Nail shooting bullet for arc nail shooting gun and preparation method of nail shooting bullet as well as arc nail shooting gun

A technology for shooting nail bullets and nail guns, which is applied in nailing tools, manufacturing tools, alkali metal compositions, etc., can solve problems such as not being environmentally friendly enough, and achieve the effects of easy-to-obtain formula, simple formula and high safety performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A nail bullet for an arc nail gun, comprising the following components:

[0047] Potassium perchlorate 1 part

[0048] Starch as a burning agent 0.1 parts

[0049] 0.1 part of water.

[0050] The total weight of the above-mentioned nail shooting bullet is 0.504g, and its preparation process is 1) pulverizing 0.420g of potassium perchlorate, passing through a 150-mesh sieve, adding 0.042g of water and mixing evenly, then adding 0.042g of starch, stirring and mixing evenly After that, it is immediately filled into the cartridge 72, and vacuum-packed to evaporate moisture.

[0051] Or prepare a nail-shooting projectile with a large total mass at the ratio of 1 part of potassium perchlorate, 0.1 part of starch, and 0.1 part of water, and then take 0.504 g and fill it into the cartridge 72 for vacuum packaging.

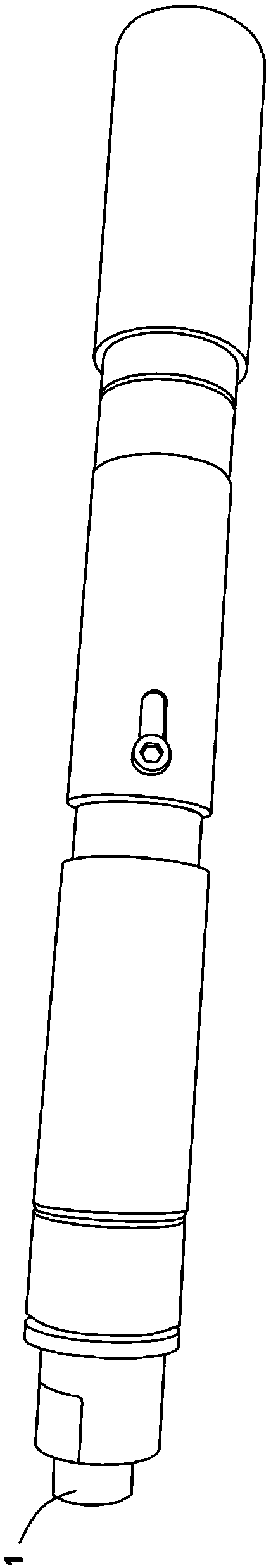

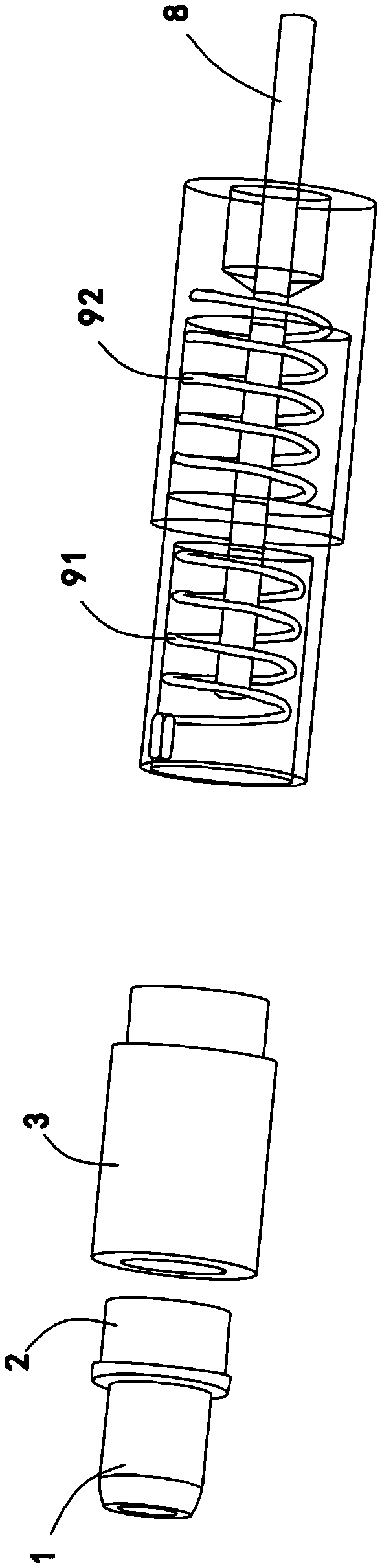

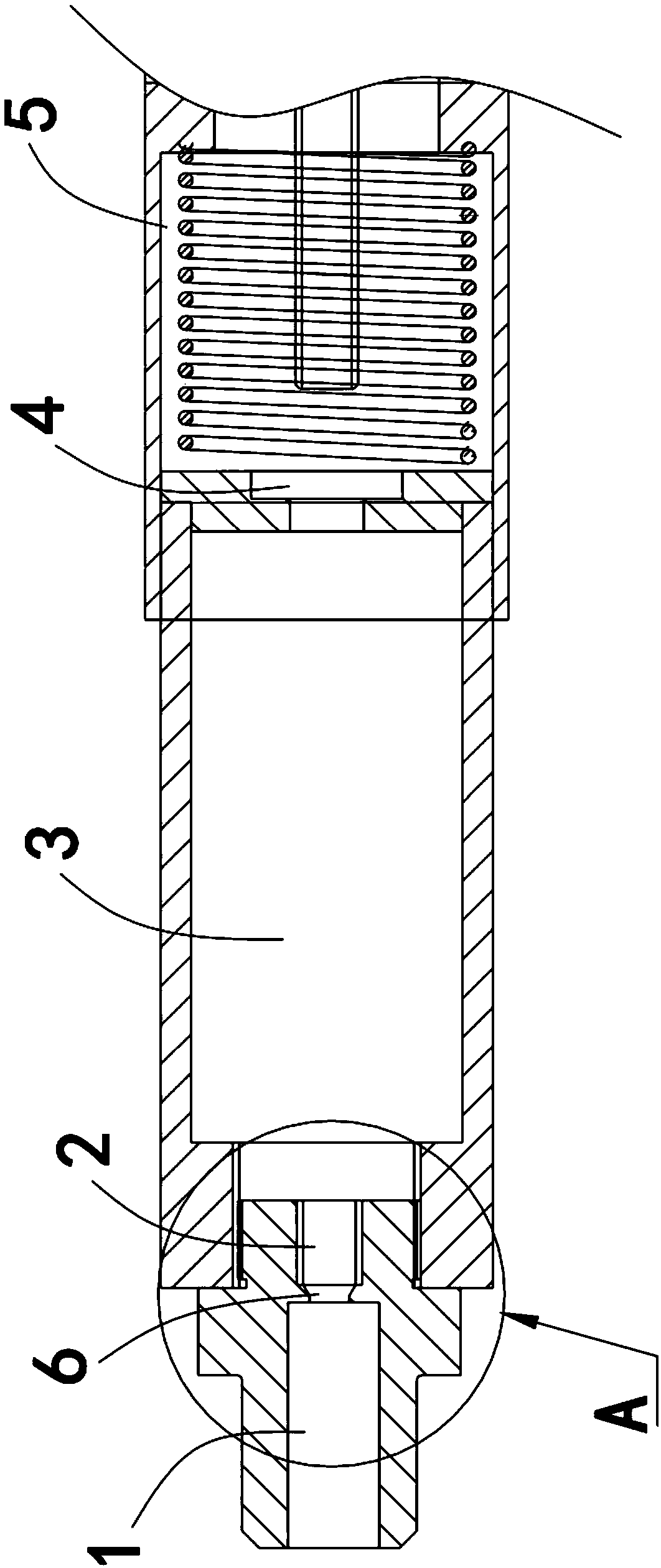

[0052] Such as Figure 1-7 As shown, the arc nail gun is sequentially provided with a first cavity 1, a second cavity 2, a third cavity 3, a fourth cavity 4 and...

Embodiment 2

[0056] A nail bullet for an arc nail gun, comprising the following components:

[0057] Potassium chlorate 1 part

[0058] 0.2 parts of starch as a burning agent

