Method for qualitatively predicting service life of lithium ion battery using EIS test

A lithium-ion battery, life-span technology, applied in the direction of measuring electricity, measuring electrical variables, measuring devices, etc., can solve the problems of complex calculation principles and calculation processes, large errors, etc., and achieve high accuracy, high efficiency, and adaptability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

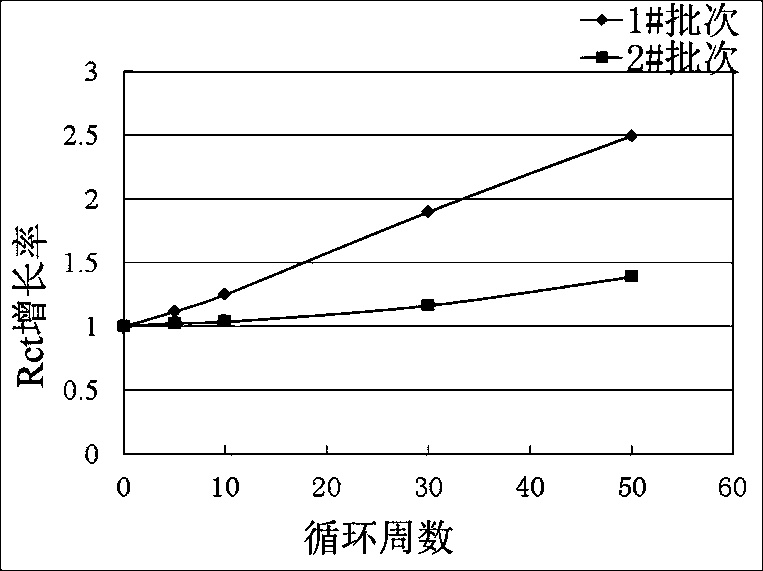

[0032] Select two batches of 18650 cells as the cells to be tested, numbered 1# batch and 2# batch, the difference between 1# batch and 2# batch is the negative electrode material used. Divide the battery cells to be tested for 5 weeks first to ensure that the cells to be tested are fully charged and have no overcharge.

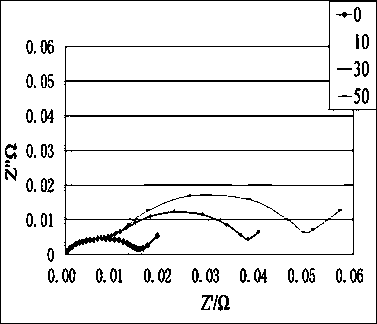

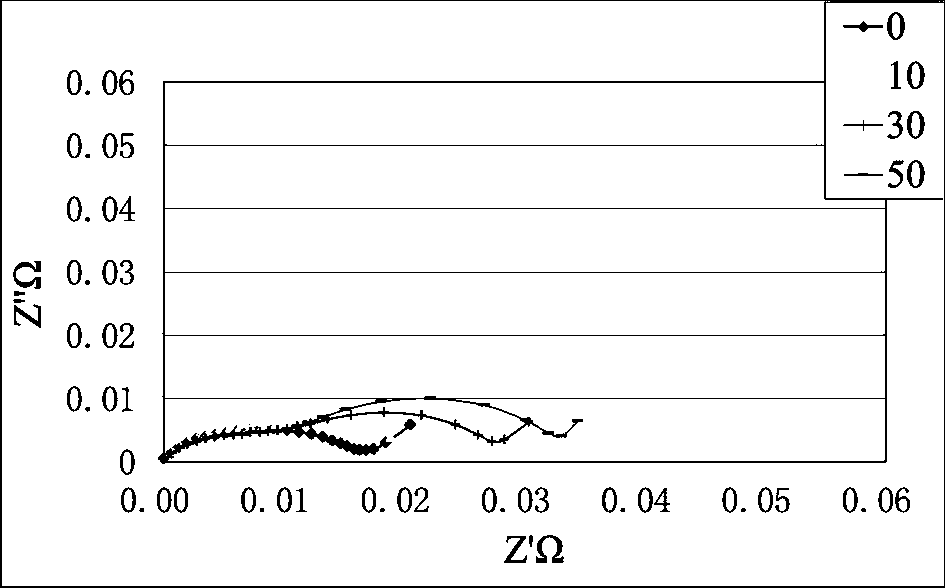

[0033] S01, heat the cells to be tested in a constant temperature box at 40°C for 5 hours, then place the cells to be tested on the test fixture one by one for EIS testing, and do not take out the cells to be tested from the constant temperature box during the test; EIS The tested frequency range is 0.05-10 5 Hz, the EIS test is completed within 2 hours.

[0034] S02, cycle the battery cell after the EIS test in S01 at a temperature of 60°C, the cycle system is a charge-discharge cycle of 0.5C charge and 0.5C discharge, and the cycle number is 0, 10, 30, 50;

[0035] S03, place the cells after the cycle in S02 in a constant temperature box at 40°C for 5 hou...

Embodiment 2

[0043] Select two batches of 18650 cells as the cells to be tested, numbered 3# batch and 4# batch, the difference between 3# batch and 4# batch is the positive electrode material used. Experimental method is with embodiment 1.

[0044] attached Figure 4 It is the change curve of the Rct growth rate of the battery cells to be tested in the 3# batch and the 4# batch in this embodiment with the number of cycles.

[0045] attached Figure 8 In this example, 3# batches and 4# batches of batteries to be tested are charged and discharged at a rate of 0.5C under normal temperature conditions, and the battery capacity retention rate varies with the number of cycles.

[0046] attached by Figure 4 It can be seen that the Rct growth rate of the 4# batch of cells to be tested is faster than that of the 3# batch of cells to be tested, indicating that the cycle performance of the cells to be tested in the 4# batch is poor. attached by Figure 8 It can be seen that under normal temper...

Embodiment 3

[0049] Select two batches of 18650 cells as the cells to be tested, numbered 5# batch and 6# batch, the difference between 5# batch and 6# batch is the negative electrode material used. Experimental method is with embodiment 1.

[0050] attached Figure 5 It is the change curve of the Rct growth rate of the battery cells to be tested in the 5# batch and the 6# batch in this embodiment with the number of cycles.

[0051] attached Figure 9 In this example, the 5# batches and 6# batches of cells to be tested are charged and discharged at a rate of 0.5C under normal temperature conditions, and the capacity retention rate of the cells varies with the number of cycles.

[0052] attached by Figure 5 It can be seen that the Rct growth rate of the 6# batch of cells to be tested is faster than that of the 5# batch of cells to be tested, indicating that the cycle performance of the cells to be tested in the 6# batch is poor. attached by Figure 9 It can be seen that under normal t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com