Waste gas treatment system for lead-acid storage batteries and application method of waste gas treatment system

A lead-acid battery and waste gas treatment technology, applied in separation methods, chemical instruments and methods, and dispersed particle separation, etc., can solve problems such as air pollution, and achieve the effect of reducing emission concentration and improving waste gas purification efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

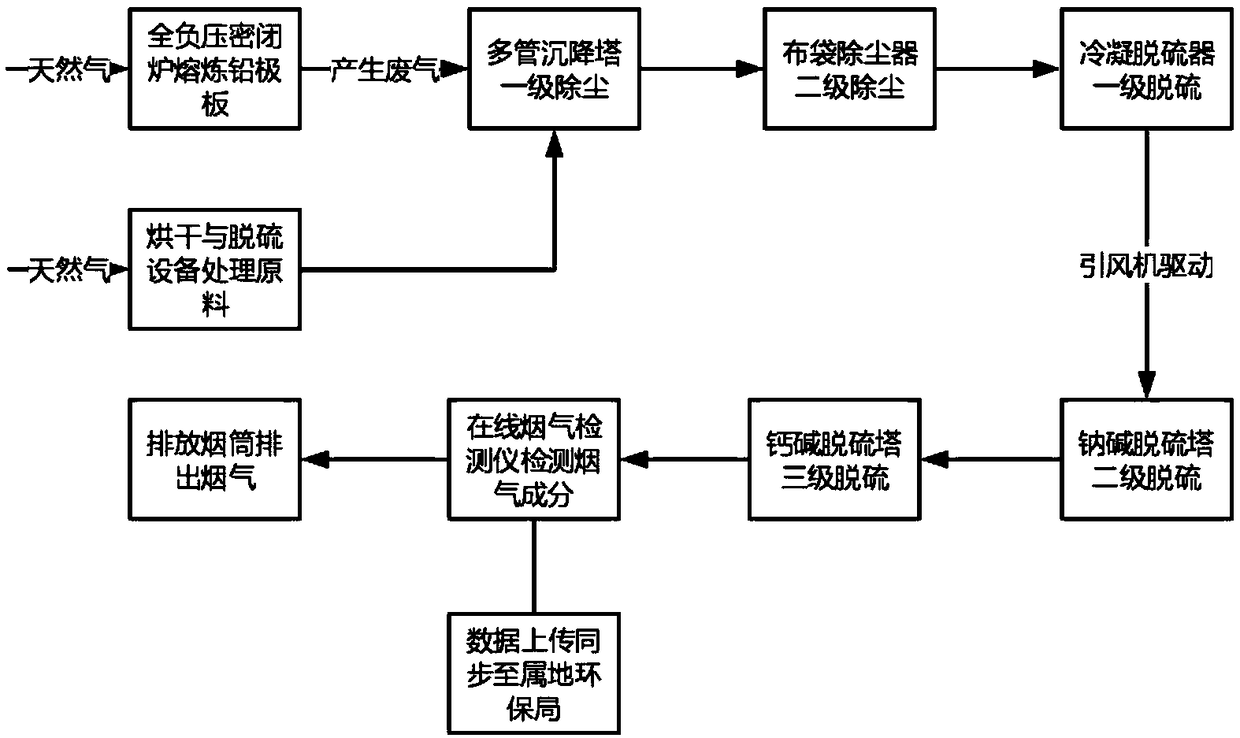

[0025] This embodiment provides a waste gas treatment system for lead-acid batteries, such as figure 1 As shown, it includes the closed gas collection system 1 and the exhaust gas purification system 2. The two are integrated and connected, and each device in the system cannot operate independently. In addition, the system also includes drying and pre-desulfurization equipment 3 that can operate independently, which is used for pretreatment before the raw materials are put into the furnace. The pretreatment process adopts countercurrent negative pressure sealing technology, and the entire production process is fully negative pressure operation without any leakage of smoke.

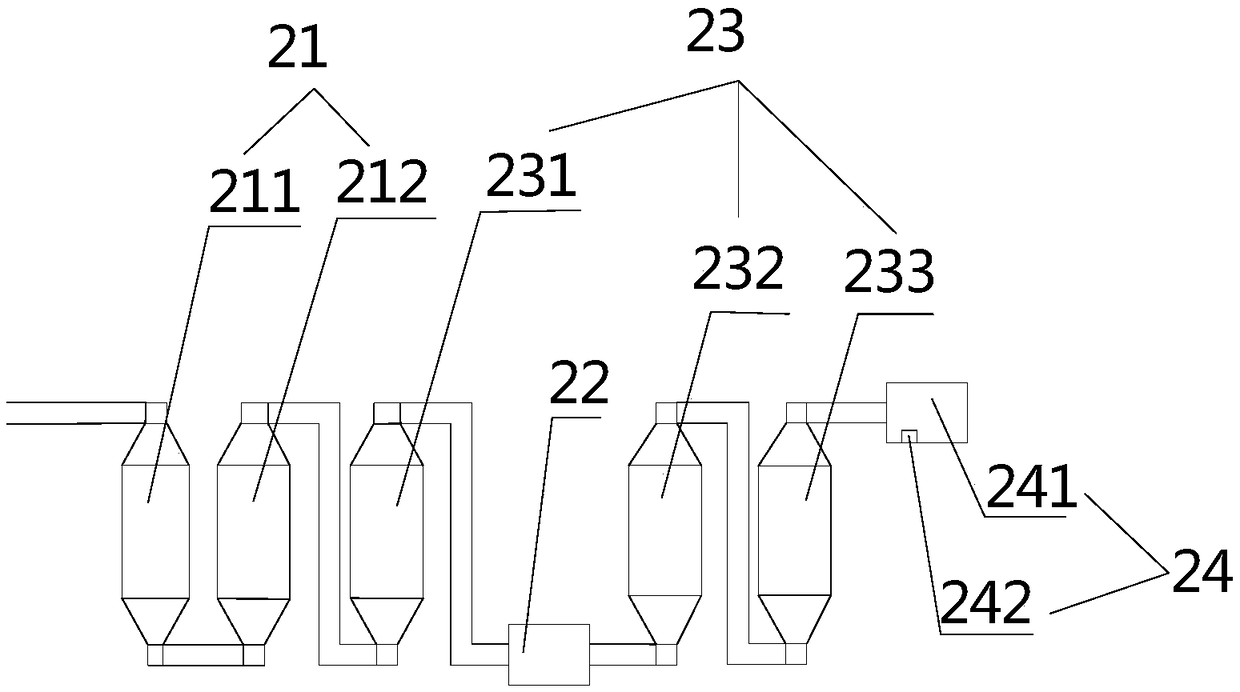

[0026] Among them, the closed gas collection system 1 is a full negative pressure closed furnace, which is used to smelt the lead plates of waste lead-acid batteries. Open the furnace door and cause exhaust gas to leak out. The exhaust gas purification system 2 includes a dust removal system 21 , a power...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap