W-Si-Al-Ti-Zr-Y multi-element lightweight composite resistant to high-temperature oxidation and preparation method thereof

A technology for resisting high temperature oxidation and composite materials, applied in the field of metal composite materials and their preparation, can solve the problems of inability to overcome brittleness, inability to maintain passivation, and large differences in melting point.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] In this embodiment, the high temperature oxidation resistant W-Si-Al-Ti-Zr-Y multi-element lightweight composite material, wherein each component constitutes by mass percentage: WSi 2 40%, Al 15%, Ti 4%, Zr 2%, Y 3%, W 36%.

[0023] (chemical formula is W-9.3Si-15Al-4Ti-2Zr-3Y)

[0024] The original powder particle size is: WSi 2 The particle size of the powder is 5 microns, the particle size of the W powder is 2 microns, the particle size of the Ti powder is 3 microns, the particle size of the Al alloy powder is 3 microns, the particle size of the Y powder is 5 microns, and the particle size of the Zr powder is 5 microns.

[0025] The preparation method of high temperature oxidation resistant W-Si-Al-Ti-Zr-Y composite material in this embodiment comprises the following steps:

[0026] 1. Powder making: W-50wt.% Al pre-alloyed powder is obtained by using inert gas atomization method to make W-50wt.%Al pre-alloyed powder by mass ratio of 15% tungsten powder and mass r...

