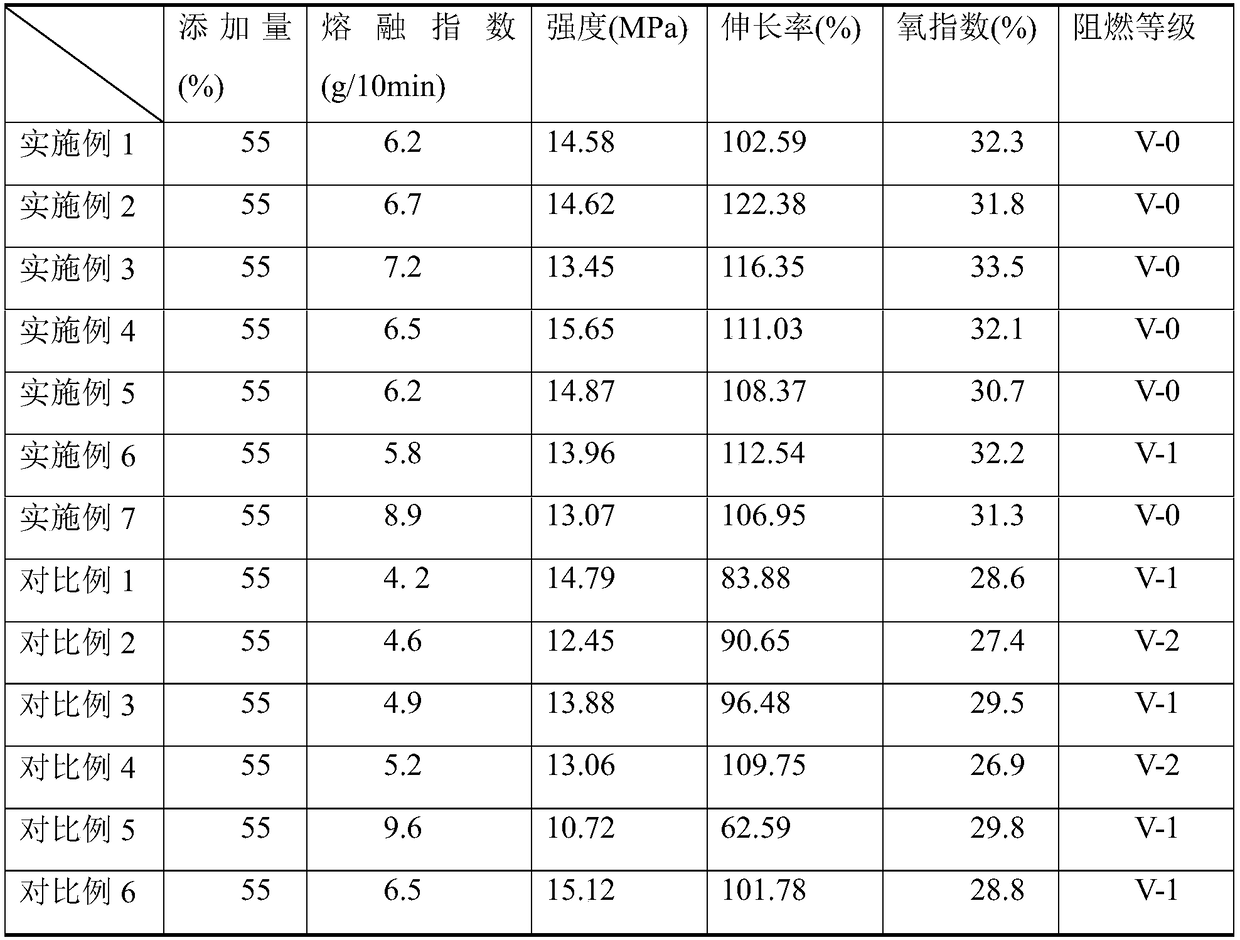

Examples

preparation example Construction

[0019] The first aspect of the present invention provides a method for preparing surface-modified magnesium hydroxide, wherein the method includes the following steps:

[0020] (1) First contact the modifier I with magnesium hydroxide;

[0021] (2) Perform a second contact between the modifier II and the product obtained in step (1);

[0022] Wherein, the modifier I is castor oil;

[0023] Wherein, the modifier II is phosphate or organic hypophosphorous acid metal salt.

[0024] According to the present invention, the main components of castor oil are cis-ricinoleic acid, palmitic acid, stearic acid, linoleic acid, linolenic acid and dihydroxystearic acid. The inventors of the present invention have discovered through a large number of scientific experiments that castor oil can It reacts with the strong polar hydroxyl groups on the surface of magnesium hydroxide, and coats the surface of magnesium hydroxide to improve its compatibility with polymers.

[0025] According to the present in...

Embodiment 1

[0043] This example is to illustrate the surface modified magnesium hydroxide prepared by the preparation method of the present invention.

[0044] (1) Using magnesium hydroxide with a particle size of 5000 mesh as raw material, disperse at high speed in a mixer at a stirring rate of 3500r / min. After the temperature rises to 60°C, slowly add castor at a dropping rate of 1ml / min Stir the sesame oil for 30 minutes;

[0045] (2) Then add triethyl phosphate modified coated magnesium hydroxide, and continue to stir for 60 minutes at a temperature of 60°C to obtain modified magnesium hydroxide;

[0046] Among them, the amount of castor oil is 1% by weight of the magnesium hydroxide, and the amount of triethyl phosphate is 3% by weight of the magnesium hydroxide.

[0047] The result is a white powdery surface-modified magnesium hydroxide, and

[0048] In the processing of polymer composite materials with PE and EVA as matrix resins, the surface-modified magnesium hydroxide is used as a flame ...

Embodiment 2

[0050] This example is to illustrate the surface modified magnesium hydroxide prepared by the preparation method of the present invention.

[0051] (1) Using magnesium hydroxide with a particle size of 5000 mesh as raw material, disperse at a high speed in a mixer at a stirring rate of 2000r / min. After the temperature rises to 70°C, add slowly at a dropping rate of 0.5ml / min Stir the castor oil for 50 minutes;

[0052] (2) Then add triethyl phosphate modified coated magnesium hydroxide, and continue to stir for 30 minutes at a temperature of 70°C to obtain modified magnesium hydroxide;

[0053] Among them, the amount of castor oil is 1.5% by weight of the magnesium hydroxide, and the amount of triethyl phosphate is 5% by weight of the magnesium hydroxide.

[0054] The result is a white powdery surface-modified magnesium hydroxide, and

[0055] In the processing of polymer composites with PE and EVA as matrix resins, the surface-modified magnesium hydroxide is used as a flame retardant....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com