Preparation method of sensitive thin-film with sandwich structure

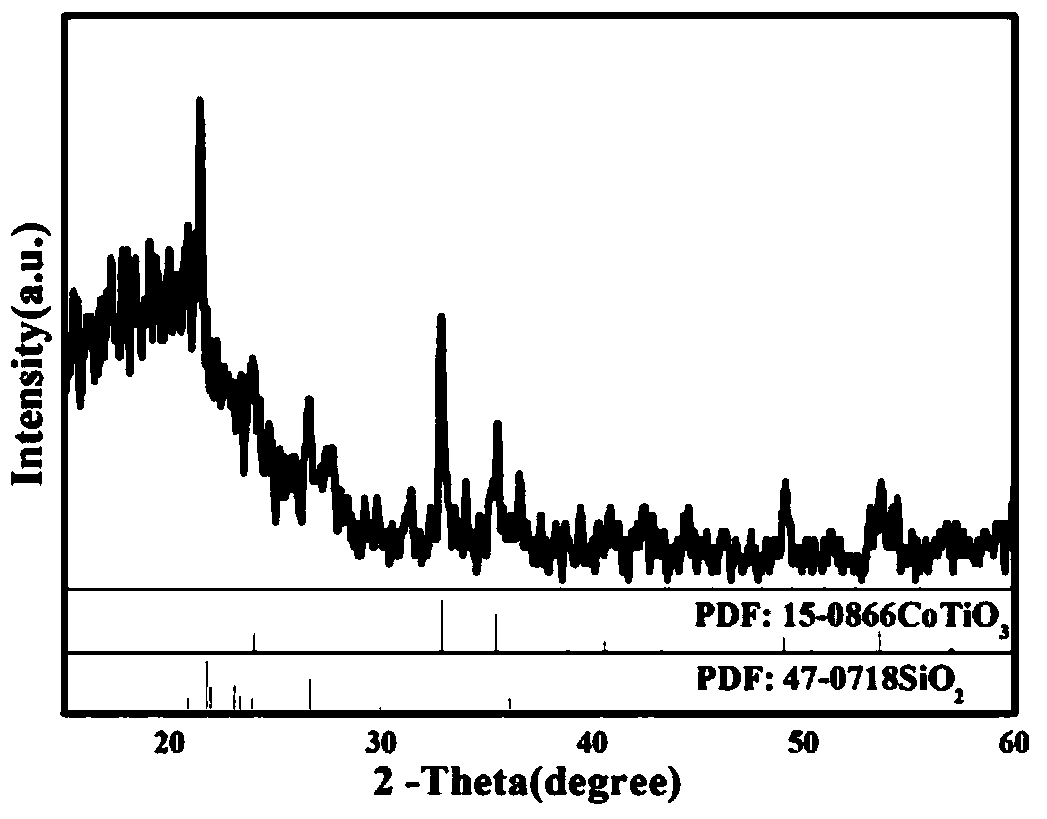

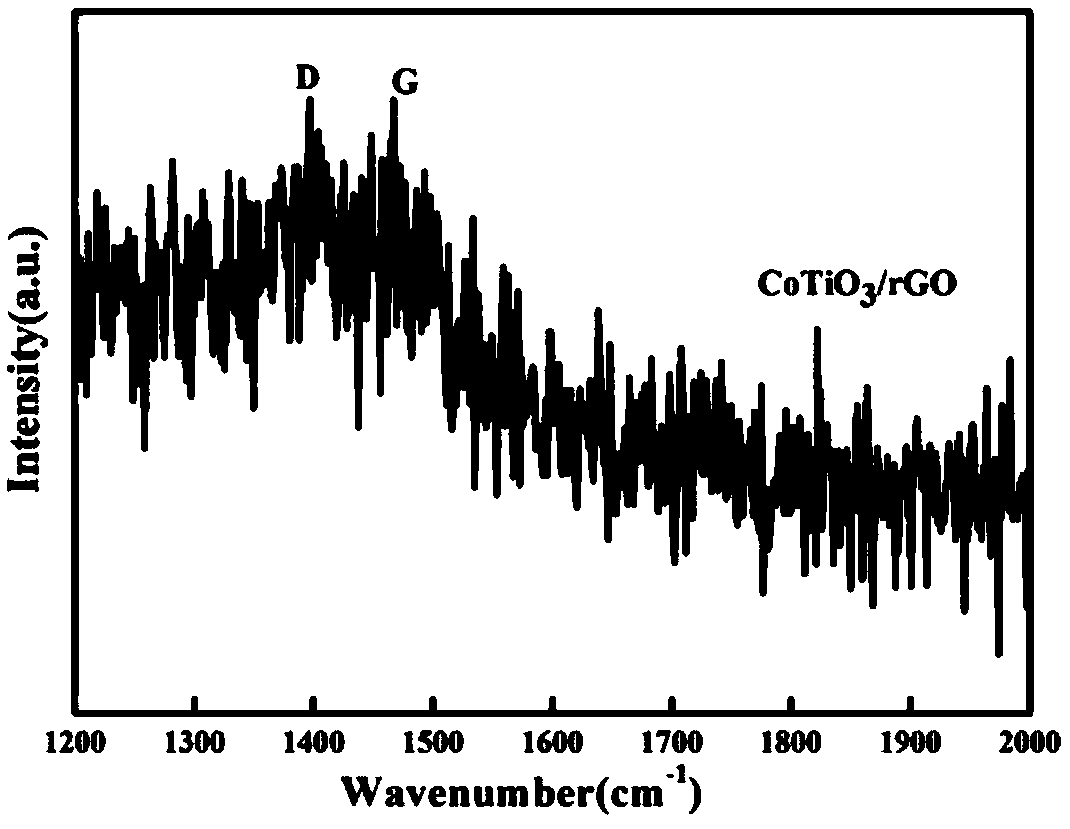

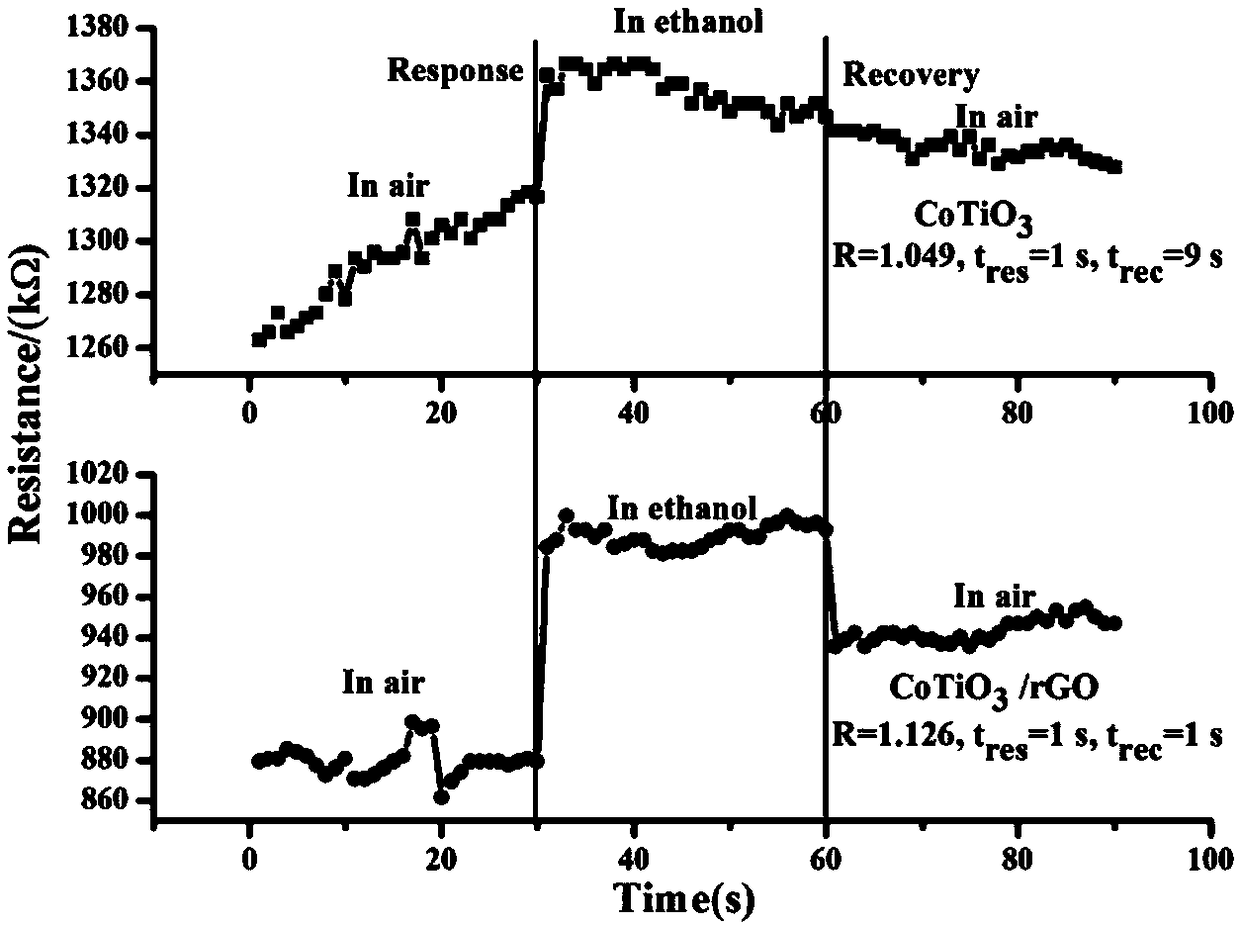

A technology of sensitive thin film and sandwich structure, applied in measurement devices, instruments, material analysis by electromagnetic means, etc., can solve the problem of unsatisfactory response speed, degree of response and selectivity, small sensor specific surface area, large sensor volume, etc. problem, to achieve the effect of strong surface activity, short response recovery time, and excellent conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] 1) Prepare the sol: dissolve cobalt chloride in absolute ethanol, then slowly add isobutyl titanate dropwise, stir evenly with a magnetic force, adjust the pH value to 2.0 with glacial acetic acid to obtain a mixed solution, and add Co 2+ Concentration is 0.1mol / L, Ti 4+The concentration is 0.05mol / L. The mixed solution was reacted in a water bath at 50°C for 30min to obtain CoTiO 3 Precursor solution A.

[0037] 2) Evenly disperse graphene oxide (GO) in absolute ethanol, pretreat with 100W ultrasonic wave for 10min, and obtain ethanol suspension B of graphene oxide, wherein the concentration of graphene oxide in ethanol is 0.5mg / mL;

