Vibration fatigue test device and method in high-pressure hydrogen environment

A vibration fatigue and testing device technology, applied in vibration testing, measuring devices, testing of machine/structural components, etc., can solve the problem of "big gap between the environment and vibration fatigue characteristics without considering", and ensure the safety of equipment and personnel. The results are reliable and the effect of the experimental operation is perfect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

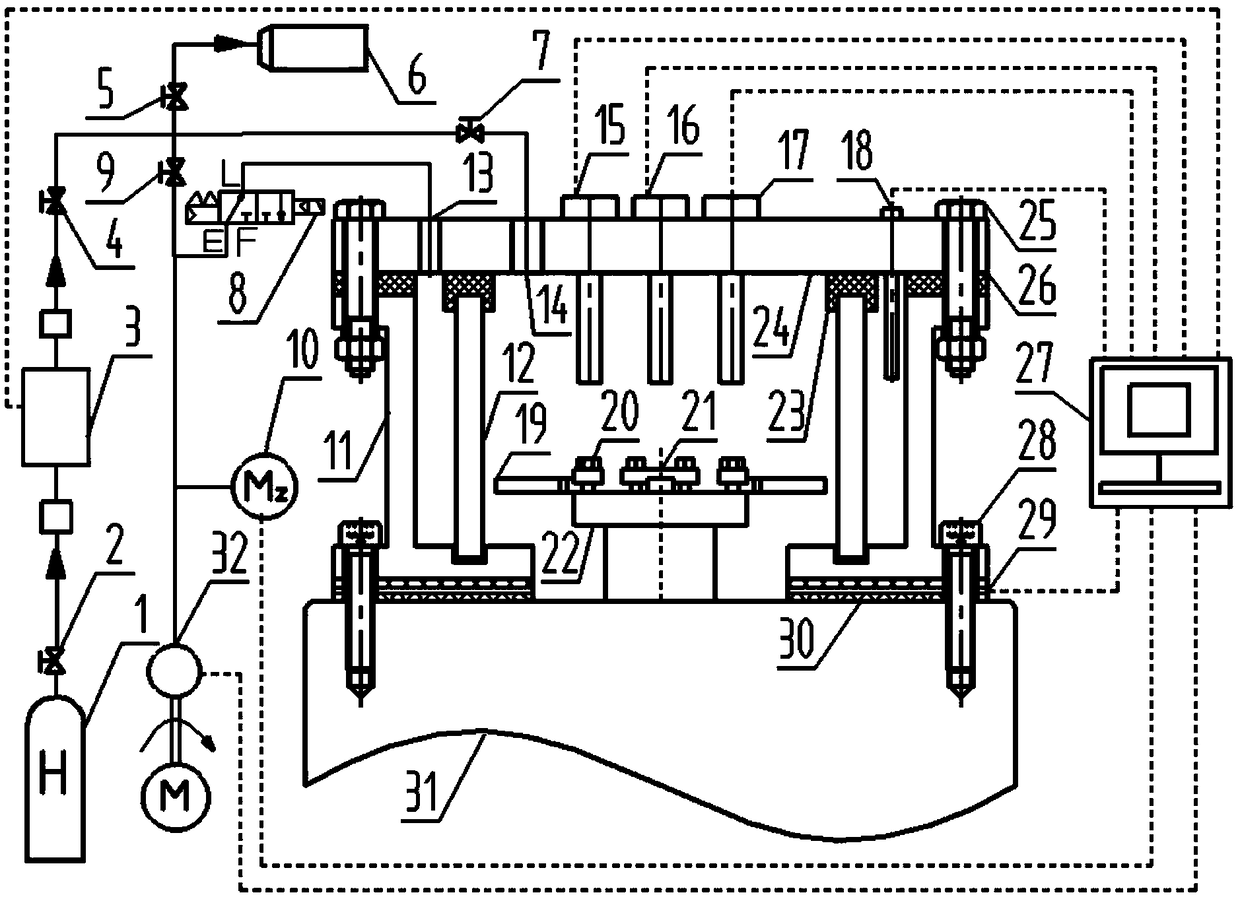

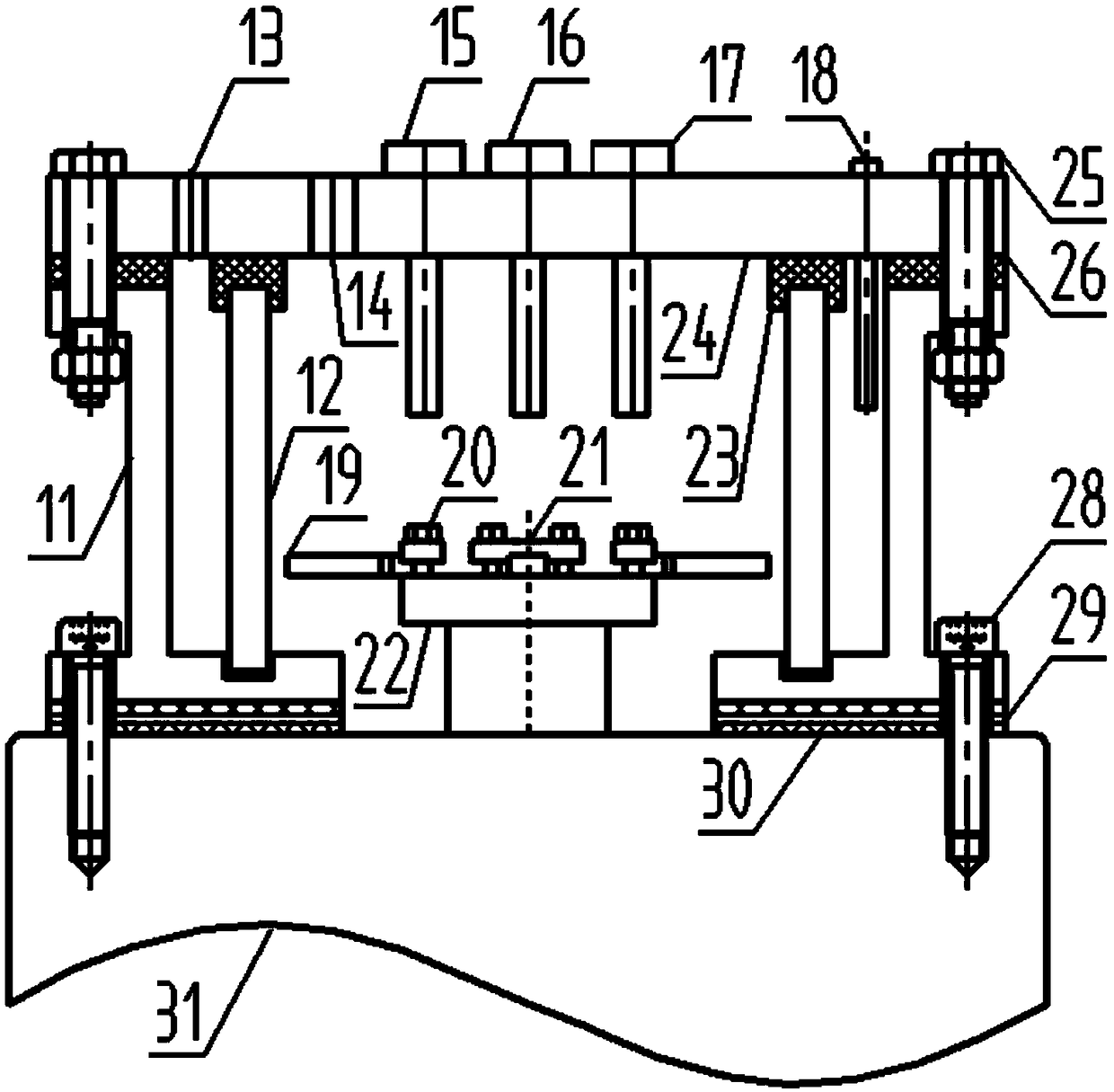

[0038] Such as figure 1 with figure 2 As shown, the vibration fatigue testing device under the high-pressure hydrogen environment of the present invention includes a vibration table 22, a closed box, a hydrogen system and an industrial computer 27; the vibration table 22 is placed in a closed box, and the hydrogen The system is used to fill the closed box with hydrogen gas; the