Automatic hydraulic generating speed bump device

A technology of hydraulic power generation and speed bumps, applied in the direction of machines/engines, mechanisms that generate mechanical power, roads, etc., can solve problems such as large energy waste, and achieve the effects of stable power generation process, strong reliability and high energy recovery efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

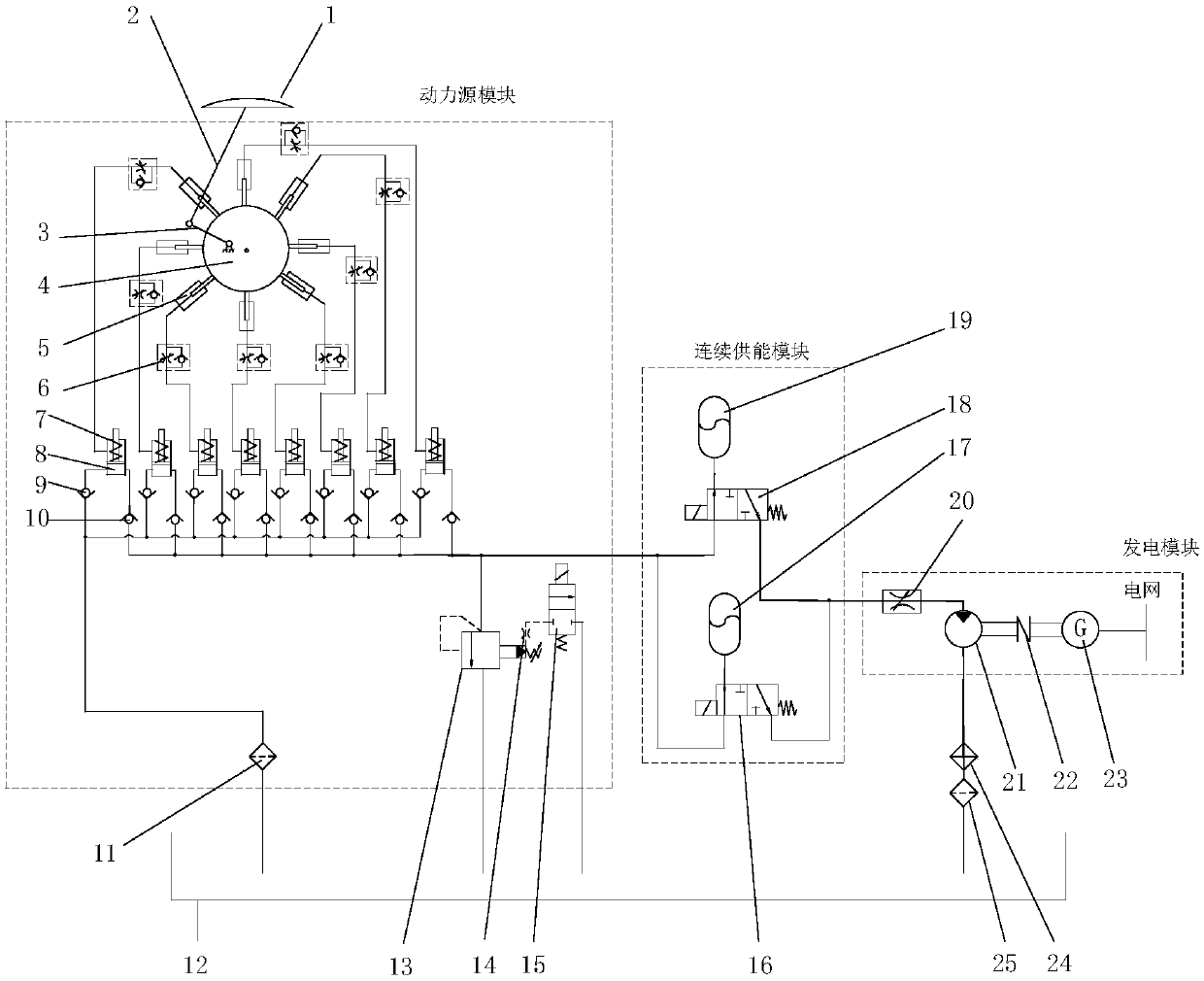

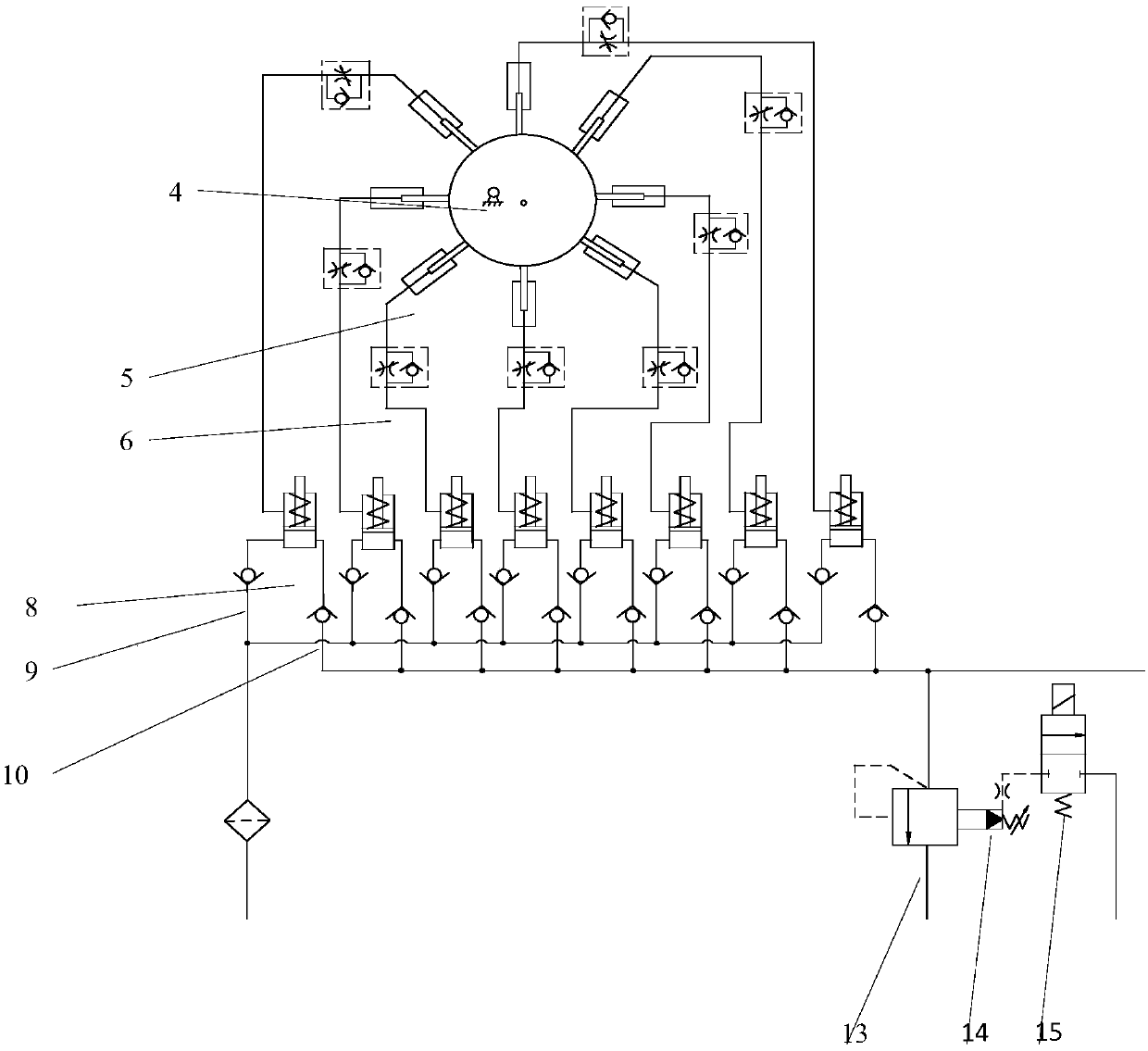

