Dental implant system

A technology of dental implants and implants, which is applied in dentistry, dental implants, dental restorations, etc., can solve the problems of large cutting resistance, stress concentration, deformation, etc., and achieve the effect of improving life expectancy, reliability, and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0110] In this embodiment, metal titanium and titanium alloy are used as materials, which have good biocompatibility and mechanical processing performance. By performing sandblasting, acid etching and plasma oxidation treatment processes on the surface of titanium materials, the biological properties of implants can be effectively improved. Active, enhance the osseointegration performance of the implant.

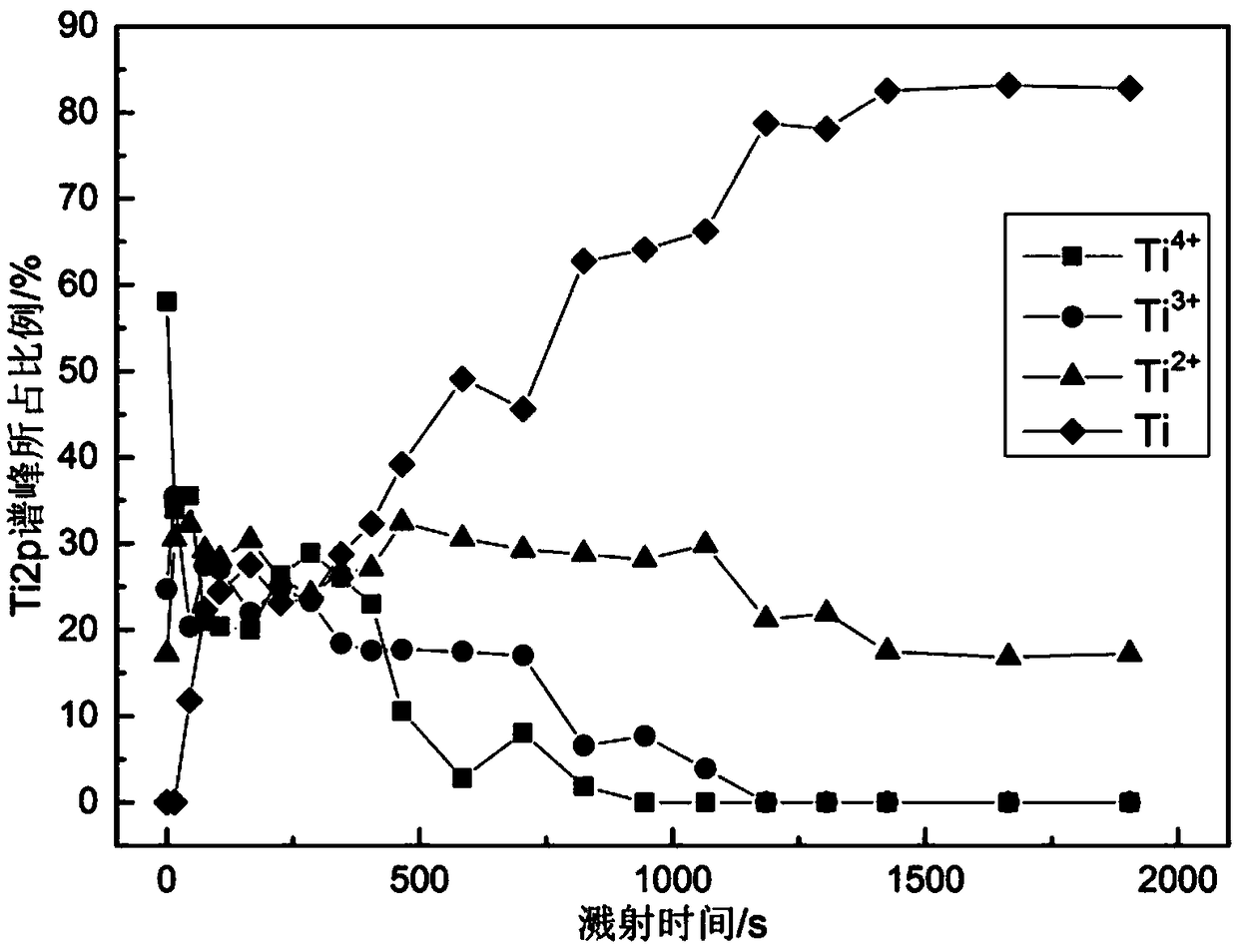

[0111] The surface of the implant is treated by sand blasting acid etching + plasma oxidation, such as figure 1 As shown, a titanium oxide layer structure with different valence states coexisting with gradient composition is prepared. Such as figure 1 As shown, the surface morphology of the prepared implant is an irregular porous oxide layer structure, and the micropores are closely arranged, which is conducive to the attachment of bone cells, suitable for the growth of alveolar bone, and can enhance the speed and quality of osseointegration. Among them, the O of the impla...