[0038] 3) Coating on the surface of the clean Si substrate by immersion-pulling method, first dip the Si substrate in CoTiO 3 In the precursor solution A, the immersion time was 1 min, and then pulled at a uniform speed at a controlled pulling rate of 0.5 mm / s, and then the film was dried in an oven at a controlled drying temperature o...

Embodiment 2

[0044] 1) Prepare the sol: dissolve cobalt chloride in absolute ethanol, then slowly add isobutyl titanate dropwise, stir evenly with a magnetic force, adjust the pH value to 4.0 with glacial acetic acid to obtain a mixed solution, and add Co 2+ Concentration is 0.1mol / L, Ti 4+ The concentration is 0.1mol / L. The mixed solution was reacted in a 40°C water bath for 60min to obtain CoTiO 3 Precursor solution A.

[0045] 2) Evenly disperse graphene oxide (GO) in absolute ethanol, pretreat with 100W ultrasonic wave for 10min, and obtain ethanol suspension B of graphene oxide, wherein the concentration of graphene oxide in ethanol is 1mg / mL;

[0046] 3) Coating on the surface of the clean Si substrate by immersion-pulling method, first dip the Si substrate in CoTiO 3 In the precursor solution A, the immersion time was 1 min, and then pulled at a uniform speed at a controlled pulling rate of 1 mm / s, and then the film was dried in an oven at a controlled drying temperature of 40°C ...

Embodiment 3

[0054] 1) Prepare the sol: dissolve cobalt chloride in absolute ethanol, then slowly add isobutyl titanate dropwise, stir evenly with a magnetic force, adjust the pH value to 5.0 with glacial acetic acid to obtain a mixed solution, and add Co 2+ Concentration is 0.2mol / L, Ti 4+ The concentration is 0.2mol / L. The mixed solution was reacted in a 60°C water bath for 50min to obtain CoTiO 3 Precursor solution A.

[0055] 2) Evenly disperse graphene oxide (GO) in absolute ethanol, pretreat with 100W ultrasonic wave for 20min, and obtain ethanol suspension B of graphene oxide, wherein the concentration of graphene oxide in ethanol is 1.5mg / mL;

[0056] 3) Coating on the surface of the clean Si substrate by immersion-pulling method, first dip the Si substrate in CoTiO 3 In the precursor solution A, the immersion time was 1 min, and then pulled at a uniform speed at a controlled pulling rate of 5 mm / s, and then the film was dried in an oven at a controlled drying temperature of 20°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com