Multi-roller cotton blending machine

A blending machine and roller technology, which is applied in the direction of fiber mixing, textile/flexible product manufacturing, climate sustainability, etc. It can solve the constraints of carding and processing in the subsequent process, many flying flowers on the shaft head, and easy discoloration and peeling of rubber curtains and other problems, to achieve the effect of continuous and efficient work efficiency, avoiding the number of cleaning shutdowns, and reasonable and beautiful machine design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

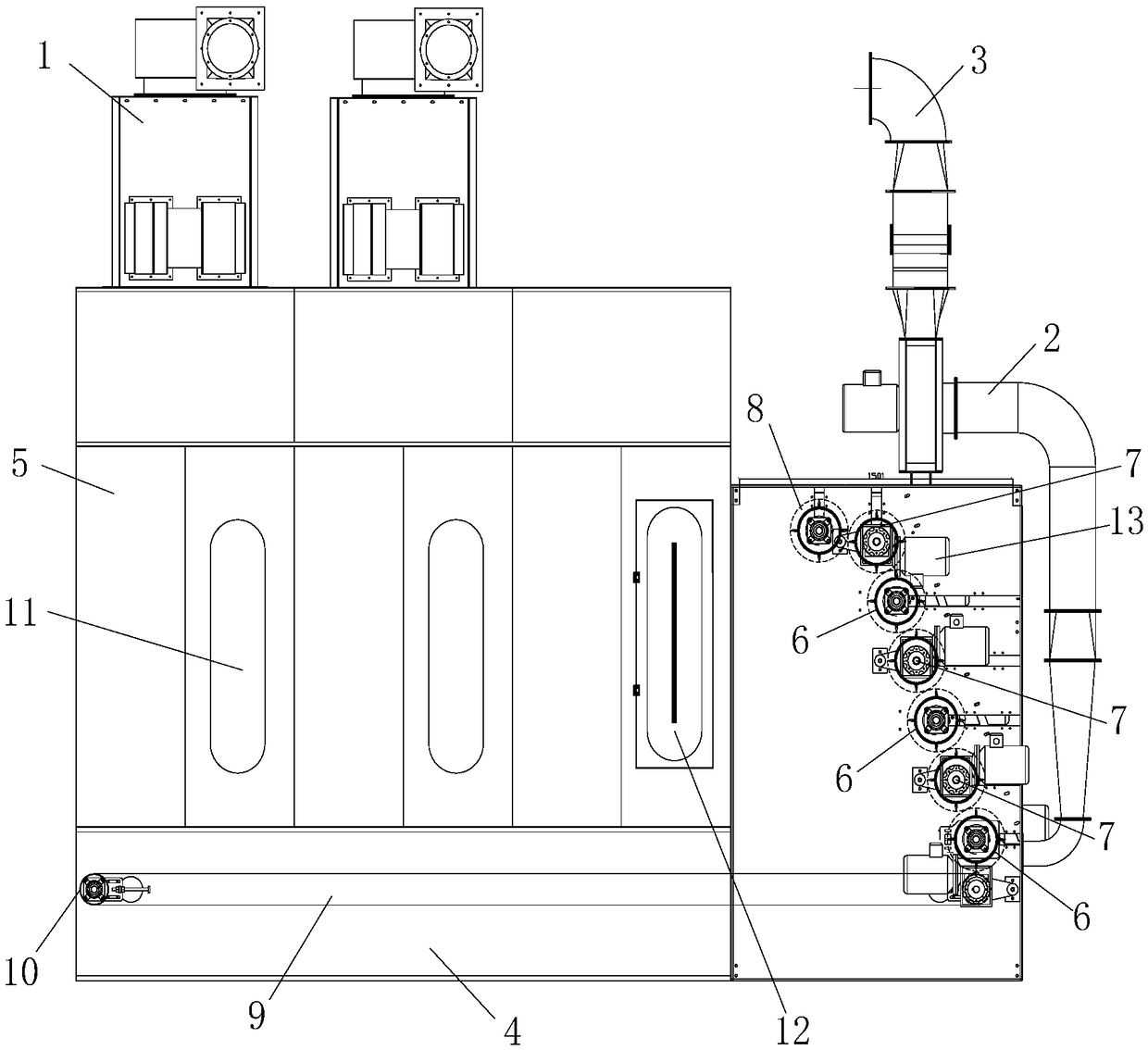

[0023] See figure 1 with figure 2 , the present invention includes one or more groups in series; the unit has a cotton condenser 1, an automatic cotton feeding mechanism, a multi-roller cotton layer conveying channel, an output pipeline 2, a cotton conveying fan system 3 and an electrical automation control system; the cotton condenser 1 is placed on the top of the cotton bin 5 installed on the wall panel frame 4; the automatic cotton feeding mechanism is set at the bottom of the cotton bin 5 and the multi-roller cotton layer conveying channel; the power of the cotton conveying fan system 3 is 5.5KW-2B, model Y-132S1-2, the cotton conveying fan system 3 is installed on the top of the wall panel frame 4, and the input port is connected to the output end of the multi-layer transmission transmission mechanism through the output pipe 2; the electrical automation control system is installed in the electrical control cabinet and placed side by side On any side of the wall panel fr...