Embodiment 2

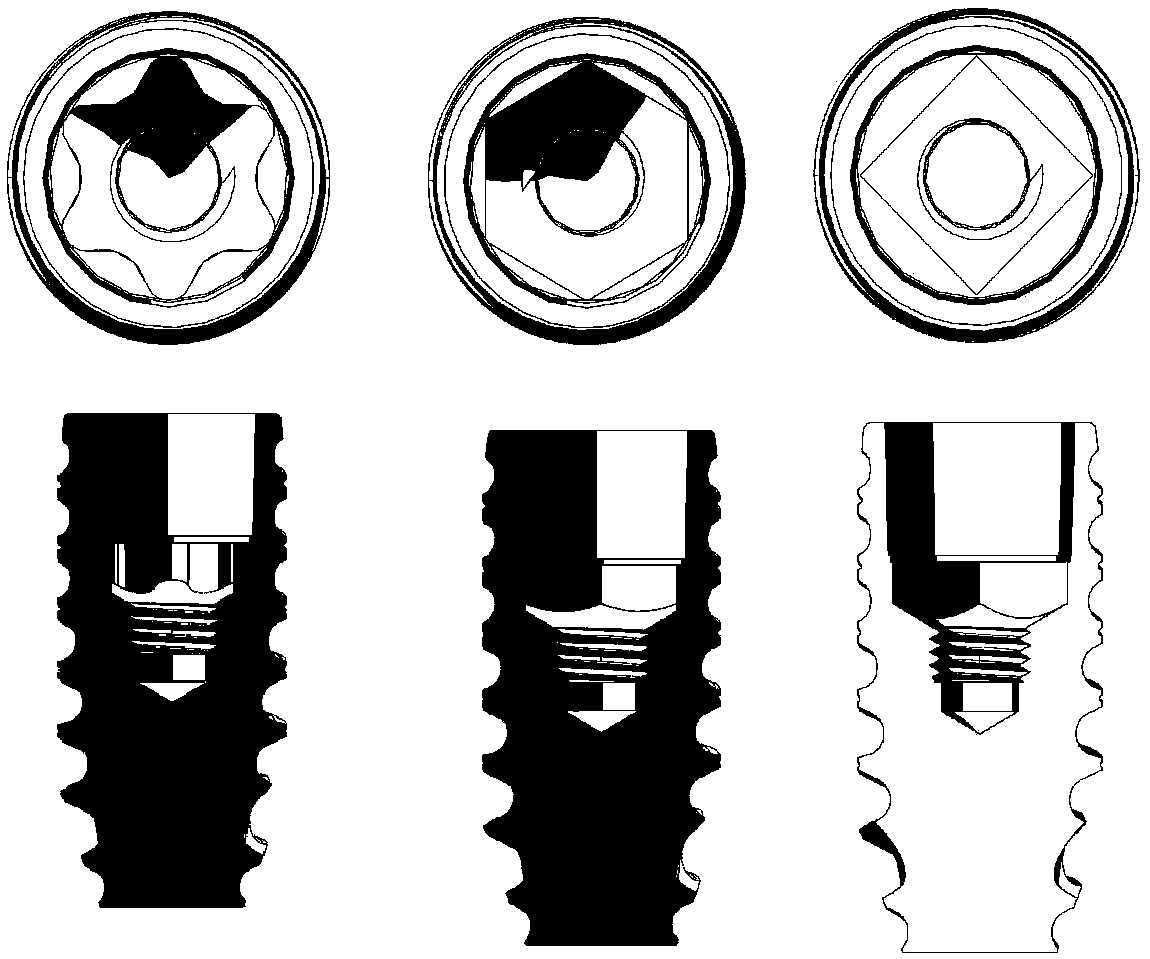

[0113] As shown in Figures 8 to 13, the dental implant system is composed of a straight abutment 1, a connecting screw 2 and an implant 3; the outer surface of the implant 3 is composed of two kinds of threads from top to bottom, and the whole body is made of the first The main thread 1-2 and the first thread 1-3 are combined to form a double thread; the outer head of the implant 3 is processed with a double leaf-shaped first self-tapping groove 1-7, and the top of the first implant head 1-8 It is a horizontal end face; and the implant is provided with a first tapered hole 1-1 with a taper of 3°, followed by a first Torx structure 1-4 at the lower part, and finally a first internal threaded hole 1-5. (See Figure 8 , Figure 9 , Figure 10 , Figure 11A , Figure 12 , Figure 13 )

[0114] Such as Figure 11A As shown, the internal structure of the implant body is set as a first tapered hole 1-1 with a taper of 3°, which is used in conjunction with the first Torx struct...

Embodiment 3

[0119]As shown in Figures 8 to 13, the dental implant system is composed of a straight abutment 1, a connecting screw 2 and an implant 3; the outer surface of the implant 3 is composed of two kinds of threads from top to bottom, and the whole body is made of the first The main thread 1-2 and the first thread 1-3 are combined to form a double thread; the outer head of the implant 3 is processed with a double leaf-shaped first self-tapping groove 1-7, and the top of the first implant head 1-8 and a first tapered hole 1-1 with a taper of 3° is provided inside the implant, followed by a Torx structure 1-4 at the lower part, and finally a first internal threaded hole 1-5.

[0120] The outside of the straight abutment 1 is composed of the first crown connecting section 1-12, the first gingival piercing section and the implant insertion section 1-13; The gingival segment and the implant insertion segment 1-13, the second Torx structure 1-14 cooperate with the first tapered hole 1-1 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum stress | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com