A preparation method of a photocathode of a streak camera

A stripe camera and photocathode technology, applied in photoemission cathodes, discharge tube main electrodes, X-ray tube electrodes, etc., can solve the problems of undetectable signals, photocathode time resolution reduction, unfavorable high time resolution images, etc. Achieve the effect of wide spectral response range, good transmittance and good time resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

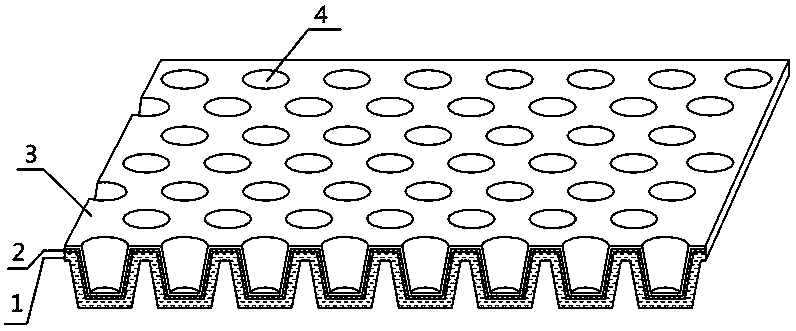

[0038] This embodiment introduces a method for preparing a photocathode of a stripe camera whose response range is between ultraviolet rays and X-rays. see figure 1 , the photocathode uses an organic thin film 1 as a supporting structure, and the organic thin film has micropores 4 arranged in an array in the shape of a rounded truncated cone; the top of the organic thin film 1 is a conductive layer 2, and the material of the conductive layer 2 is conductive metal such as Au, Al or Cu. ; Above the conductive layer 2 is the photoemissive layer 3, the photoemissive layer 3 is Au or alkali halogen compound with high photoelectric conversion efficiency, and the alkali halogen compound includes CsI, CsBr, KI or KBr.

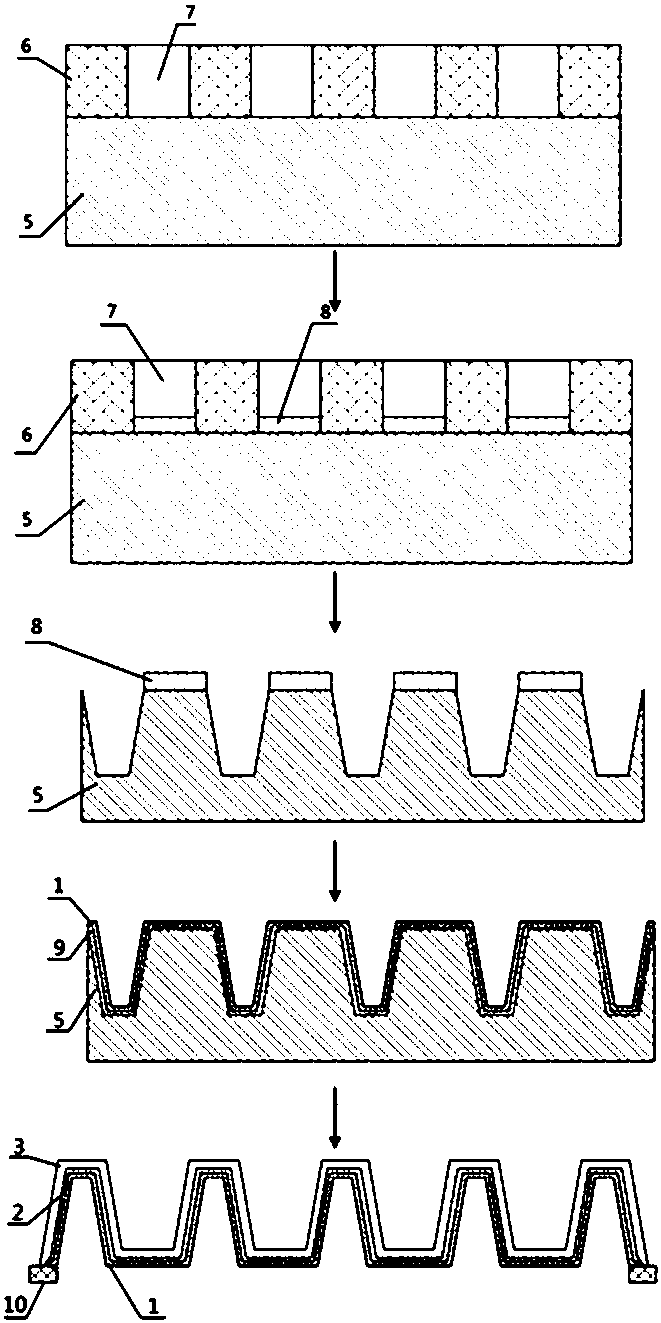

[0039] see figure 2 , the preparation process of this embodiment is as follows:

[0040] Provide a piece of polished silicon wafer 5 and a piece of porous anodized aluminum 6 with through holes 7 of uniform pore size, wash the polished silicon wafer 5 and porous ano...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com