Embodiment 2

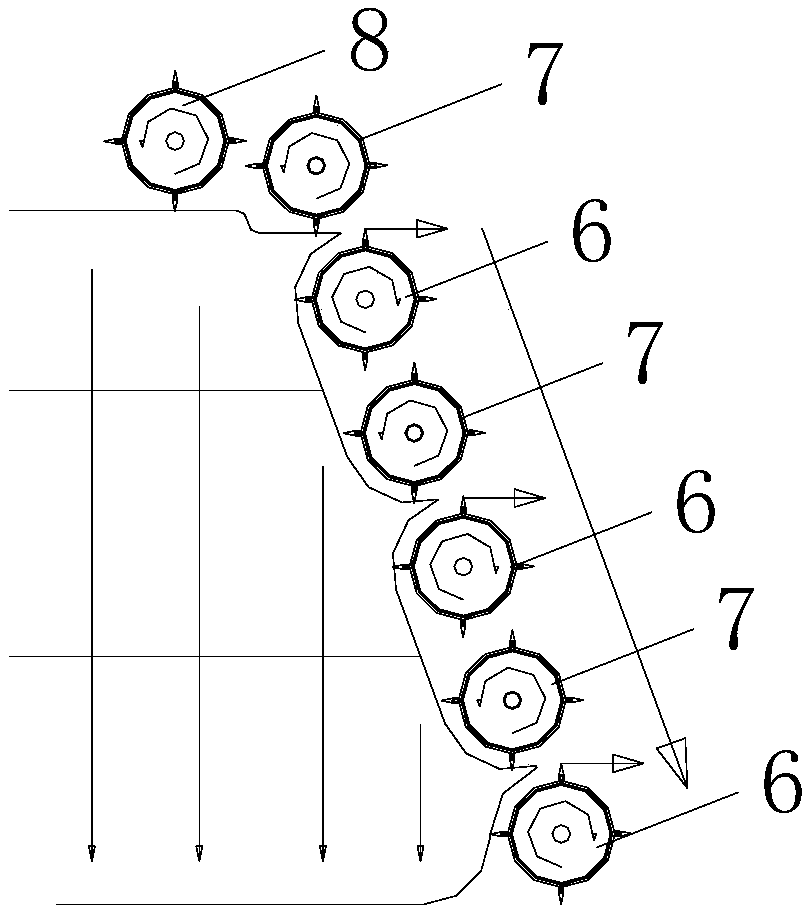

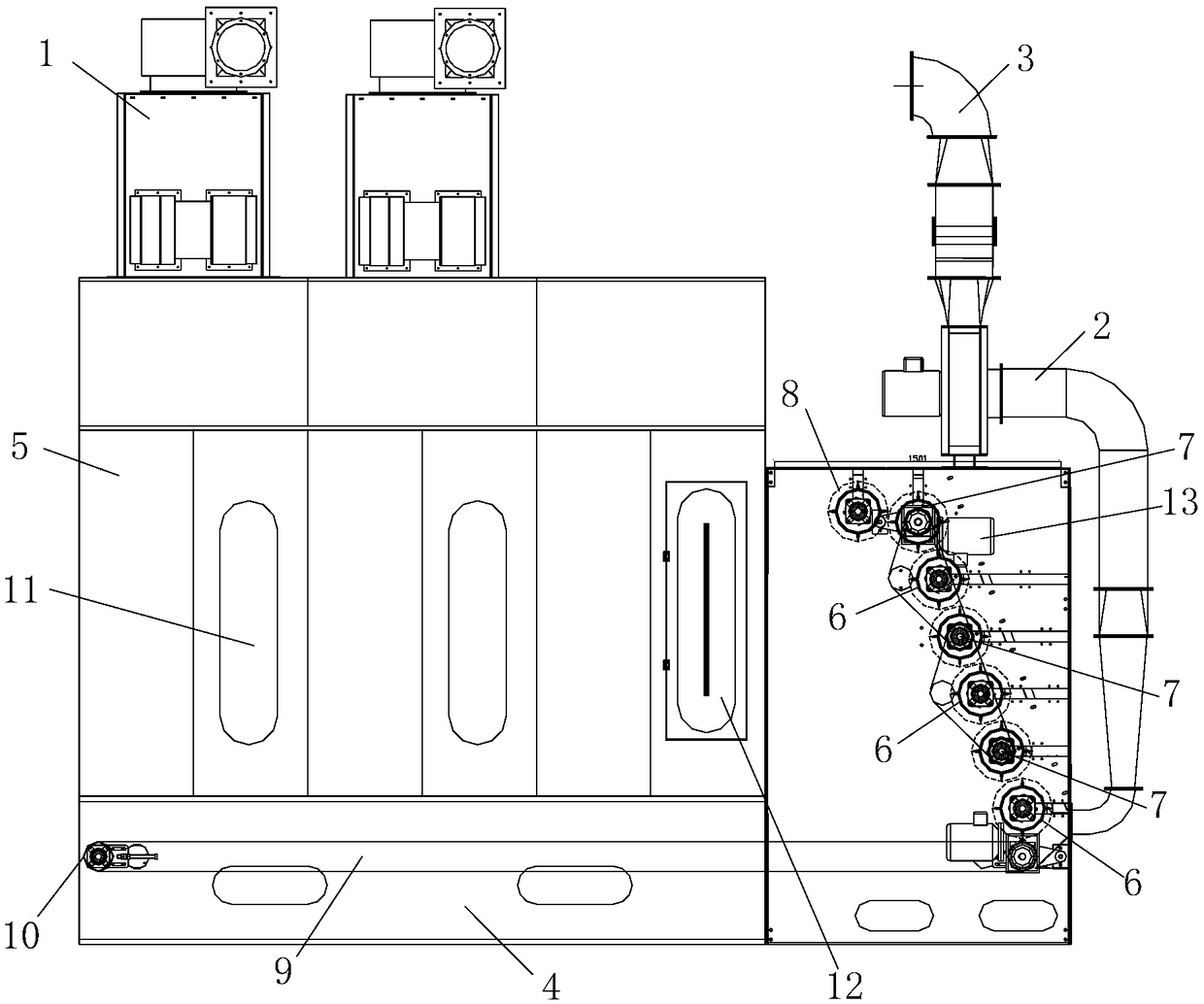

[0030] See Figure 3 to Figure 5, the present invention includes one or more groups in series; the unit has a cotton condenser 1, an automatic cotton feeding mechanism, a multi-roller cotton layer conveying channel, an output pipeline 2, a cotton conveying fan system 3 and an electrical automation control system; the cotton condenser 1 is placed on the top of the cotton bin 5 installed on the wall panel frame 4; the automatic cotton feeding mechanism is set at the bottom of the cotton bin 5 and the multi-roller cotton layer conveying channel; the cotton conveying fan system 3 is installed on the top of the wall panel frame 4 , and the input port is connected to the output end of the multi-layer conveying transmission mechanism through the output pipeline 2; the electric automation control system is installed in the electric control cabinet and placed on any side of the wall panel frame 4; the multi-roller cotton layer conveying channel is controlled by frequency conversion Dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com