Negative-pressure fuel coal coupled biomass gasification power generation system and electrical energy conversion method

A power generation system, biomass technology, applied in gasification process, manufacture of combustible gas, petroleum industry, etc., can solve problems such as tar staining on the inner wall and heating surface of the transportation pipeline, unstable feeding system, and flue gas backflow, etc., to achieve The feeding system is simple and reliable, avoiding tar precipitation and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

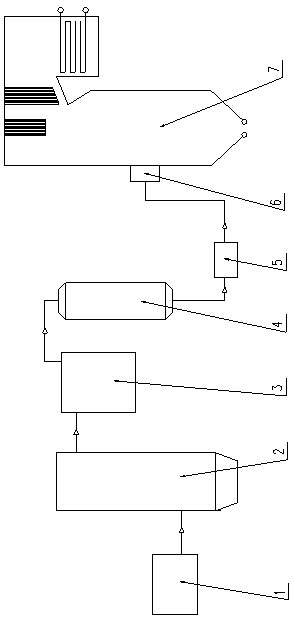

[0018] A negative pressure coal-fired coupled biomass gasification power generation system, which consists of: a feeding device 1, the feeding device is connected to the gasifier system 2 through pipelines, and the gasifier system is connected to the ash and slag The processing device 3 is connected through a pipeline, the ash processing device is connected with the gas cooling device 4 through a pipeline, the gas cooling device is connected with the gas delivery device 5 through a pipeline, and the gas delivery device It is connected to a gas burning device 6 through a pipeline, and the gas burning device is connected to a coal-fired boiler 7 . .

Embodiment 2

[0020] According to the negative pressure coal-fired coupled biomass gasification power generation system described in Example 1, an induced draft fan is installed in the gas delivery device, and the gasifier system runs under negative pressure in the section before the induced draft fan, The section from the induced draft fan to the gas combustion system runs under positive pressure. The gasification furnace system and the gas delivery device are equipped with inert gas purge points and release points. The gas delivery device The gas flow rate is 15~30m / s.

Embodiment 3

[0022] According to the negative pressure coal-fired coupling biomass gasification power generation system described in Example 1, the gas cooling device adopts the indirect heat exchange mode of gas-heat transfer oil-cooling water, and the gas-heat conduction in the gas cooling device The design temperature of the outer wall of the oil heat exchanger is 350-450°C, and the cooling water in the gas cooling device is taken from and sent back to the auxiliary system of the coal-fired boiler.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com