Novel quartz crucible preparation process

A quartz crucible and preparation technology, which is applied in the field of new quartz crucible preparation technology, can solve the problems of reduced crystal formation rate, increased crystal pulling abnormal rate, coating peeling, etc., and achieve the effects of increased service life, stable quality, and reduced reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

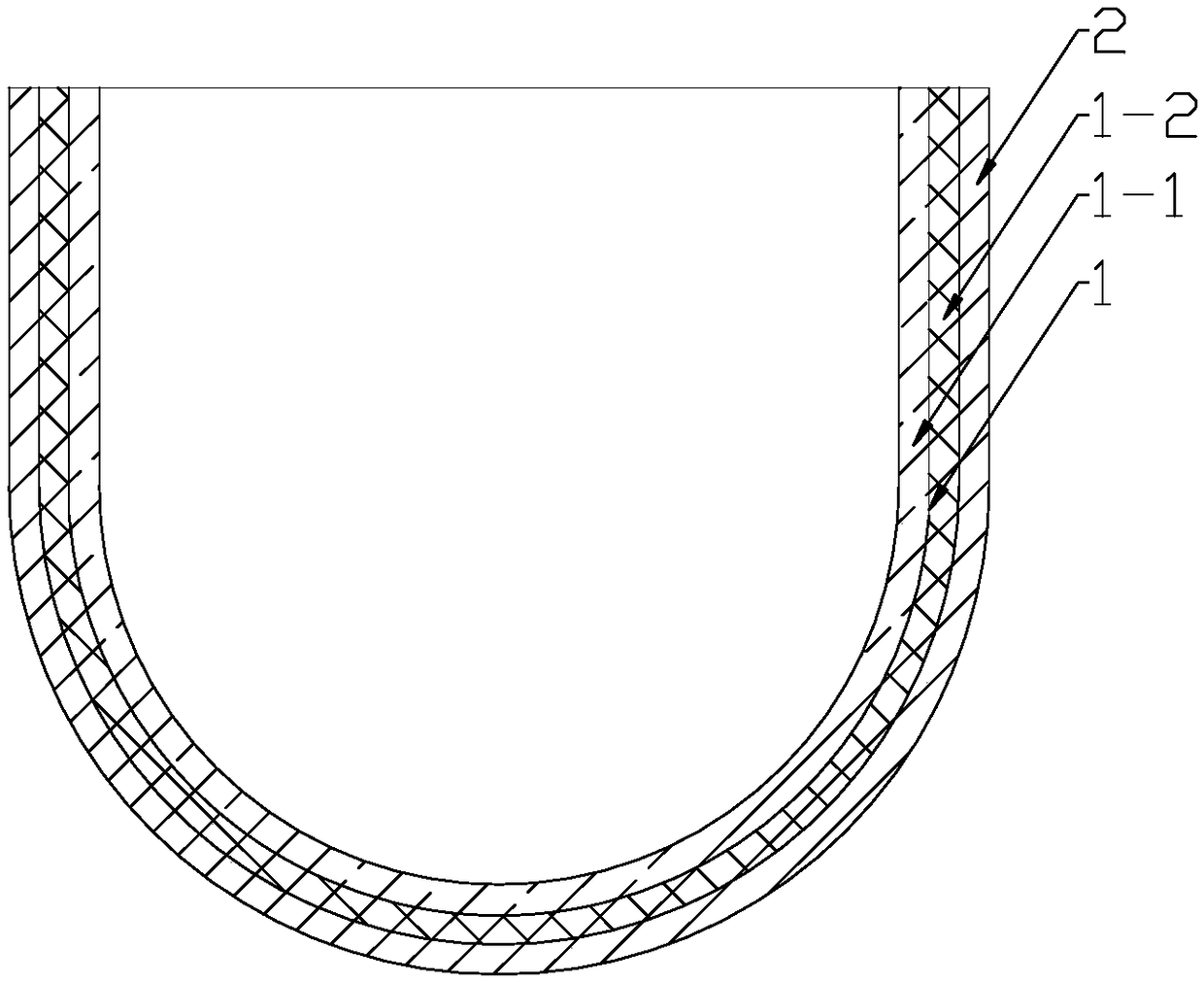

[0022] Such as figure 1 Shown, novel quartz crucible preparation process, the size of the novel quartz crucible of preparation is 20 inches, and it specifically comprises the following steps:

[0023] (1) Raw material preparation: Weigh 20.5kg of quartz sand that has passed the quality inspection and meets the production requirements, the total impurity content of natural quartz sand is ≤20ppm, and the proportion of quartz sand with a particle size of ≤150μm per unit weight is 15%;

[0024] (2) Debugging before prefabrication: (1) After the preparation of raw materials is completed, install the crucible mold and its jacket on the rotating shaft, tilt the crucible mold to the position where the angle between its axis and the horizontal plane is 60°, and then start the rotation Shaft, so that the rotating speed of the crucible mold is 82r / min;

[0025] (3) Prefabrication: (2) After the prefabrication debugging is completed, place the quartz sand in the crucible mold, and use a ...

Embodiment 2

[0034] Such as figure 1Shown, novel quartz crucible preparation process, the size of the novel quartz crucible of preparation is 22 inches, and it comprises the following steps:

[0035] (1) Raw material preparation: Weigh 29.5kg of quartz sand that has passed the quality inspection and meets the production requirements. The total impurity content of natural quartz sand is ≤20ppm, and the proportion of quartz sand with a particle size of ≤150μm per unit weight is 15%;

[0036] (2) Debugging before prefabrication: (1) After the preparation of raw materials is completed, install the crucible mold and its jacket on the rotating shaft, tilt the crucible mold to the position where the angle between its axis and the horizontal plane is 72°, and then start the rotation Shaft, so that the rotating speed of the crucible mold is 80r / min;

[0037] (3) Prefabrication: (2) After prefabrication debugging is completed, place the quartz sand in the crucible mold, and use a forming rod that m...

Embodiment 3

[0046] Such as figure 1 Shown, novel quartz crucible preparation process, the size of the novel quartz crucible of preparation is 24 inches, and it comprises the steps:

[0047] (1) Raw material preparation: Weigh 37.5kg of quartz sand that has passed the quality inspection and meets the production requirements, the total impurity content of natural quartz sand is ≤20ppm, and the proportion of quartz sand with a particle size of ≤150μm per unit weight is 15%;

[0048] (2) Debugging before prefabrication: (1) After the preparation of raw materials is completed, install the crucible mold and its jacket on the rotating shaft, tilt the crucible mold to the position where the angle between its axis and the horizontal plane is 84°, and then start the rotation Shaft, so that the rotating speed of the crucible mold is 76r / min;

[0049] (3) Prefabrication: (2) After the prefabrication debugging is completed, place the quartz sand in the crucible mold, and use a forming rod that meets ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com