Environment-friendly antirust oil with no sulfonate

An environmentally friendly, anti-rust oil technology, applied in the petroleum industry, lubricating compositions, etc., to achieve the effect of convenient use, easy preparation, and dense film formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

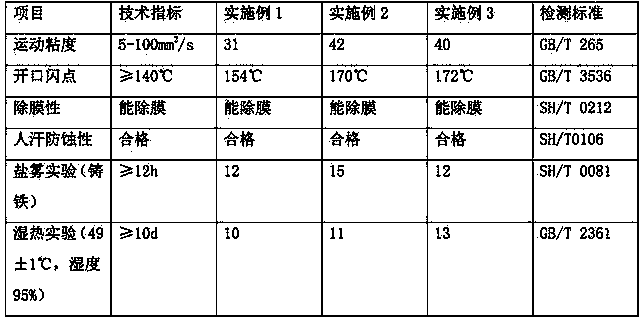

Examples

Embodiment 1

[0017] An environment-friendly anti-rust oil without sulfonates, comprising the following components in parts by weight:

[0018] Fischer-Tropsch synthetic oil: 80%

[0019] Diethanolamide dodecenylsuccinate: 13%

[0020] Tetrahydrobenzotriazole: 2%

[0021] Dioctyl phthalate: 5%.

[0022] Preparation process: Add 80 parts of Fischer-Tropsch synthetic oil into the reactor, heat to 50°C, and add 13 parts of dodecenylsuccinic acid diethanolamide, 2 parts of tetrahydrobenzotriazole and 5 parts of Parts of dioctyl phthalate, stirred at constant temperature for 30min.

[0023] Example of use: Soak the cast iron workpiece in the anti-rust oil for 3 minutes, and let it dry at room temperature.

Embodiment 2

[0025] An environment-friendly anti-rust oil without sulfonates, comprising the following components in parts by weight:

[0026] Fischer-Tropsch synthetic oil: 80%

[0027] Tall oleic acid diethanolamide: 10%

[0028] Benzotriazole: 5%

[0029] Diethylene glycol propyl ether: 5%.

[0030] Preparation process: Add 80 parts of Fischer-Tropsch synthetic oil into the reactor, heat to 50°C, and add 10 parts of tall oleic acid diethanolamide, 5 parts of benzotriazole and 5 parts of diethyl Glycol propyl ether, stirred at constant temperature for 30min.

[0031] Example of use: Soak the cast iron workpiece in the anti-rust oil for 3 minutes, and let it dry at room temperature.

Embodiment 3

[0033] An environment-friendly anti-rust oil without sulfonates, comprising the following components in parts by weight:

[0034] Fischer-Tropsch synthetic oil: 85%

[0035] Diethanolamide dodecenylsuccinate: 6%

[0036] Diethanolamide Laurate: 3%

[0037] Benzotriazole: 2%

[0038] Dibutyl phthalate: 4%.

[0039] Preparation process: Add 85 parts of Fischer-Tropsch synthetic oil into the reactor, heat to 50°C, and add 6 parts of dodecenylsuccinic acid diethanolamide, 3 parts of lauric acid diethanolamide, 2 parts of 1 part of benzotriazole and 4 parts of dibutyl phthalate, stirred at constant temperature for 30 minutes.

[0040] Example of use: Soak the cast iron workpiece in the anti-rust oil for 3 minutes, and let it dry at room temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com