A surface miniature piezoelectric power generation device

A piezoelectric power generation and miniature technology, applied in the direction of generators/motors, piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, etc., can solve the difficulty of collecting, storing and reusing micro-machines, and restrict piezoelectricity The development and application of power generation technology, poor cycle performance and other problems, to achieve the effect of excellent cycle compressibility, good power generation effect, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

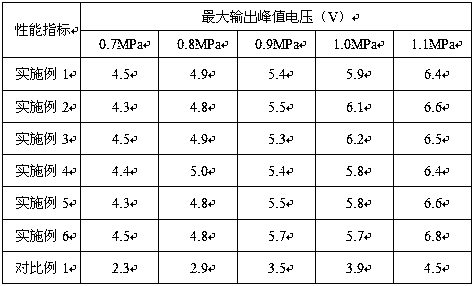

Examples

Embodiment 1

[0029] The road micro piezoelectric power generation device is composed of an upper cover, a lower cover, an electromechanical conversion unit, and an air cushion; the electromechanical conversion unit is a metal sheet surrounded by piezoelectric ceramics-polyurethane sponge composite material, and the electromechanical conversion unit is electrically connected to an output end; the air cushion is set under the micro piezoelectric sheet to provide a deformation space for the micro piezoelectric ceramic-polyurethane sponge.

[0030] The preparation process of the piezoelectric ceramic-polyurethane sponge composite material is as follows:

[0031] Add 26kg of nano-potassium sodium metaniobate powder to 71g of water, then add 3kg of sodium methylene bis-naphthalene sulfonate, stir at a high speed of 950r / min, and ultrasonically disperse for 30min at an ultrasonic frequency of 105kHz to obtain nano-piezoelectric Dispersion glue of ceramic powder material; then the polyurethane spo...

Embodiment 2

[0036] The road micro piezoelectric power generation device is composed of an upper cover, a lower cover, an electromechanical conversion unit, and an air cushion; the electromechanical conversion unit is a metal sheet surrounded by piezoelectric ceramics-polyurethane sponge composite material, and the electromechanical conversion unit is electrically connected to an output end; the air cushion is set under the micro piezoelectric sheet to provide a deformation space for the micro piezoelectric ceramic-polyurethane sponge.

[0037] The preparation process of the piezoelectric ceramic-polyurethane sponge composite material is as follows:

[0038] Add 20kg of nano barium strontium metaniobate powder into 78kg of water, then add 2kg of sodium methylene bismethyl naphthalene sulfonate, stir at a high speed of 800r / min, and ultrasonically disperse at an ultrasonic frequency of 80kHz for 50min to obtain nano Dispersion glue of piezoelectric ceramic powder material; then the polyuret...

Embodiment 3

[0041]The road micro piezoelectric power generation device is composed of an upper cover, a lower cover, an electromechanical conversion unit, and an air cushion; the electromechanical conversion unit is a metal sheet surrounded by piezoelectric ceramics-polyurethane sponge composite material, and the electromechanical conversion unit is electrically connected to an output end; the air cushion is set under the micro piezoelectric sheet to provide a deformation space for the micro piezoelectric ceramic-polyurethane sponge.

[0042] The preparation process of the piezoelectric ceramic-polyurethane sponge composite material is as follows:

[0043] Add 30kg of nanometer lead zirconate titanate powder into 66kg of water, then add 4kg of polyethylene glycol, stir at a high speed of 1200r / min, and ultrasonically disperse for 20min at an ultrasonic frequency of 120kHz to obtain nano piezoelectric ceramic powder materials. Disperse the glue; then clean the polyurethane sponge with deio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com