Embodiment 2

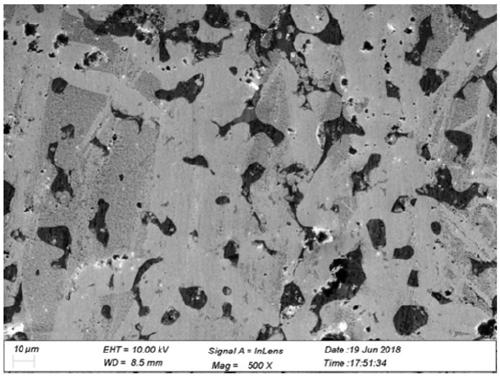

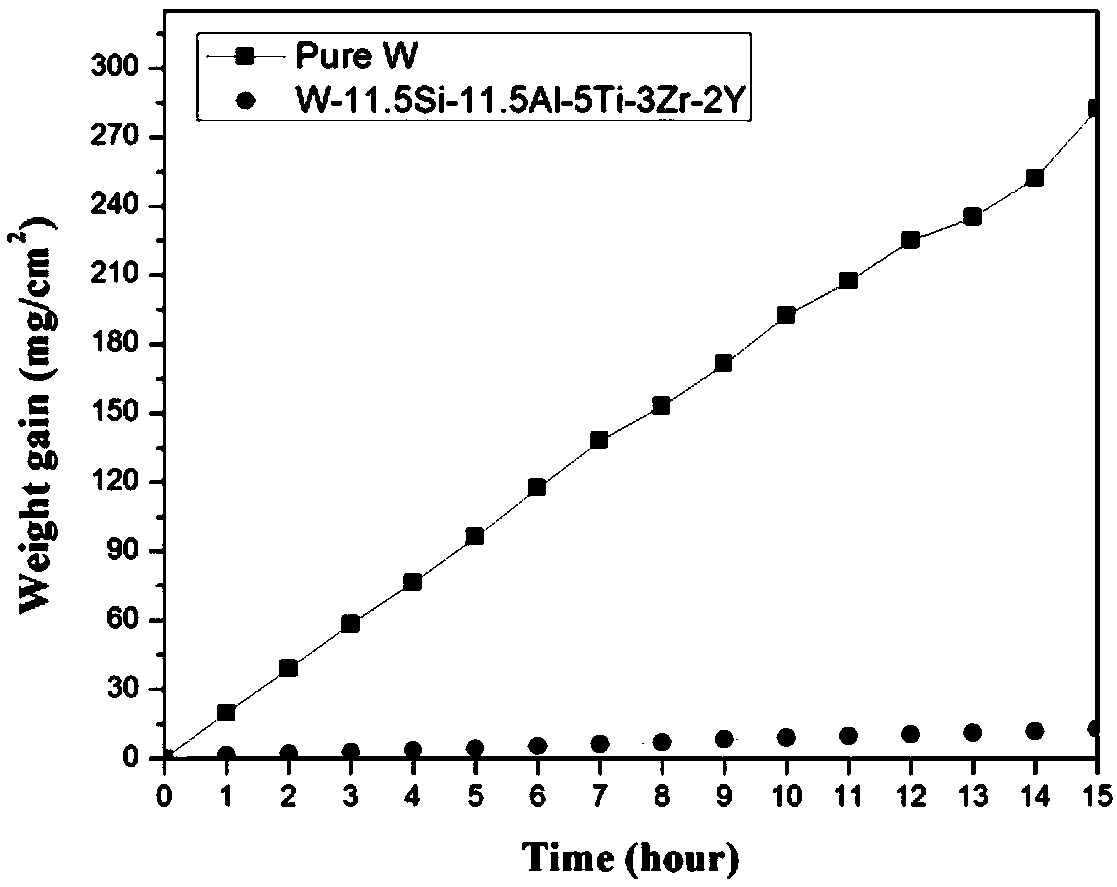

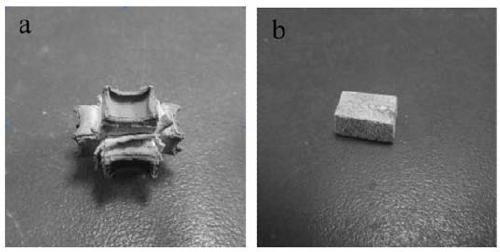

[0030] In this embodiment, the high temperature oxidation resistant W-Si-Al-Ti-Zr-Y multi-element lightweight composite material, wherein each component constitutes by mass percentage: WSi 2 50%, W 28.5%, Al 11.5%, Ti 4%, Zr 4%, Y 2%.

[0031] (Chemical formula is W-11.5Si-11.5Al-4Ti-4Zr-2Y)

[0032] The original powder particle size is: WSi 2 The particle size of the powder is 5 microns, the particle size of the W powder is 2 microns, the particle size of the Ti powder is 3 microns, the particle size of the Al alloy powder is 3 microns, the particle size of the Y powder is 5 microns, and the particle size of the Zr powder is 5 microns.

[0033] In this embodiment, the preparation method of the high-temperature oxidation-resistant W-Si-Al-Ti-Zr-Y multi-element lightweight composite material includes the following steps:

[0034] 1. Powder making: W-50wt.% Al pre-alloyed powder is obtained by using inert gas atomization method to make 11.5% tungsten powder and 11.5% aluminum...

Embodiment 3

[0038] In this embodiment, the high temperature oxidation resistant W-Si-Al-Ti-Zr-Y multi-element lightweight composite material, wherein each component constitutes by mass percentage: WSi2 60%, W 20%, Al 8%, Ti 6%, Zr 5%, Y 1%.

[0039] (chemical formula is W-14Si-8Al-6Ti-5Zr-1Y)

[0040] The original powder particle size is: WSi 2 The particle size of the powder is 5 microns, the particle size of the W powder is 2 microns, the particle size of the Ti powder is 3 microns, the particle size of the Al alloy powder is 3 microns, the particle size of the Y powder is 5 microns, and the particle size of the Zr powder is 5 microns.

[0041] The preparation method of high temperature oxidation resistant W-Si-Al-Ti-Zr-Y composite material in this embodiment comprises the following steps:

[0042] 1. Powder making: W-50wt.% Al pre-alloyed powder is obtained by using an inert gas atomization method to prepare tungsten powder with a mass ratio of 8% and aluminum powder with a mass rati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com