Lubricating grease composition for motor bearing of high-speed dust collector and preparation method

A grease composition and a technology for motor bearings, applied in the field of grease, can solve problems such as service life to be explored, and achieve the effects of ensuring service life, improving low-noise performance, and long lubricating cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

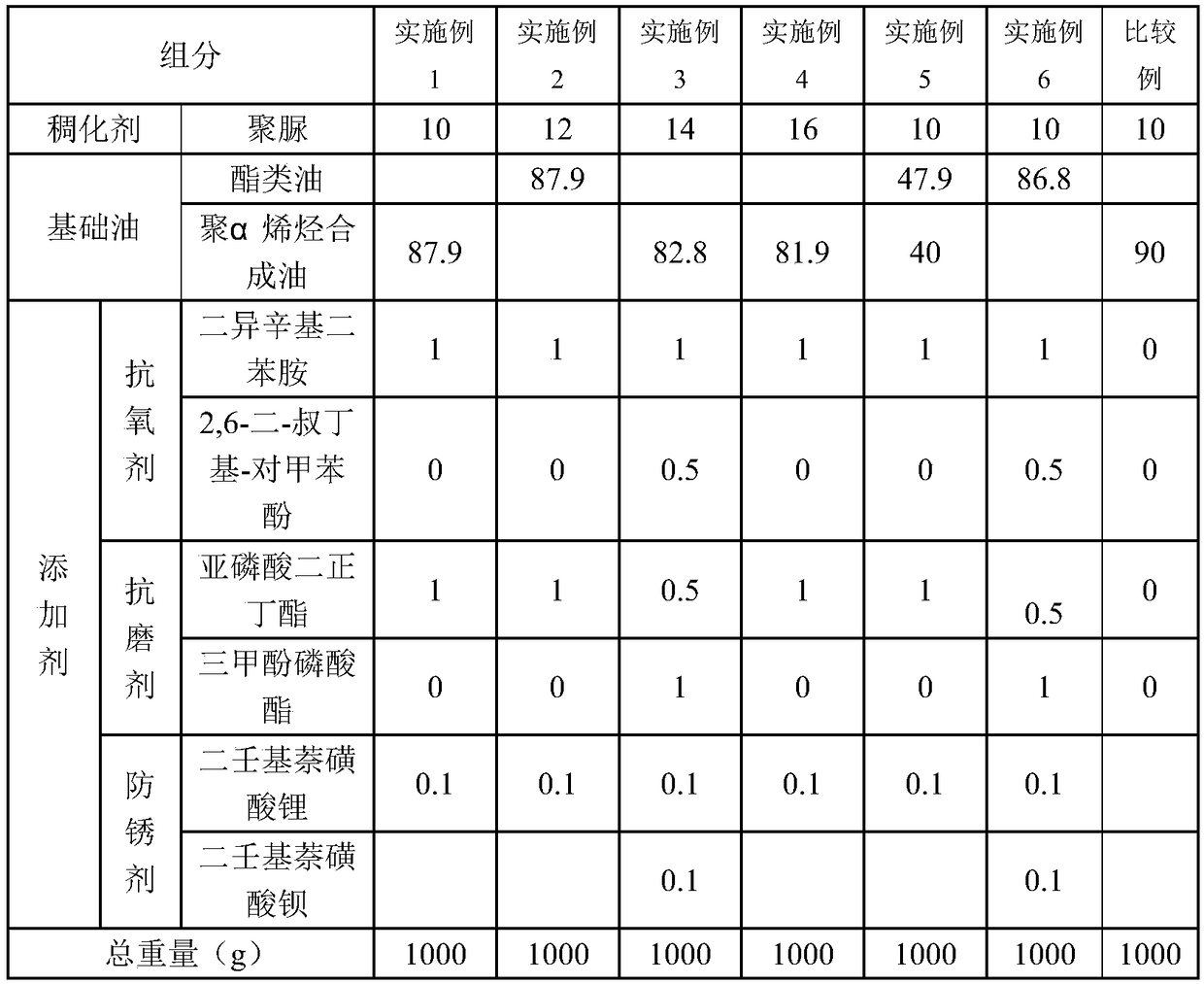

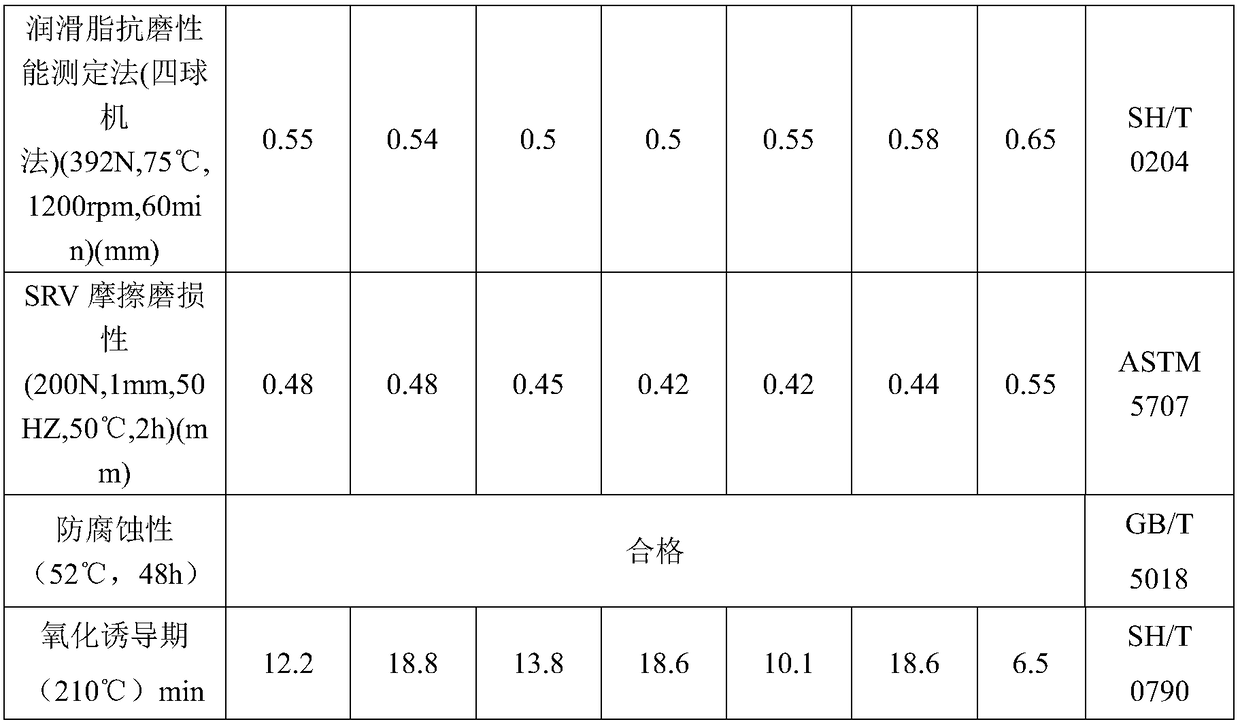

Examples

Embodiment 1

[0034] Example 1 Add 40 g of diisocyanate in the thickener to 439.5 g of base oil, the base oil is polyalphaolefin synthetic oil, and 60 g of organic amine is added to another part of 439.5 g of base oil, and the temperature of the two reactors is raised to 60°C, keep the temperature for 10 minutes, put the two tanks of materials into the reactor, stir and heat to 66°C, react for 1h±5min, slowly raise the temperature to the highest refining temperature of 180°C to form a dipolyurea thickener with interlaced tubular fiber structure, control the temperature rise The time is between 1.5h and 2h. When the temperature rises to 160°C-170°C, add 10g of antioxidant aromatic amine alkylated diphenylamine; after the material naturally cools down to below 80°C, add 10g of antiwear agent diphosphite For n-butyl ester, add 1g of lithium dinonylnaphthalenesulfonate as an anti-rust agent, stir evenly, and carry out post-treatment, after cooling to room temperature, detect the noise level of t...

Embodiment 2

