Micro-powder encapsulating and material mixing device for improving content uniformity of clonidine hydrochloride in zhenju antihypertensive tablets and material mixing method

A technology of clonidine hydrochloride and Zhenju Jiangya tablets, which is applied in the field of biomedicine, can solve problems such as poor process stability, secondary environmental pollution, and complex production processes, and achieve the goal of improving content uniformity, reducing workload, and reducing errors Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

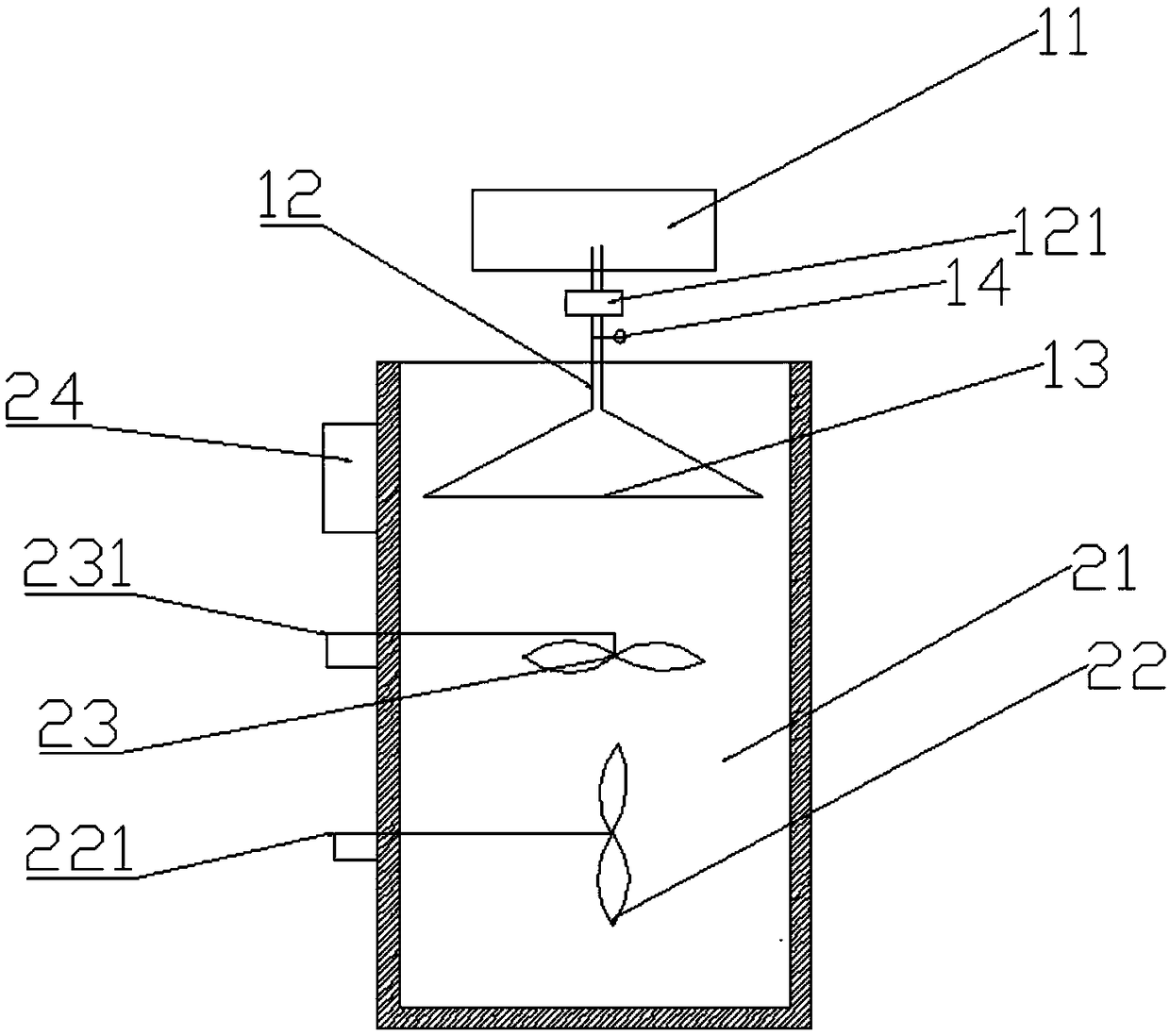

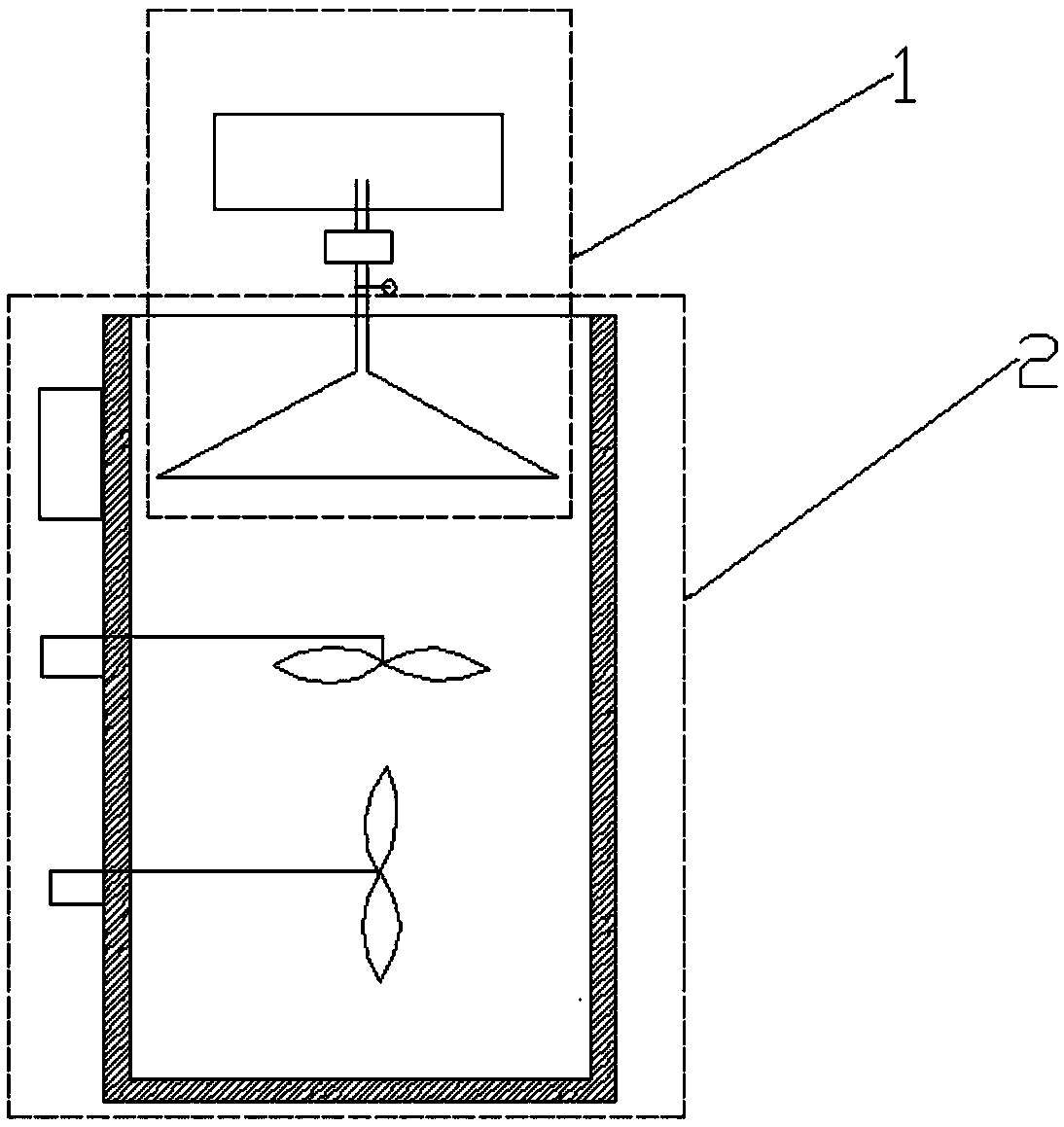

[0031] Please refer to Figure 1-Figure 2 As shown, a micropowder encapsulation mixing device for improving the content uniformity of clonidine hydrochloride in Zhenju Jiangya Tablets, including a drug dosing unit 1 and a drug mixing unit 2 located directly below the drug adding unit 1;

[0032] The dosing unit 1 includes a dosing container 11 and a dosing pipeline 12; the dosing pipeline 12 extends from the bottom of the dosing container 11 to the inner top of the mixing unit 2; the end of the dosing pipeline 12 is provided with a dosing nozzle 13;

[0033] The drug mixing unit 2 includes a drug mixing container 21, a first stirring device 23 and a second stirring device 22 arranged vertically from top to bottom, and a PLC central control center 24 arranged on the side wall of the drug mixing container 21; The first stirring device 23 extends to the outer wall of the mixing container 21 and is connected with a first stirring motor 231; the second stirring device 22 extends t...

