Energy-saving and environment-friendly fuel gas burner

An energy-saving and environmental-friendly, gas-fired burner technology, which is applied to gas-fuel burners, burners, combustion methods, etc., can solve the problem that the burner cannot be fixed, the air volume of the air supply system cannot be flexibly adjusted, and the environmental protection and energy-saving of the gas burner cannot be realized. and other problems to achieve the effect of saving gas and avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

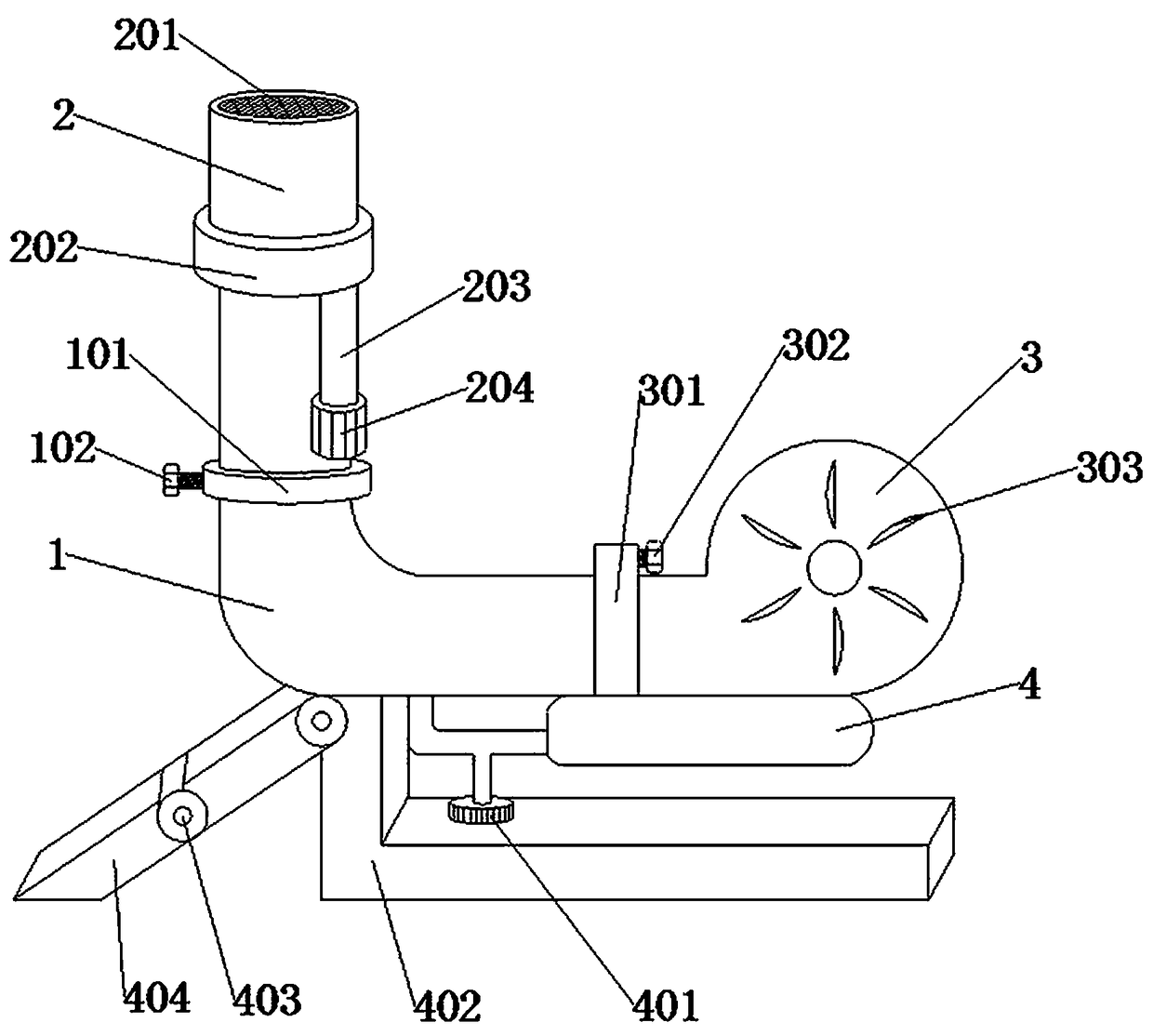

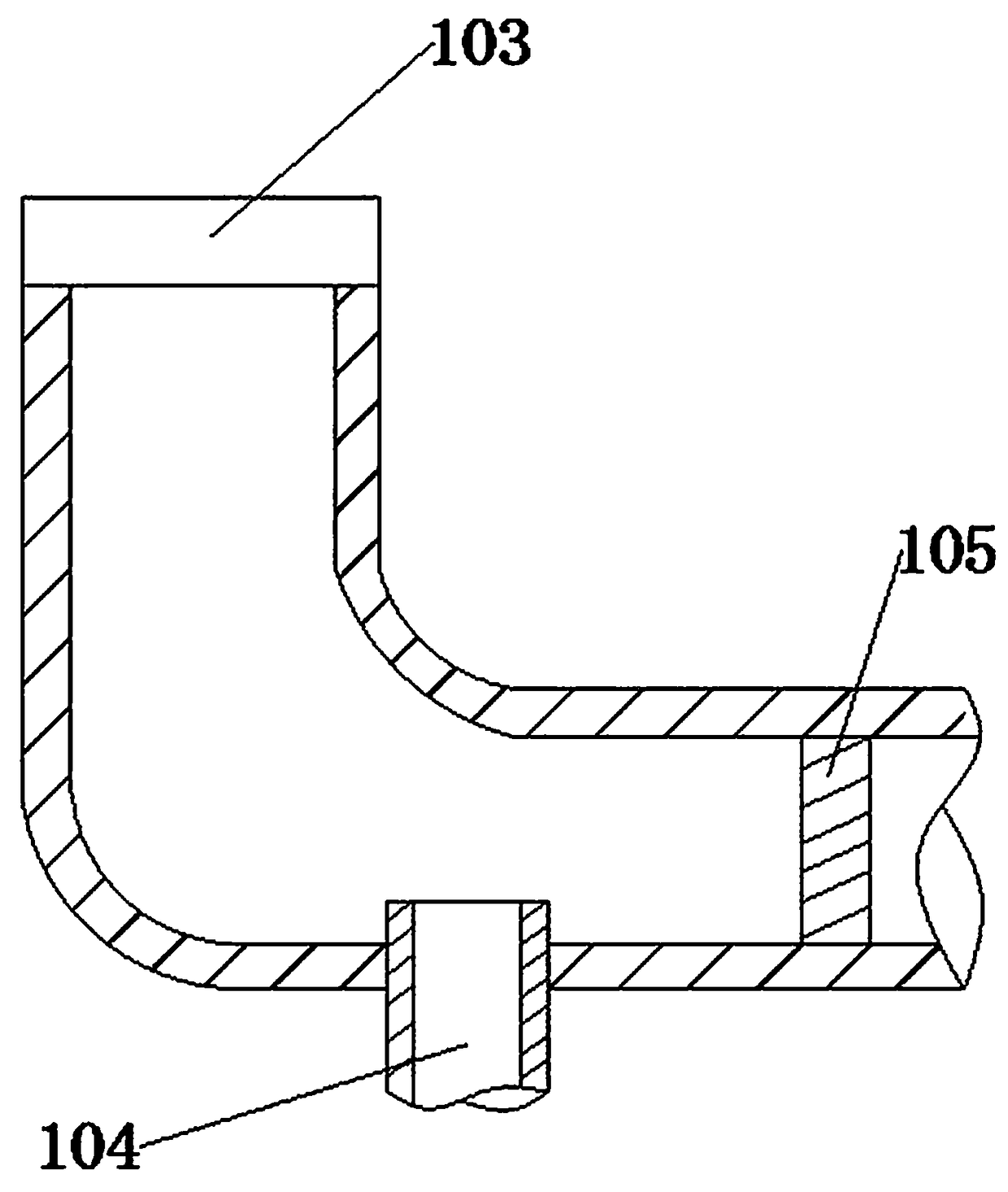

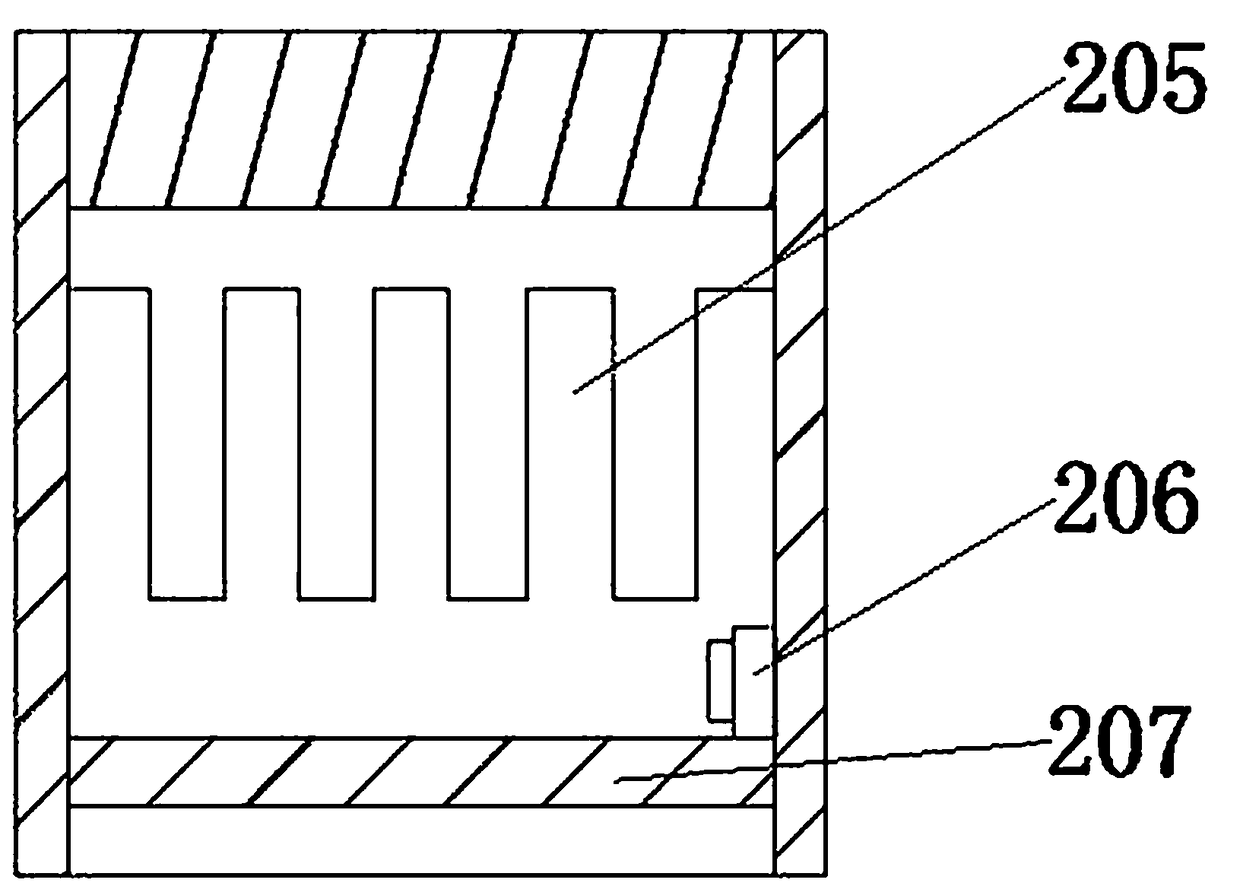

[0027] see Figure 1-4 , the present invention provides a technical solution: an energy-saving and environmentally friendly gas burner, comprising a gas mixing chamber 1, a combustion chamber 2 and a blower 3, an adjustment ring 101 is sleeved above the gas mixing chamber 1, and the adjustment ring 101 can be along the gas The mixing chamber 1 rotates in the axial direction to realize flexible adjustment. The upper part of the adjustment ring 101 is connected with the combustion chamber 2, and the combustion chamber 2 is in the shape of a "cylinder", which is more stable. The