Iron-based metallic glass alloy powder

An iron-based metal and glass alloy technology, which is applied in metal processing equipment, magnetic objects, transportation and packaging, etc., can solve the problem of easy ignition of iron-based metal glass alloy powder.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

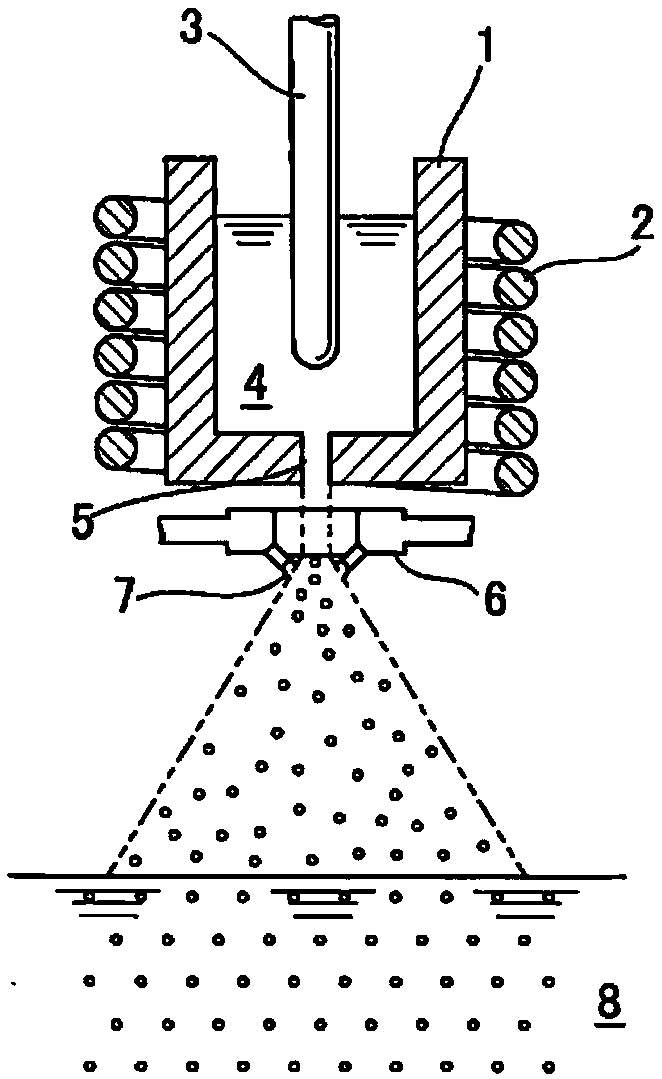

[0167] The basic composition and the corrosion resistance modifying component were adjusted so that the corrosion resistance modifying component had the content shown in the table below, and the obtained material mixture was melted in a high-frequency induction furnace, and passed through the water mist under the following conditions: Chemical method to obtain powder with the target composition.

[0168]

[0169] ·Water pressure: 100MPa

[0170] ·Water volume: 100L / min

[0171] ·Water temperature: 20℃

[0172] ·Orifice diameter: φ4mm

[0173] ·Molten raw material temperature: 1500℃

[0174] The obtained iron-based metallic glass alloy powder was classified as D using an airflow classifier (manufactured by Nisshin Engineering Inc.: TUURBO CLASSIFIER). 50 = 2 ± 0.3 μm. The particle size was measured with a laser diffraction particle size distribution analyzer (manufactured by NIKKISO CO., LTD.: Microtrac MT3300EX II (wet type)). The content rate of a semimetal element an...