[0059] 0.3 parts of water.

[0060] The total weight of the above-mentioned nail shooting bullet is 0.78g, and its preparation process is 1) pulverizing 0.520g of potassium chlorate, passing through a 140-mesh sieve, adding 0.104g of water and stirring to mix evenly, then adding 0.156g of starch, stirring and mixing evenly , immediately filled into the cartridge 72, and vacuum-packed to prevent moisture from evaporating.

[0061] Or prepare a nail-shooting projectile with a large total mass at the ratio of 1 part of potassium chlorate, 0.2 part of starch, and 0.3 part of water, and then take 0.78 g and fill it into the cartridge 72 for vacuum packaging.

[0062] The structures of the arc nail gun and the nail shooting are the same as those in the first embodiment, and will not be repeated here.

Embodiment 3

[0064] A nail bullet for an arc nail gun, comprising the following components:

[0065] Potassium perchlorate 1 part

[0066] Starch as a burning agent 0.37 parts

[0067] Water 0.274 parts.

[0068] The total weight of the above-mentioned nail shooting bullet is 1.2g, and its preparation process is 1) pulverize 0.73g of potassium perchlorate, pass through a 160-mesh sieve, add 0.2g of water and stir to mix evenly, then add 0.27g of starch, stir and mix evenly After that, it is immediately filled into the cartridge 72, and vacuum-packed to evaporate moisture.

[0069] Or prepare a nail-shooting projectile with a larger total mass at the ratio of 1 part of potassium perchlorate, 0.37 part of starch, and 0.274 part of water, and then take 1.2 g and fill it into the cartridge 72 for vacuum packaging.

[0070] The structures of the arc nail gun and the nail shooting are the same as those in the first embodiment, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com