Preparation method of modified MMT (montmorillonite)/ZnO/GQDs (graphene quantum dots) nano-composite antibacterial agent

A nanocomposite and antibacterial agent technology is applied in the field of preparation of modified MMT/ZnO/GQDs nanocomposite antibacterial agents, which can solve the problems of unsatisfactory antibacterial activity of modified MMT and achieve high antibacterial activity, good biocompatibility, Resistant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

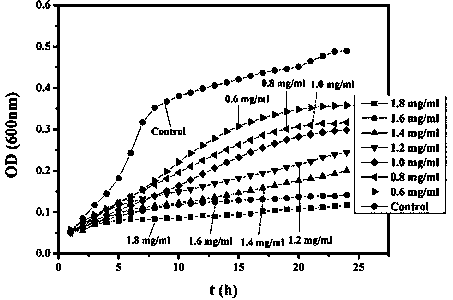

Image

Examples

preparation example Construction

[0027] A preparation method of modified MMT / ZnO / GQDs nanocomposite antibacterial agent, comprising the following steps:

[0028] Step 1: Preparation of modified montmorillonite (modified MMT):

[0029] Weigh 5-20g sodium-based montmorillonite and disperse in 200ml deionized water, stir at 80°C for 30min at high speed; disperse 2-14g modifier in 50ml deionized water, after it is completely dissolved, add sodium-based montmorillonite In the dispersion, stir at 80°C for 2 hours at a high speed, let it stand for 2 hours to cool down, and then use a vacuum filter device to repeatedly filter it, dry it, and grind it to obtain the modified montmorillonite (modified MMT);

[0030] Step 2: Preparation of GQDs solution:

[0031] Put 1-10g of citric acid (CA) into a 50ml beaker, heat and react to obtain an orange liquid; then, adjust the pH to 7.0 with aqueous sodium hydroxide solution, dialyze for 24 hours, and rotate to evaporate to obtain the GQDs solution;

[0032] Step 3: Preparat...

Embodiment 1

[0043] Step 1: Preparation of modified montmorillonite (modified MMT):

[0044] Weigh 8.5g of sodium montmorillonite and disperse it in 200ml of deionized water, stir at 80°C for 30min at high speed; In the base montmorillonite dispersion, stir at 80°C for 2 hours at high speed, let it stand for 2 hours to cool down, and then use a vacuum filter to filter it repeatedly, dry it at 100°C for 24 hours, and grind it into a fine powder to obtain the modified Montmorillonite;

[0045] Step 2: Preparation of GQDs solution:

[0046] Take 4g of citric acid (CA) into a 50ml beaker, heat to 200°C and react for 30 minutes to obtain an orange liquid; then, adjust the pH to 7.0 with aqueous sodium hydroxide solution, dialyze for 24 hours, and rotate to evaporate to obtain the GQDs solution;

[0047] Step 3: Preparation of modified MMT / ZnO / GQDs composite nanocomposite antibacterial agent:

[0048] Add 0.65g of sodium hydroxide into 50ml of ethanol solution, stir magnetically for 30min, an...

Embodiment 2

[0050] Step 1: Preparation of modified montmorillonite (modified MMT):

[0051]Weigh 12.0g of sodium montmorillonite and disperse it in 200ml of deionized water, stir at 80°C for 30min at high speed; In the base montmorillonite dispersion, stir at 80°C for 2 hours at high speed, let it stand for 2 hours to cool down, and then use a vacuum filter to filter it repeatedly, dry it at 100°C for 24 hours, and grind it into a fine powder to obtain the modified Montmorillonite;

[0052] Step 2: Preparation of GQDs solution:

[0053] Take 2g of citric acid (CA) into a 50ml beaker, heat to 200°C and react for 30 minutes to obtain an orange liquid; then, adjust the pH to 7.0 with aqueous sodium hydroxide solution, dialyze for 24 hours, and rotate to evaporate to obtain the GQDs solution;

[0054] Step 3: Preparation of modified MMT / ZnO / GQDs composite nanocomposite antibacterial agent:

[0055] Add 0.75g of sodium hydroxide into 50ml of ethanol solution, stir magnetically for 30min, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com