Heating cup

A technology for heating cups and heating components, which is applied in the field of heating cups, which can solve the problems of electric leakage, long time for heating cups to high temperature, etc., and achieve the effect of improving heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

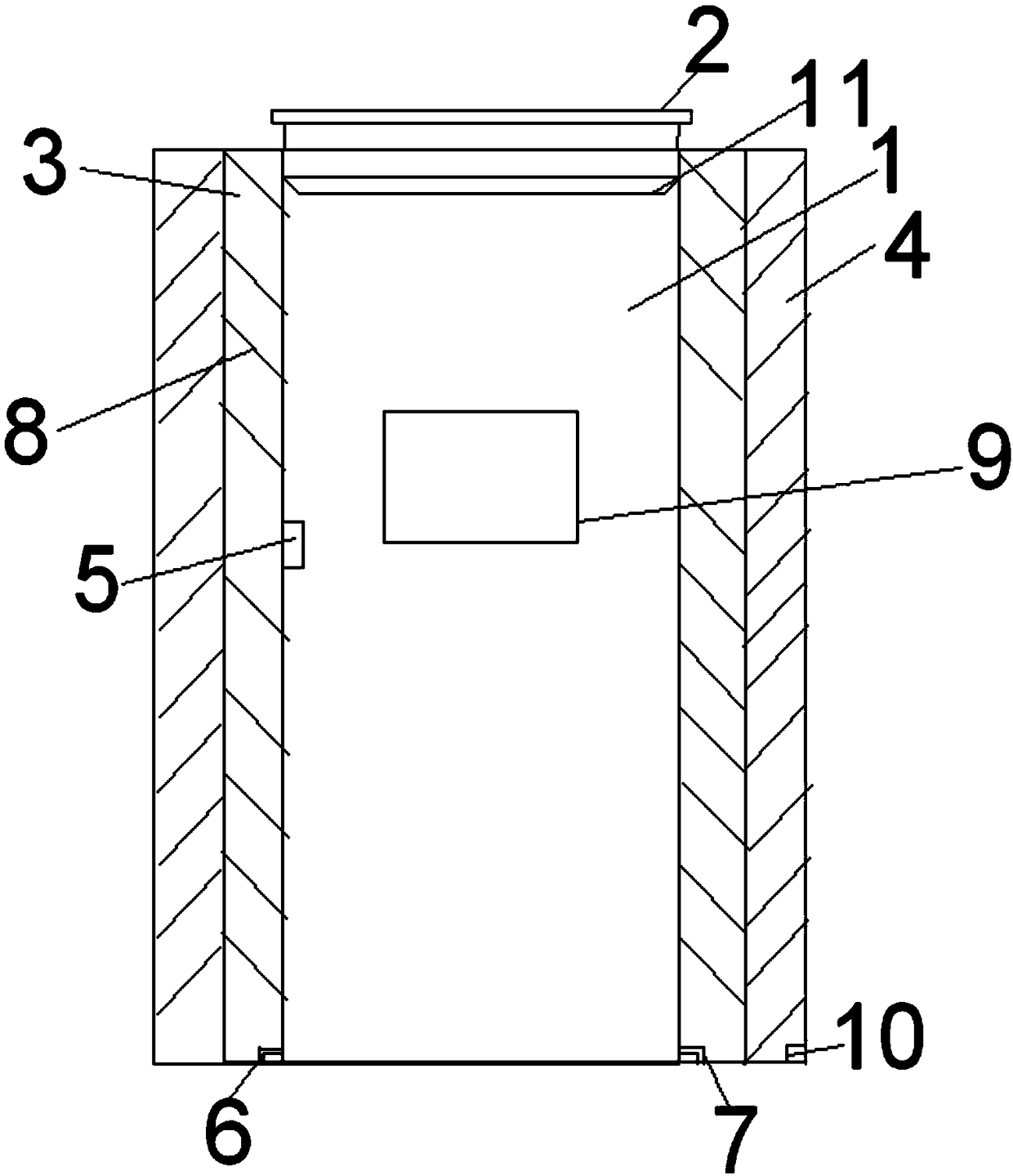

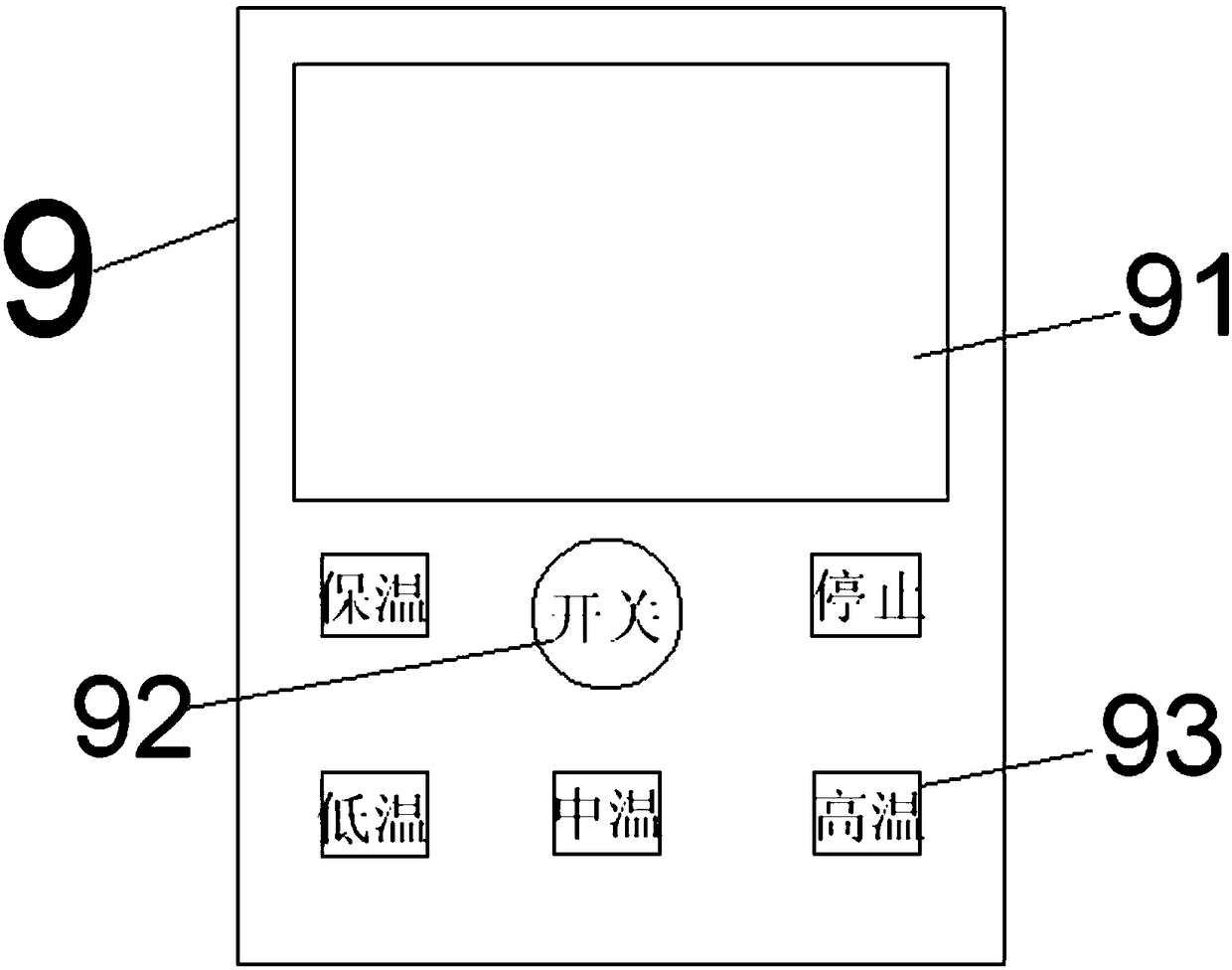

[0023] Such as figure 1 As shown, a heating cup has a cup body capacity of 400ml, including a cup body, a cup cover 2, a temperature sensor 5, a controller 10, a control display screen 9 and a heating assembly; 4 is closely connected with the cup body 1, and a cavity 3 is provided between the heat insulation layer 4 and the cup body 1; the cup body 1 is hollow cylindrical and made of aluminum-iron alloy; the cup mouth of the cup body 1 and The cup cover 2 is connected by threads; the temperature sensor 5 is located in the middle of the inner wall of the cup body 1 and is electrically connected to the control display screen 9; the temperature sensor 5 detects the average temperature in the cup body 1 and converts it into an electrical signal and sends it to the control panel. device 10; the heating assembly is arranged in the cavity 3, including an electric heating coil 6, a sealed and insulated coil sleeve 7 and a heat-conducting medium 8; the electric heating coil 6 is fixed ...

Embodiment 2

[0031] The same structure and working principle as in Embodiment 1, the difference is:

[0032] The capacity of the heating cup is 450ml.

[0033] Electrolyte water is prepared by mixing and stirring 300ml pure water and 125ml 40% sodium hydroxide solution at 55°C.

[0034] The preparation steps of the sealed insulating coil cover include:

