Coal gasification supercritical carbon dioxide electricity generating system and method

A carbon dioxide, power generation system technology, applied in the directions of jet propulsion, gas turbine, machine/engine, etc., can solve the problems of limitation and the efficiency of generator sets cannot be improved, achieve high economy, improve heat-power conversion efficiency, resource The effect of rational use

Pending Publication Date: 2018-12-28

HUANENG CLEAN ENERGY RES INST

View PDF4 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The purpose of the present invention is to provide a coal gasification supercritical carbon dioxide power generation system and method, which solves the existing defect that the efficiency of the generator set cannot be improved due to the limitation of the initial parameters of the working fluid by the material

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

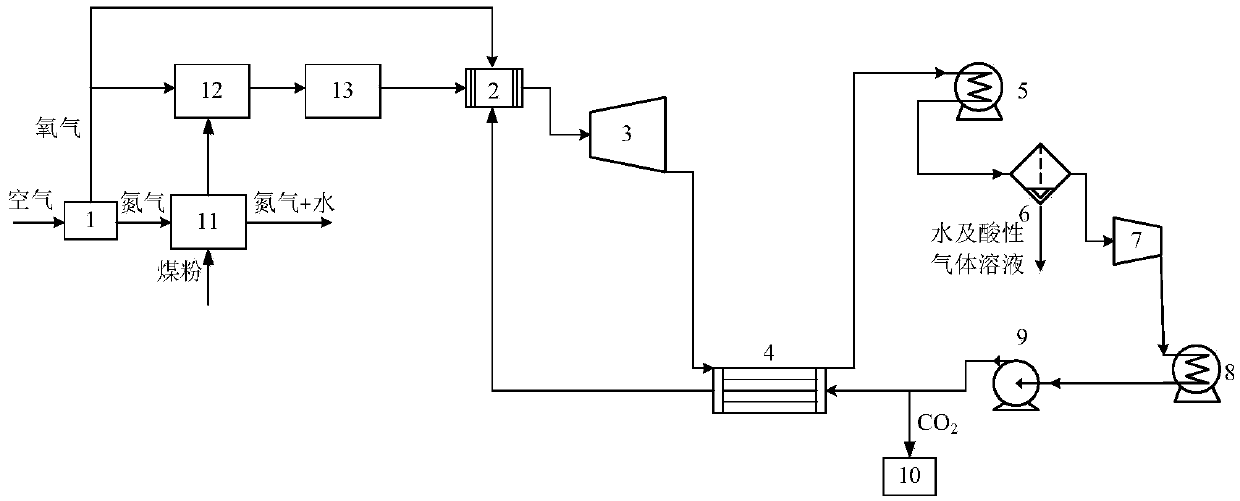

The invention provides a coal gasification supercritical carbon dioxide electricity generating system and method. The coal gasification supercritical carbon dioxide electricity generating system comprises an air separating device, a combustor, a turbine and a gas cycling system, wherein an oxygen outlet of the air separating device is connected with an oxygen inlet of the combustor; a coal gas pipeline is also connected to the combustor; a carbon dioxide outlet of the combustor is connected with a gas inlet of the turbine; and an exhaust outlet of the turbine enters the combustor again throughthe gas cycling system. According to the coal gasification supercritical carbon dioxide electricity generating system adopting the structure, disclosed by the invention, the conversion efficiency ofheat into power can be greatly improved, the size of the equipment is reduced, and the coal gasification supercritical carbon dioxide electricity generating system is economical.

Description

technical field The invention belongs to the technical field of supercritical carbon dioxide power generation, and in particular relates to a coal gasification supercritical carbon dioxide power generation system and method. Background technique Energy and the environment are two major problems facing the development of human society. Continuously improving the efficiency of generator sets is the eternal theme and goal of power industry research. Currently, the more commonly used power cycles include the Rankine cycle with water as the working fluid and the Brayton cycle with air as the working fluid. Conventional coal-fired power plants mainly use the Rankine cycle with water as the working fluid. At present, the initial steam parameters of the largest one-million-kilowatt coal-fired power plant have reached 31MPa and 620°C. The gas turbine mainly uses the Brayton cycle with air as the working medium. At present, the inlet gas temperature of the advanced aero-engine turbin...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F02C3/28F02C7/32

CPCF02C3/28F02C7/32

Inventor 彭烁周贤李启明钟迪王保民

Owner HUANENG CLEAN ENERGY RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com