[0035] Example 2 Add 48g of diisocyanate in the thickener to 439.5g of base oil, the base oil is ester oil, add 72g of organic amine to another part of 439.5g of base oil, and raise the temperature of the two reactors to 60°C After 10 minutes of constant temperature, put the two cans of materials into the reactor, stir and heat to 66°C, react for 1h±5min, slowly raise the temperature to the highest refining temperature of 180°C to form a dipolyurea thickener without fiber crystal structure, control the heating time at Between 1.5h and 2h, when the temperature rises to 160°C-170°C, add 10g of antioxidant aromatic amine alkylated diphenylamine; after the material naturally cools down to below 80°C, add 10g of anti-wear agent di-n-butyl phosphite Add 1g of lithium dinonylnaphthalene sulfonate as an antirust agent, stir evenly, and carry out post-processing. After cooling to room temperature, the noise level of the product is tested, and the finished product is packed in cans.

Embodiment 3

[0036] Example 3 Add 56g of diisocyanate in the thickener to 414g of base oil, the base oil is polyalphaolefin synthetic oil, add 84g of organic amine to another part of 414g of base oil, and raise the temperature of the two reactors to 60°C After 10 minutes of constant temperature, put the two cans of materials into the reactor, stir and heat to 66°C, react for 1h±5min, slowly raise the temperature to the highest refining temperature of 180°C to form a dipolyurea thickener without fiber crystal structure, control the heating time at Between 1.5h and 2h, when the temperature rises to 160°C-170°C, add 10g of antioxidant aromatic amine alkylated diphenylamine and 5g of 2,6-di-tert-butyl-p-cresol; wait for the material to cool down naturally After the temperature is below 80°C, add 5g of di-n-butyl phosphite and 10g of tricresyl phosphate as anti-wear agent; add 1g of lithium dinonylnaphthalenesulfonate and 1g of barium dinonylnaphthalenesulfonate as anti-rust agent, stir evenly a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com