Integral prefabricated steel plate composite beam structure and construction method

A technology of overall prefabrication and prefabrication of beams, applied in bridges, bridge construction, bridge parts, etc., can solve problems such as large workload on site, difficult construction, and difficult quality control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

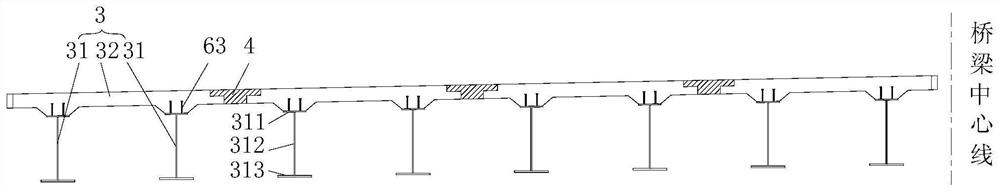

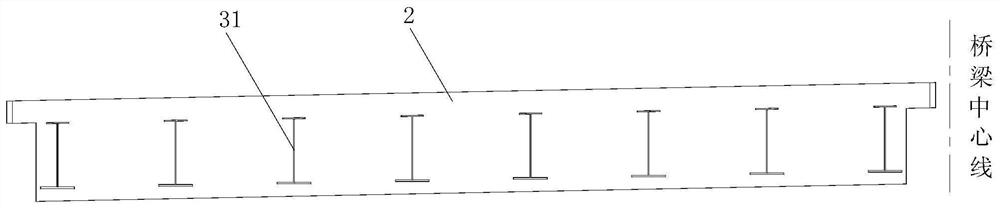

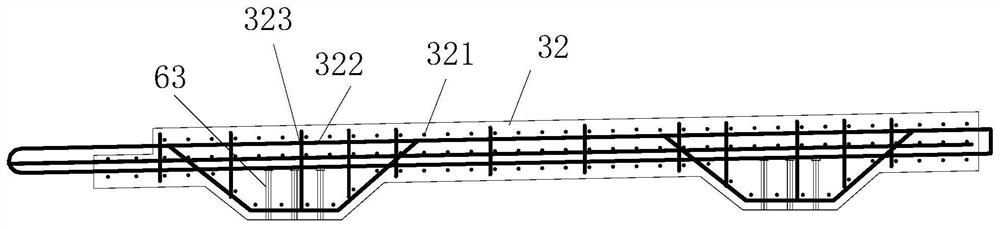

[0038] Figure 1 to Figure 9 An embodiment of the integrally prefabricated steel plate composite girder of the present invention is shown.

[0039] Specific as figure 1 As shown, the steel longitudinal beam 31 (also known as the steel main beam) is 2.1m apart, and adopts a standard I-shaped section, including a steel longitudinal beam top plate 311, a steel longitudinal beam web plate 312, and a steel longitudinal beam bottom plate 313. The steel longitudinal beam 31 Beam height 1180mm (that is to say the vertical dimension of steel longitudinal beam 31), wherein steel longitudinal beam top plate 311 is 400mm wide and 16mm thick; steel longitudinal beam web 312 is 1134mm high and 18mm thick; steel longitudinal beam bottom plate 313 is 600mm wide and 30mm thick. Concrete bridge deck 32 adopts common concrete, and vertical common steel bar and horizontal common steel bar are arranged in concrete bridge deck 32 (specifically as Figure 4 and Figure 5 As shown), the concrete ...

Embodiment 2

[0044] The overall construction method of this implementation example is as follows:

[0045] Firstly manufacture the steel girder segments and transport them to the prefabrication site, complete the splicing of each steel girder 31 on the pedestal, then prefabricate the bridge deck on the top of the two steel longitudinal girders 31, demould and store after the concrete strength reaches the design strength Then the prefabricated girders are hoisted to the installed bridge deck by the gantry crane in the girder yard, and the beam transport vehicle uses the existing bridge deck to transport the prefabricated beams to the erection position, and the prefabricated composite beams are erected hole by hole through the bridge erecting machine. After the whole bridge is erected, The longitudinal wet joint 4 is poured, and finally the beam at the continuous pier is poured to complete the system conversion from simply supported to continuous.

[0046] The construction method for the π-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com