Treatment method of waste plastics for reuse

A technology of waste plastics and treatment methods, which is applied in the field of recycling waste plastics, can solve the problems of high transportation costs of waste, secondary pollution of the environment, air pollution, etc., and achieves the effects of convenient operation, solving pollution problems, and reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Example 1, use a shredder to process waste plastics into plastic fragments with a size of 3-5cm in length and 3-5cm in width; stir and dry at low temperature, the drying temperature is 50°C, the stirring rate is 80 rpm, and the drying The time is 10 minutes. Use a pulverizer to crush the dried plastic fragments into plastic fragments with a size of 2-3mm and 2-3mm in width; mix the plastic fragments with fine sand and high-strength cement, add appropriate amount of water and stir with a mixer, The stirring rate is 25 rev / min, the stirring time is 20min, the mass percentage of plastic powder is 5%, the mass percentage of fine sand is 25%, and the mass percentage of high-strength cement is 70%; Stir the resulting mixture and extrude to 1 cm 3 Spherical body of about size; the extruded product is used as concrete aggregate after solidification, and its compressive strength is 35-40MPa.

Embodiment 2

[0016] Example 2, the discarded plastics are concentrated and treated with a shredder to grow 3-5cm long and 3-5cm wide plastic fragments; low-temperature stirring and drying, the drying temperature is 40°C, the stirring rate is 50 rpm, and the drying The time is 10 minutes. Use a pulverizer to crush the dried plastic fragments into plastic fragments with a size of 2-3mm and 2-3mm in width; mix the plastic fragments with fine sand and high-strength cement, add appropriate amount of water and stir with a mixer, The stirring rate is 35 rev / min, the stirring time is 20min, the mass percentage of plastic powder is 8%, the mass percentage of fine sand is 22%, and the mass percentage of high-strength cement is 70%; Stir the resulting mixture and extrude to 1 cm 3 Spheroids of about size; extruded products are used as coagulation aggregates after solidification, and their compressive strength is 30-35MPa.

Embodiment 3

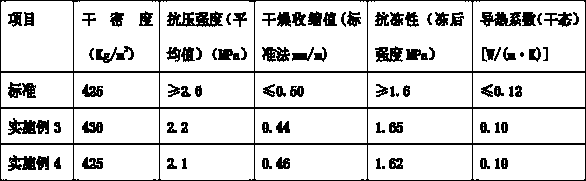

[0017] Example 3, use a shredder to process the discarded plastics together into plastic fragments with a size of 3-5cm and a width of 3-5cm; stir and dry at low temperature, the drying temperature is 45°C, and the stirring rate is 65 rpm. The machine crushes the dried plastic fragments into plastic fragments with a size of 2-3mm and a width of 2-3mm; the shredder shreds the dried plastic fragments again to a size of 1-2cm in length and 1-2cm in width Plastic fragments are added to the air-entrained concrete slurry at a mass ratio of 10%, and the air-entrained concrete block is made after being stirred evenly, and the stirring rate is 25 rpm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com