outer wall of the combustion chamber 2 is sleeved with a cleaning swivel 202 , an ignition tube 203 is connected through the inside of the cleaning swivel 202, and the ignition tube 203 is a high-temperature resistant insulating material to ensure the safety of the device. An ignition control button 204 is sleeved at the end of the ignition tube 203 away from the cleaning swivel 202, and the gas is mixed. ...

Embodiment 2

[0029]In an embodiment, an energy-saving and environment-friendly gas burner includes a gas mixing chamber 1, a combustion chamber 2, and a blower 3. An adjusting ring 101 is sleeved above the gas mixing chamber 1, and the adjusting ring 101 can move along the axis of the gas mixing chamber 1. Rotate in the central direction to achieve flexible adjustment. The top of the adjustment ring 101 is connected with the combustion chamber 2, and the combustion chamber 2 is in the shape of a "cylinder", which is more stable. The outer wall of the combustion chamber 2 is sleeved with a cleaning swivel 202. The cleaning swivel The interior of 202 is connected with an ignition tube 203, and the ignition tube 203 is made of high temperature resistant insulating material to ensure the safety of the device. The end of the ignition tube 203 away from the cleaning swivel 202 is sleeved with an ignition control button 204, and the gas mixing chamber 1 is far away from the adjustment One side of ...

Embodiment 3

[0032] In an embodiment, an energy-saving and environment-friendly gas burner includes a gas mixing chamber 1, a combustion chamber 2, and a blower 3. An adjusting ring 101 is sleeved above the gas mixing chamber 1, and the adjusting ring 101 can move along the axis of the gas mixing chamber 1. Rotate in the central direction to achieve flexible adjustment. The top of the adjustment ring 101 is connected with the combustion chamber 2, and the combustion chamber 2 is in the shape of a "cylinder", which is more stable. The outer wall of the combustion chamber 2 is sleeved with a cleaning swivel 202. The cleaning swivel The interior of 202 is connected with an ignition tube 203, and the ignition tube 203 is made of high temperature resistant insulating material to ensure the safety of the device. The end of the ignition tube 203 away from the cleaning swivel 202 is sleeved with an ignition control button 204, and the gas mixing chamber 1 is far away from the adjustment One side of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com