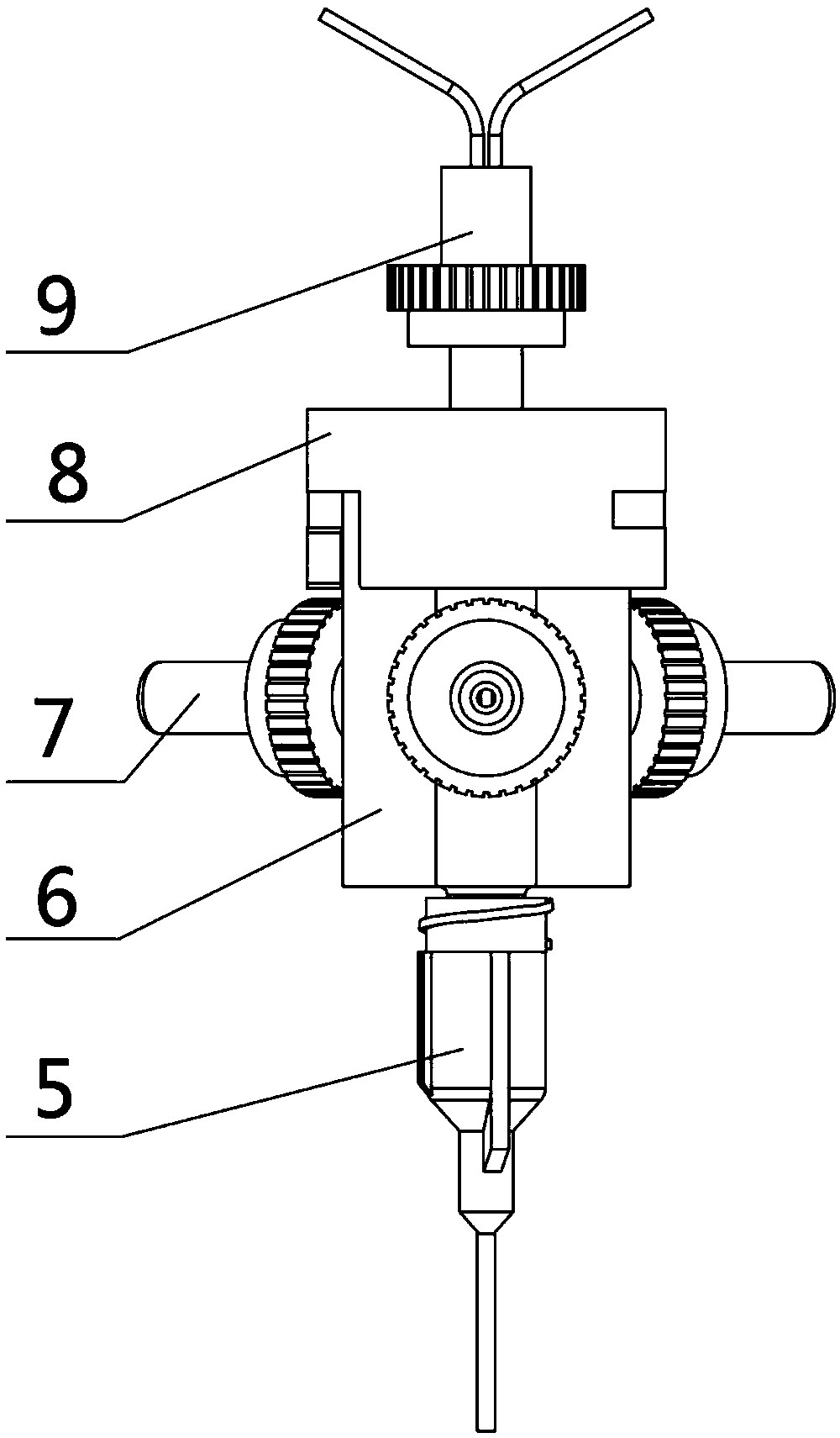

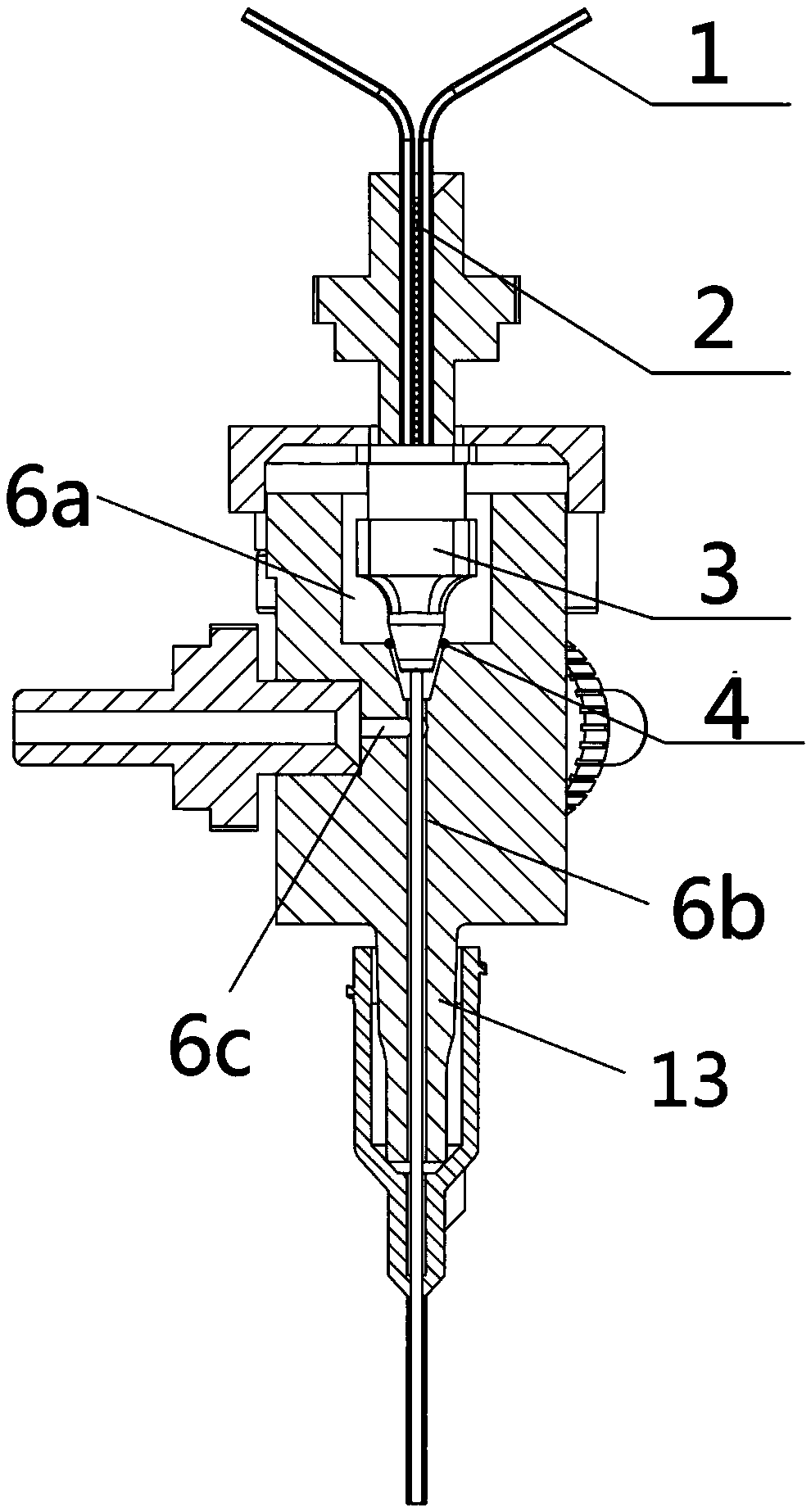

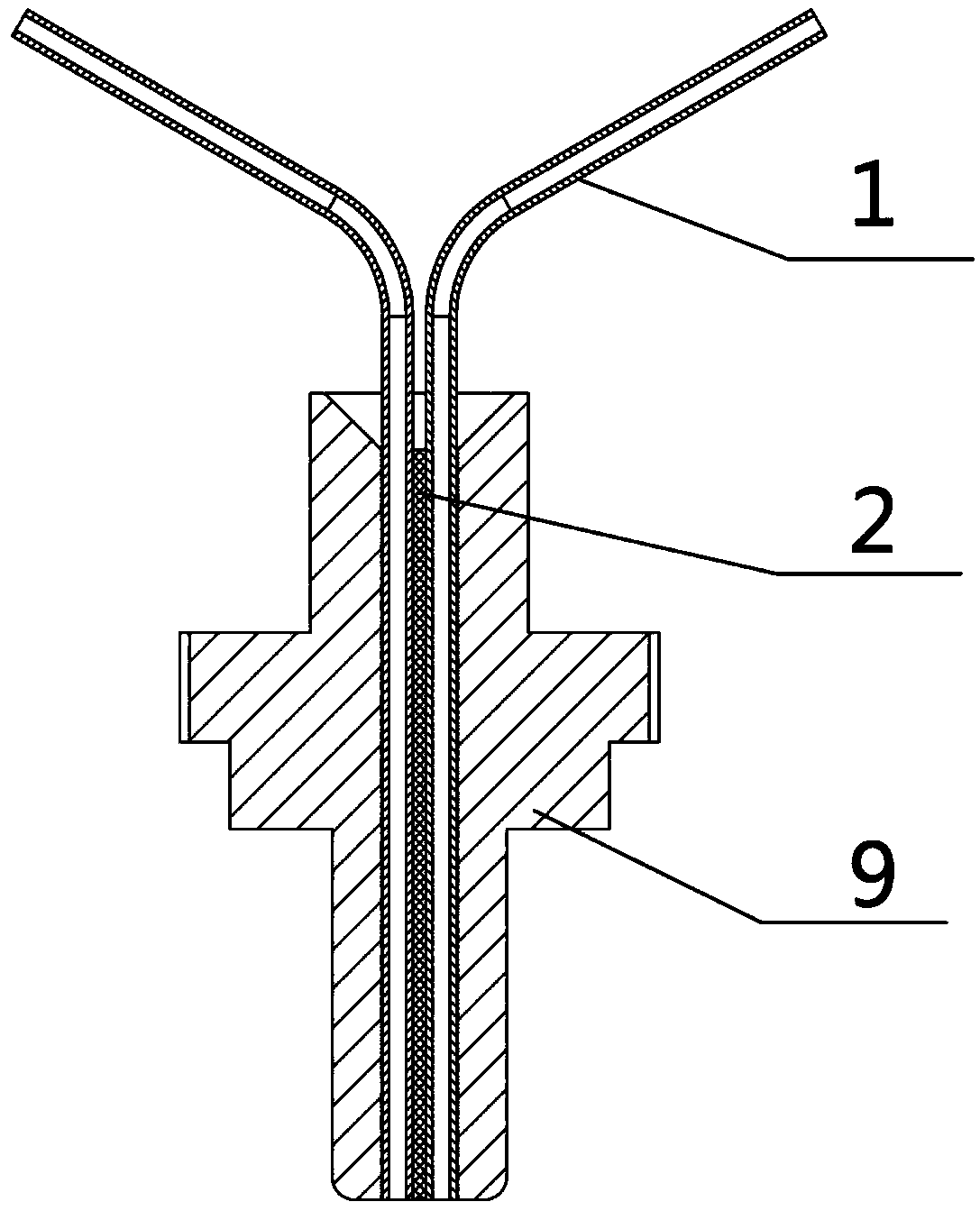

Multi-component coaxial printing sprayer

A printing nozzle and multi-component technology, which is applied in the field of 3D printing, can solve the problems affecting the position accuracy of micro-droplet injection, not using multi-component injection control, and the coaxiality of the nozzle cannot be guaranteed, etc., to achieve simple design, The effect of simple structure and low manufacturing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example

[0072] Gel microspheres containing different cell ratios (human umbilical cord vascular endothelial cells and human bone marrow mesenchymal stem cells) are produced in large quantities with the multi-component coaxial printing nozzle of the present invention, and the effect of the difference of the two cell ratios on the growth of vascular endothelial cells is studied. Effects of vascularization characterization and calcification of bone marrow mesenchymal stem cells.

[0073]Step 1. Prepare all parts, soak the top cover, positioning seat, multi-component positioning components, Luer connector, silicone sealing ring, inner nozzle, and outer nozzle in 75% medical alcohol in advance, seal and wrap it with a container, and place it Treat in an ultrasonic cleaning machine for more than 10 minutes to remove foreign matter such as surface oxide layer and oil layer. Then take it out and place it on a clean bench, wash it three times with deionized water, and dry it in the air. For t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com