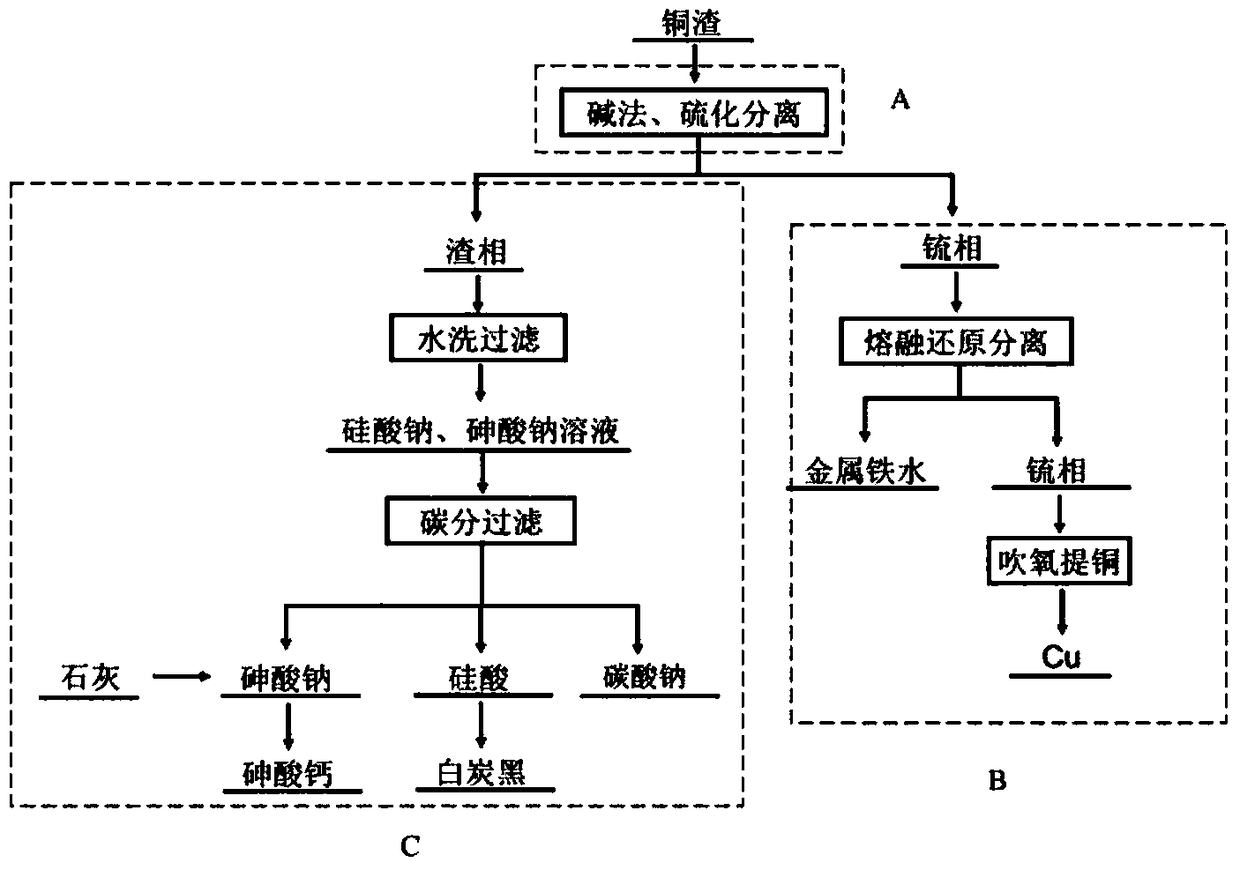

Method for preparing metal iron from copper slag

A technology of metallic iron and copper slag, which is applied in the field of preparing metallic iron from copper slag, can solve the problems of unsatisfactory use requirements, high content of Cu, S and As, etc., and achieve the effects of improving utilization rate, reducing activity, and improving economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Copper slag and FeS, Na 2 CO 3 Mix evenly, the ratio of the amount of FeS added to the mass of copper slag is 0.4, 0.6, 0.8, 1 respectively, and the ratio of the amount of sodium carbonate added to the mass of copper slag is 1. The mixed material is kept and roasted at 1400°C for 2 hours to separate the two phases of slag and matte (that is, melt). The contents of Cu and O in the sulfonium phase were determined by chemical analysis, and the enrichment rates of FeO and Cu in the sulfonium phase were determined by calculation.

[0054] The experimental results show that when the ratio of the amount of FeS added to the mass of copper slag is 0.4, 0.6, 0.8, and 1, the enrichment rates of Cu in the matte phase are 91%, 95%, 97%, and 98%, respectively, and FeO in The enrichment rates of the matte phase are 78%, 86%, 89%, and 91%, respectively. Therefore, the ratio of the amount of FeS added to the mass of copper slag is preferably 0.6-0.8.

Embodiment 2

[0056] Copper slag and FeS, Na 2 CO 3 Mix evenly, the ratio of the amount of FeS added to the amount of copper slag is 0.8, the ratio of the amount of sodium carbonate added to the mass of copper slag is 0.6, 0.8, 1 hour, 1400 ° C for 2 hours of heat preservation and roasting for slag and matte two-phase separation ( i.e. melting). The enrichment ratios of FeO and Cu in the sulfonium phase were determined by the same method as above.

[0057] The experimental results show that when the mass ratio of sodium carbonate to copper slag is 0.6, 0.8, and 1, the enrichment rate of Cu in the matte phase remains at 95%-97%, which has little effect on the enrichment of Cu in the matte phase ; The enrichment rates of FeO in the sulfonium phase were 81%, 86%, and 89%, respectively. Therefore, increasing the amount of sodium carbonate added was beneficial to the dissolution and enrichment of FeO in the sulfonium phase.

Embodiment 3

[0059] Copper slag and FeS, Na 2 CO 3 Mix evenly, the mass ratio of FeS addition to copper slag is 0.8, and the addition of sodium carbonate to copper slag mass ratio is 1. The mixture was roasted at 1250°C, 1300°C, and 1400°C for 2 hours to separate the two phases of slag and matte (melting). The enrichment ratios of FeO and Cu in the sulfonium phase were determined by the same method as above.

[0060] The experimental results show that when the calcination temperatures are 1250°C, 1300°C, and 1400°C, the enrichment rates of Cu in the sulfonium phase are 72%, 91%, and 97%, respectively; the enrichment rates of FeO in the sulfonium phase are 63%, 74%, 89%. It can be seen that the calcination temperature has a great influence on the dissolution and enrichment of FeO and Cu in the matte phase, and the calcination temperature should be controlled above 1300 °C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com