Fiber shrinkage-reducing and anti-cracking agent and preparation method thereof

An anti-crack agent and fiber technology, which is applied in the field of fiber shrinkage-reducing and anti-crack agent and its preparation, can solve the problems such as discount of anti-crack effect, poor stability, and inability to uniformly disperse fibers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

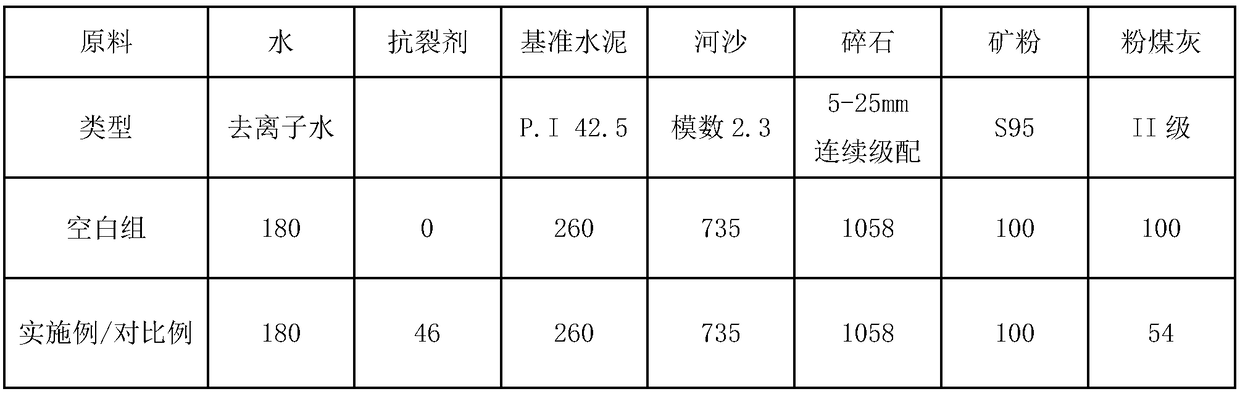

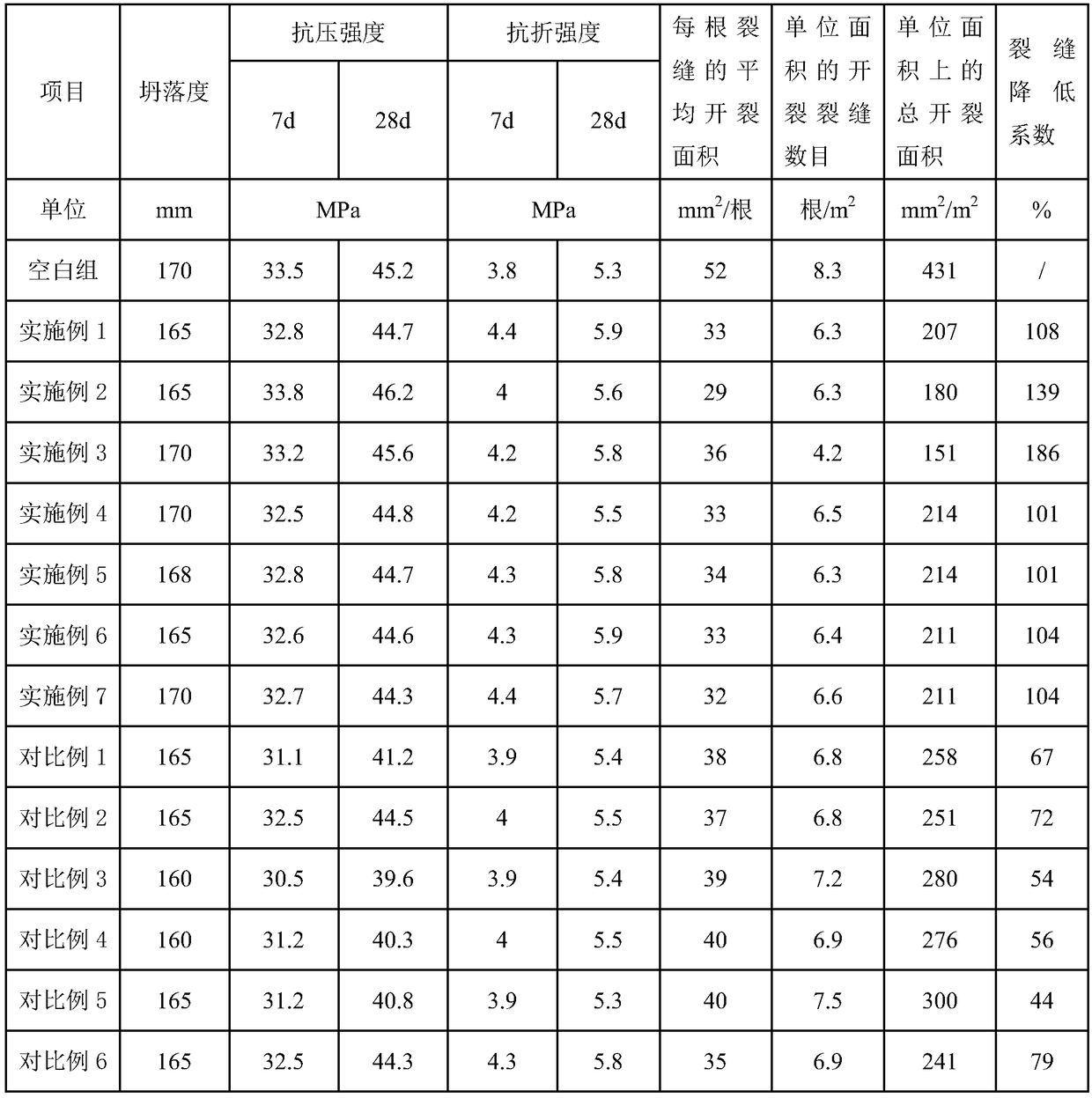

Examples

Embodiment 1

[0024] The fiber shrinkage and anti-cracking agent of the present embodiment is weighed according to the following proportioning ratio in terms of mass percentage:

[0025]Microporous fibers 2.5%, polypropylene fibers. The diameter of the microporous fiber is 60 μm, the diameter of the solid body part of the middle fiber is 40 μm, and the thickness of the outer microporous part is 20 μm. 120, the pores are not connected to each other;

[0026] The shrinkage reduction component is 0.8%, which is formed by mixing methyl vinyl ether-maleic anhydride copolymer and polyether polyol according to the mass ratio of 1:1.5;

[0027] Alum stone powder 45%, Al of alum stone powder 2 o 3 The content is 30%, the specific surface area is 400m 2 / kg, 1.18mm sieve residue is 0%;

[0028] 20% coal gangue powder, which is ground from spontaneous combustion coal gangue, with a specific surface area of 600m 2 / kg, the activity index was 80% in 28 days.

[0029] Gypsum 31.7%, is desulfuriz...

Embodiment 2

[0032] The fiber shrinkage and anti-cracking agent of the present embodiment is weighed according to the following proportioning ratio in terms of mass percentage:

[0033] Microporous fibers 1.5%, are polyester fibers. The diameter of the microporous fiber is 50 μm, the diameter of the solid body part of the middle fiber is 30 μm, and the thickness of the outer microporous part is 20 μm. 180, the pores are not connected to each other;

[0034] The shrinkage reduction component is 1%, which is formed by mixing methyl vinyl ether-maleic anhydride copolymer and polyether polyol according to the mass ratio of 1:2;

[0035] Alum stone powder 35%, Al of alum stone powder 2 o 3 The content is 35%, the specific surface area is 300m 2 / kg, 1.18mm sieve residue is 0~0.2%;

[0036] 25% coal gangue powder, which is ground from spontaneous combustion coal gangue, with a specific surface area of 500m 2 / kg, the activity index was 65% in 28 days.

[0037] Gypsum 37.5%, is dihydrate...

Embodiment 3

[0040] The fiber shrinkage and anti-cracking agent of the present embodiment is weighed according to the following proportioning ratio in terms of mass percentage:

[0041] Microporous fiber 1%, is polyester fiber. The diameter of the microporous fiber is 80 μm, the diameter of the solid body part of the middle fiber is 60 μm, and the thickness of the outer microporous part is 20 μm. 200, the pores are not connected to each other;

[0042] The shrinkage reduction component is 1%, which is a mixture of methyl vinyl ether-maleic anhydride copolymer and polyether polyol according to the mass ratio of 1:1.5-2.5;

[0043] Alum stone powder 30%, Al of alum stone powder 2 o 3 The content is 40%, the specific surface area is 200m 2 / kg, 1.18mm sieve residue is 0.5%;

[0044] Coal gangue powder 28%, ground from spontaneous combustion coal gangue, specific surface area 400m 2 / kg, the activity index was 50% in 28 days.

[0045] 40% gypsum is natural anhydrite. The purity of gyps...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com