vibration sample 19 is fixed on the vibration table 22, and the industrial computer 27 controls the vibration table 22 and the hydrogen system.

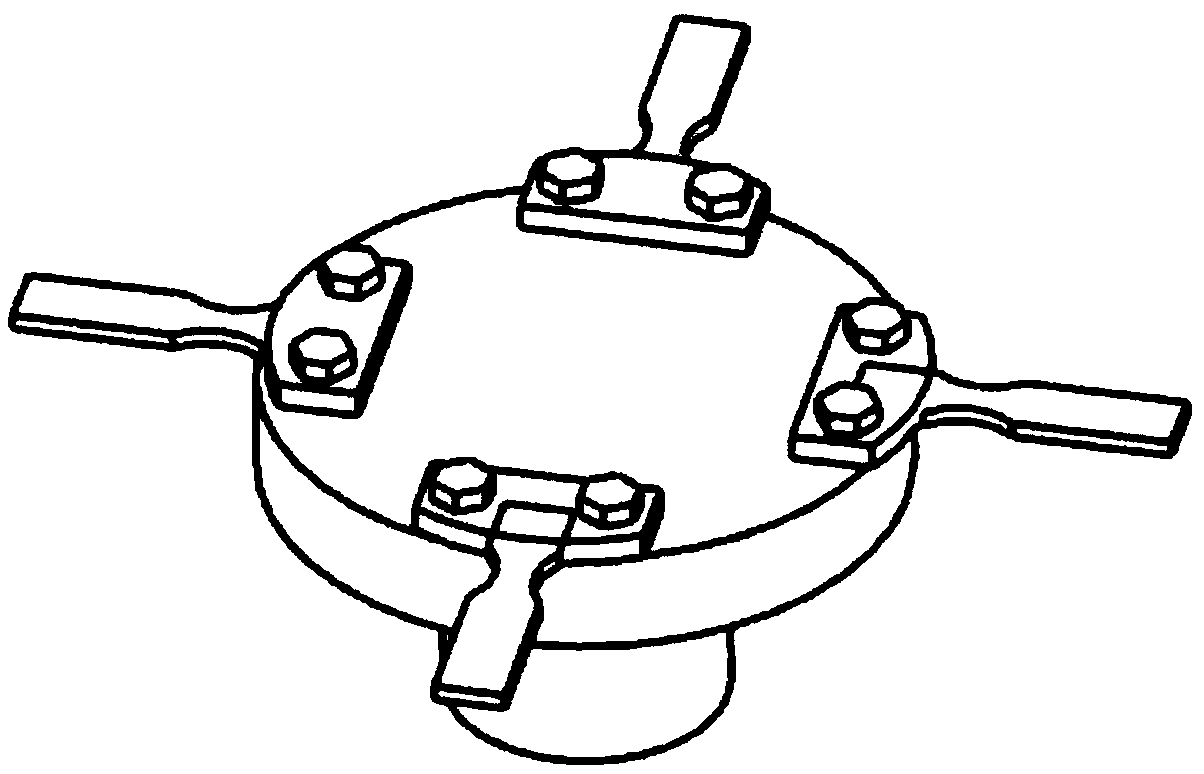

[0039] Described closed box comprises vibrating table base 31, upper top cover 24, inner side wall 12 and outer side wall 11, is provided with outer side wall 11 between described vibrating table base 31 and upper top cover 24, and described vibrating t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com