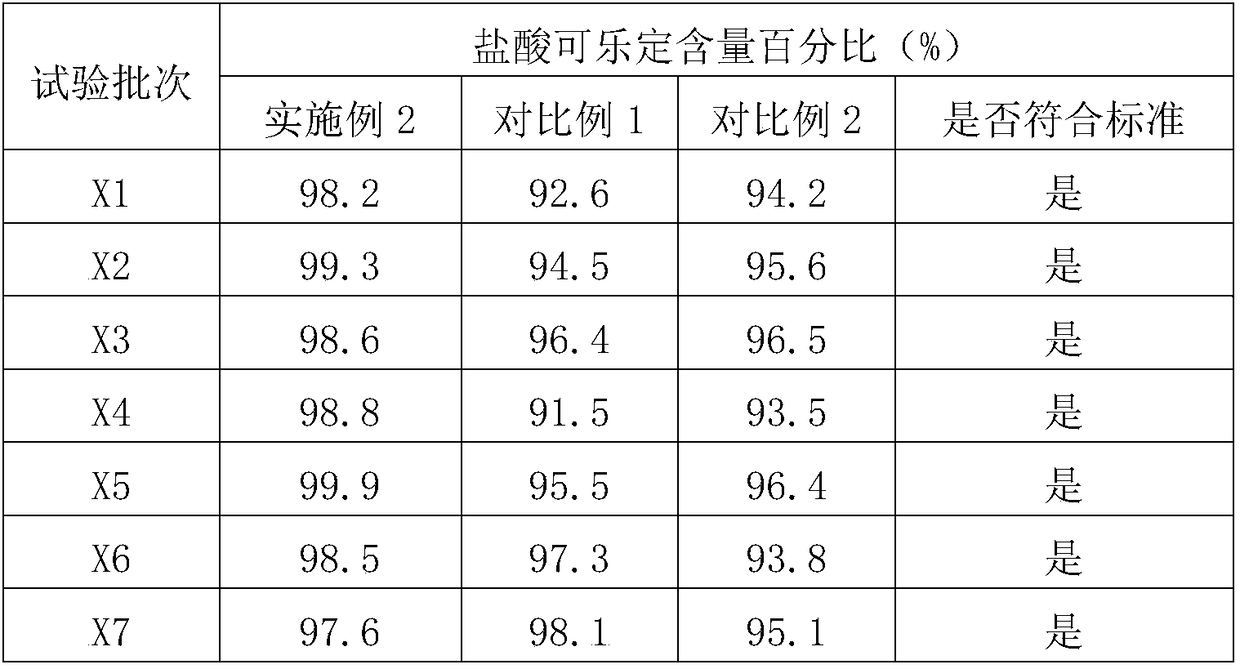

Embodiment 2

[0042] The micropowder encapsulation and mixing device is the same as in Example 1.

[0043] According to the prescription formula ratio of Zhenju Jiangya Tablets in the "International Drug Standards of the State Food and Drug Administration"; use the above-mentioned mixing method of a micropowder encapsulation mixing device that improves the content uniformity of clonidine hydrochloride in Zhenju Jiangya Tablets , including the following steps:

[0044] 1) get clonidine hydrochloride 0.03g and be dissolved in the ethanol solution of 30g 93%, prepare the clonidine hydrochloride solution that dissolves completely;

[0045] 2) Place the completely dissolved clonidine hydrochloride solution in the dosing container 11;

[0046] 3) Add the required amount of Zhenju Jiangya Tablets to the mixing container 21 to prepare raw materials other than clonidine hydrochloride: wild chrysanthemum flower cream powder: 100g; pearl layer powder: 100g; clonidine hydrochloride: 0.03g; Hydrochlor...

Embodiment 3

[0050] The micropowder encapsulation and mixing device is the same as in Example 1.

[0051] According to the prescription formula ratio of Zhenju Jiangya Tablets in the "International Drug Standards of the State Food and Drug Administration"; use the above-mentioned mixing method of a micropowder encapsulation mixing device that improves the content uniformity of clonidine hydrochloride in Zhenju Jiangya Tablets , including the following steps:

[0052] 1) get clonidine hydrochloride 0.03g and be dissolved in the ethanol solution of 30g 95%, prepare the clonidine hydrochloride solution that dissolves completely;

[0053] 2) Place the completely dissolved clonidine hydrochloride solution in the dosing container 11;

[0054] 3) Add the required amount of Zhenju Jiangya Tablets to the mixing container 21 to prepare raw materials other than clonidine hydrochloride: wild chrysanthemum flower cream powder: 100g; pearl layer powder: 100g; clonidine hydrochloride: 0.03g; Hydrochlor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com