Preparation method of high-sensitivity flexible strain sensor

A strain sensor and high-sensitivity technology, applied in the field of flexible sensors, can solve the problems of difficult combination of high sensitivity and high strain, limit the development and application of flexible sensors, and small strain range of flexible sensors, and achieve wide selectivity and good quality stability , the effect of good elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Step a: get 50 milligrams of water-based graphene and 50 milliliters of ethanol with a volume concentration of 98% and mix it with ultrasonic treatment for 10 minutes, then centrifuge it at 5000 rpm for 15 minutes, take the supernatant, and obtain the graphene Spreading fluid is ready for use.

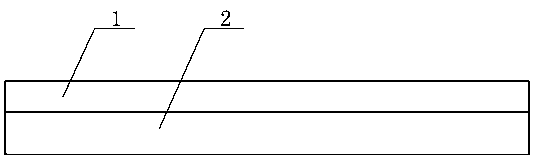

[0024] Step b: cleaning and hydrophilizing the PDMS substrate 2 with a plasma cleaner.

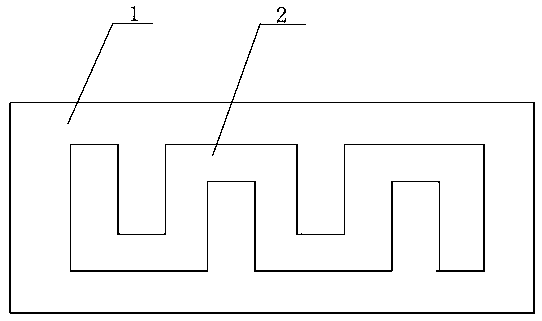

[0025] Step c: see attached figure 2 , using a laser etching machine to etch the desired shape of the graphene strained layer 3 on the PI tape 1 .

[0026] See attached image 3 , stick the patterned PI tape 1 on the PDMS substrate 2 .

[0027] Step d: Pour deionized water into the water tank of the "Langmuir" membrane analyzer as a subphase, and spread the graphene spreading solution prepared above drop by drop on the liquid surface of deionized water with a syringe, and let it stand for 40 minutes. After the ethanol is completely volatilized, a graphene layer is formed on the surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com