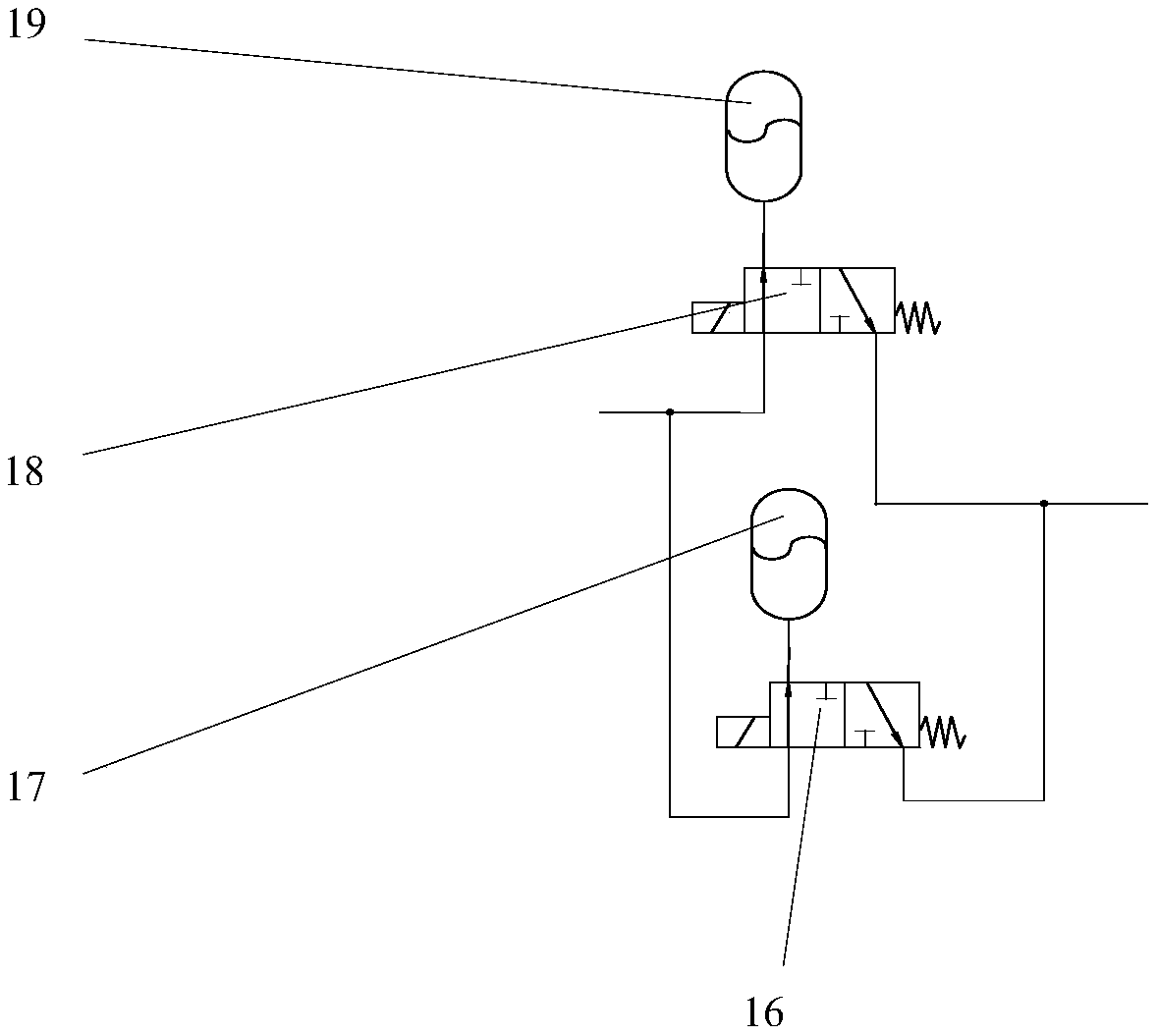

[0022] The hydraulic power generation speed reduction belt device of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0023] figure 1 A schematic diagram of the principle of the hydraulic power generation speed reduction belt device according to the present invention is shown. The hydraulic power generation deceleration belt device of the present invention adopts a modular installation method, which specifically includes the following modules: a pulse type power source module, a continuous energy supply module and a power generation module.

[0024] Such as figure 1 As shown, the hydraulic power generation deceleration belt device according to the present invention can specifically include a deceleration belt 1, a connecting rod 2, a connecting rod 3, a cam 4, a plunger cylinder 5, a one-way throttle valve 6, a spring 7, a piston cylinder 8, a single Directional valve 9, one-way valve 10, filter 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com