[0035] (1) Take by weight 140 parts of polyethylene, 38 parts of kaolin, 40 parts of nano-alumina powder, 16 parts of diamond powder, 13 parts of magnesium oxide powder, 10 parts of carbon powder, polyether modified siloxane flow promotion 6 parts of agent, 2 parts of tetradecyltrimethylammonium bromide, 8 parts of dilute hydrochloric acid, 75 parts of n-butyl ether;

[0036] (2) Dissolve nano-alumina powder, magnesium oxide powder and carbon powder in n-butyl ether, shear and stir for 2-5 hours to form a suspension, add tetradecyltrimethylammonium bromide, and continue stirring at 250r / min 5.5h, add dilute hydrochloric acid near the en...

Embodiment 3

[0039] The same structure and working principle as in Embodiment 1, the difference is:

[0040] The capacity of the heating cup is 500ml.

[0041] Electrolyte water is prepared by mixing and stirring 300ml of pure water and 150ml of 40% sodium hydroxide solution at 60°C.

[0042] The preparation steps of the sealed insulating coil cover include:

[0043] (1) Take by weight 180 parts of polyethylene, 50 parts of kaolin, 50 parts of nano-alumina powder, 20 parts of diamond powder, 16 parts of magnesium oxide powder, 12 parts of carbon powder, polyether modified siloxane flow promotion 7 parts of agent, 3 parts of tetradecyltrimethylammonium bromide, 10 parts of dilute hydrochloric acid, 90 parts of n-butyl ether;

[0044] (2) Dissolve nano-alumina powder, magnesium oxide powder and carbon powder in n-butyl ether, shear and stir for 5 hours to form a suspension, add tetradecyltrimethylammonium bromide, and continue stirring at 300r / min for 4 hours, Add dilute hydrochloric acid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com