Preparation method and application of minced shrimp material for 3D printing

A technology of 3D printing and minced shrimp products, applied in food ingredients as taste improver, food science and other directions, can solve the problem of lack of 3D printing materials, and achieve the effect of timely discharge, high precision and good taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A preparation method for 3D printing shrimp paste material, comprising the following steps:

[0036] S1. Raw material pretreatment: remove the sediment, shrimp head, shrimp shell and shrimp thread from the vannamei shrimp, wash with 0°C water, and drain;

[0037] S2, minced meat: cooling the shrimp meat obtained in step S1 at 4°C for 20 minutes, using a meat grinder with a meat grinder orifice diameter of 3 mm, and minced the meat at 0°C to obtain minced shrimp meat;

[0038] S3. Prepare minced shrimp: add the minced shrimp meat obtained in step S3 to starch and chop at 0°C. The chopping is carried out in three steps, and the chopping speed is 1400rpm:

[0039] Once chopped and mixed: take 100 parts by weight of the minced shrimp meat prepared in step S3, add 2 parts by weight of salt, 0.2 parts by weight of composite phosphate, and 35 parts by weight of ice-water mixture, chop and mix for 40 seconds, stop for 30 seconds, and chop and mix for 10 minutes (stop The time ...

Embodiment 2

[0043] A preparation method for 3D printing shrimp paste material, comprising the following steps:

[0044] S1. Raw material pretreatment: remove the silt, shrimp head, shrimp shell and shrimp line from the green shrimp, wash with 10°C water, and drain;

[0045] S2, minced meat: cooling the shrimp meat obtained in step S1 at 4°C for 40 minutes, using a meat grinder with a meat grinder orifice diameter of 6 mm, minced the meat at 10°C to obtain minced shrimp meat;

[0046] S3. Prepare minced shrimp: add the minced shrimp meat obtained in step S3 to starch and chop at 10°C. The chopping is carried out in three steps, and the chopping speed is 3000rpm:

[0047] Once chopping and mixing: take 120 parts by weight of minced shrimp meat prepared in step S3, add 4 parts by weight of salt, 0.5 parts by weight of composite phosphate, and 30 parts by weight of ice-water mixture, chop and mix for 60 seconds, stop for 30 seconds, and chop and mix for 15 minutes (stop The time is not count...

Embodiment 3

[0051] A preparation method for 3D printing shrimp paste material, comprising the following steps:

[0052] S1. Raw material pretreatment: Remove the sediment, shrimp head, shrimp shell and shrimp line from the Chinese prawns, wash them with 4°C water, and drain;

[0053] S2, minced meat: cooling the shrimp meat obtained in step S1 at 4°C for 30 minutes, using a meat grinder with a meat grinder orifice diameter of 4mm, minced the meat at 4°C to obtain minced shrimp meat;

[0054] S3. Prepare minced shrimp: add the minced shrimp meat obtained in step S3 to starch and chop at 4°C. The chopping is carried out in three steps, and the chopping speed is 2200rpm:

[0055] Once chopped and mixed: take 110 parts by weight of the minced shrimp meat prepared in step S3, add 3 parts by weight of salt, 0.3 parts by weight of compound phosphate, and 20 parts by weight of ice-water mixture, cut and mix for 50s every time, stop for 30s, and chop and mix for 12min (stop The time is not counte...

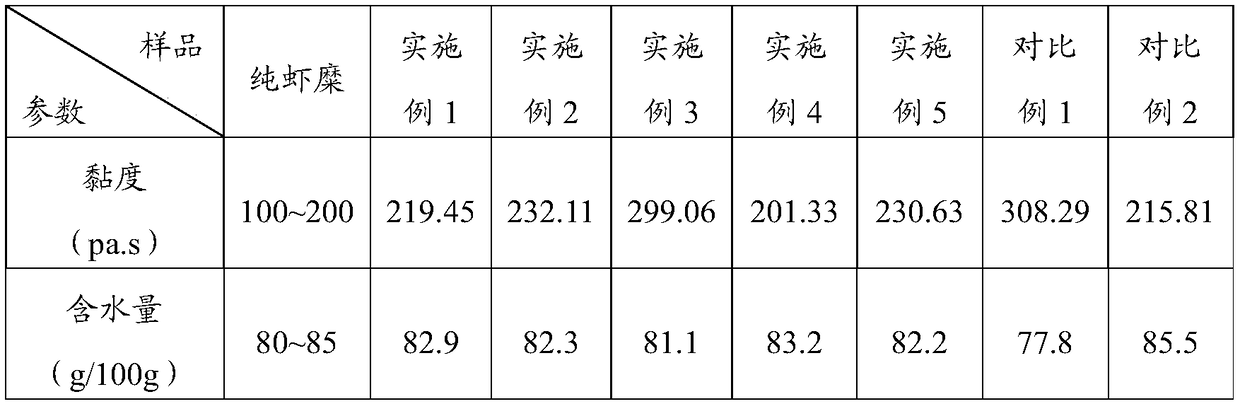

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com