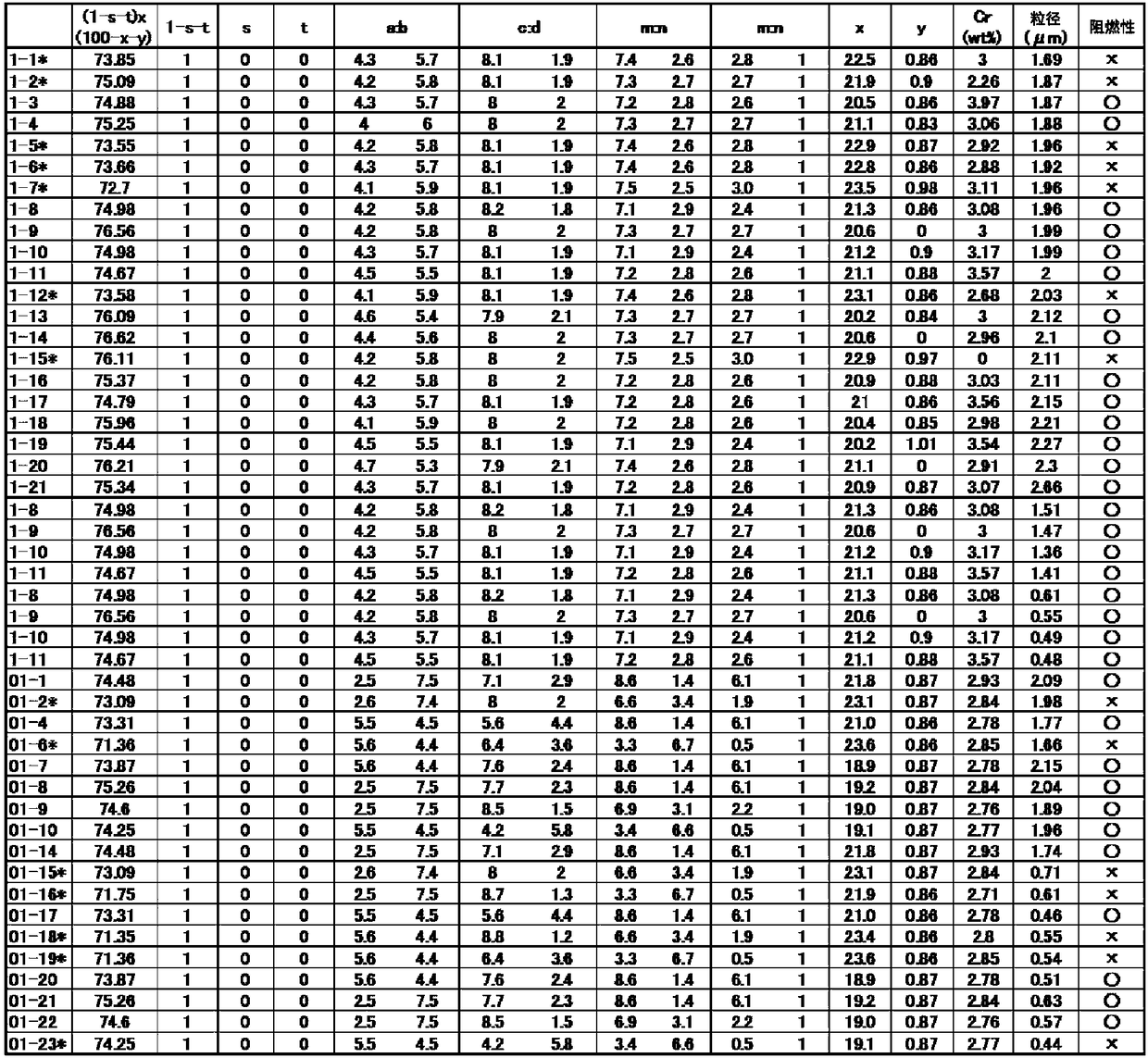

no. 1 approach

[0182]

[0183] [Table 2]

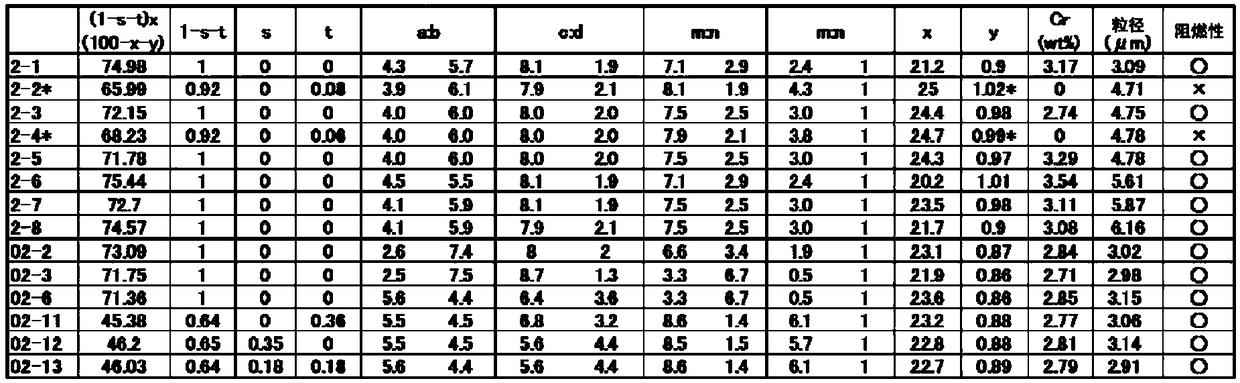

no. 2 approach

[0185]

[0186] [table 3]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com