Reciprocating type grubbing principle based woodland weeding equipment for oil tea planting

A kind of weeding equipment, reciprocating technology, applied in the direction of applications, cutters, agricultural machinery and implements, etc., can solve the problems of increased weeding workload, inability to cut weed roots, waste, etc., achieve thorough weeding effect, improve the cutting range and effect, fully utilized effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

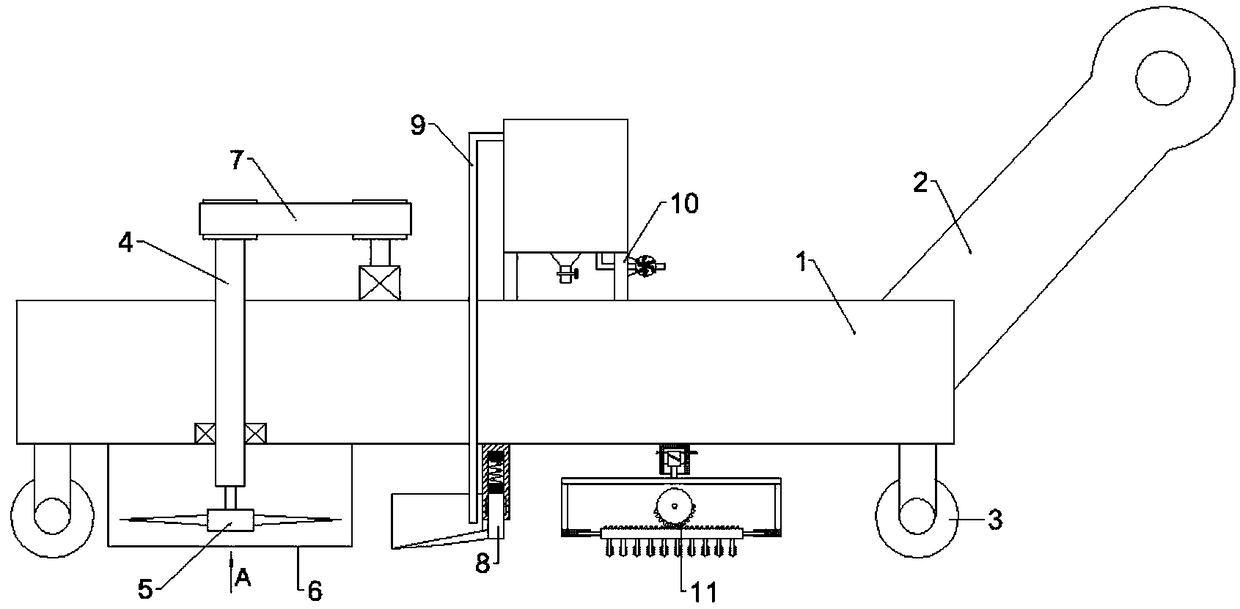

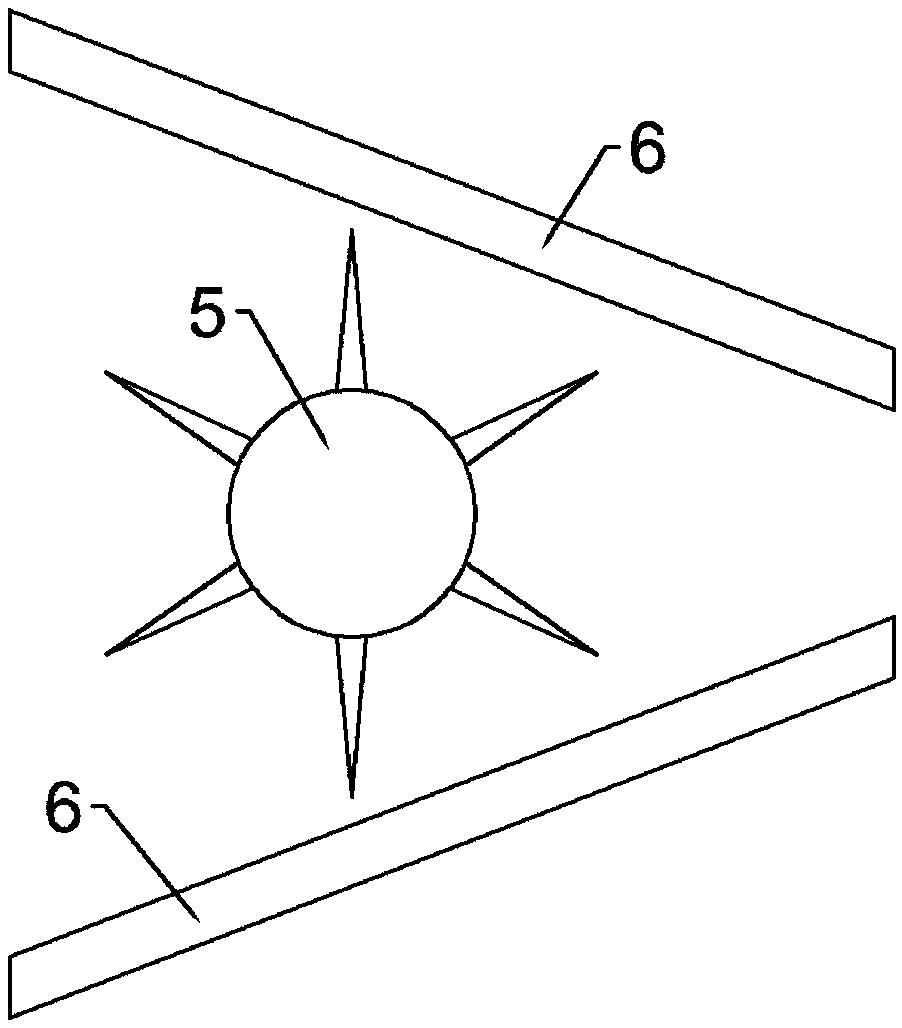

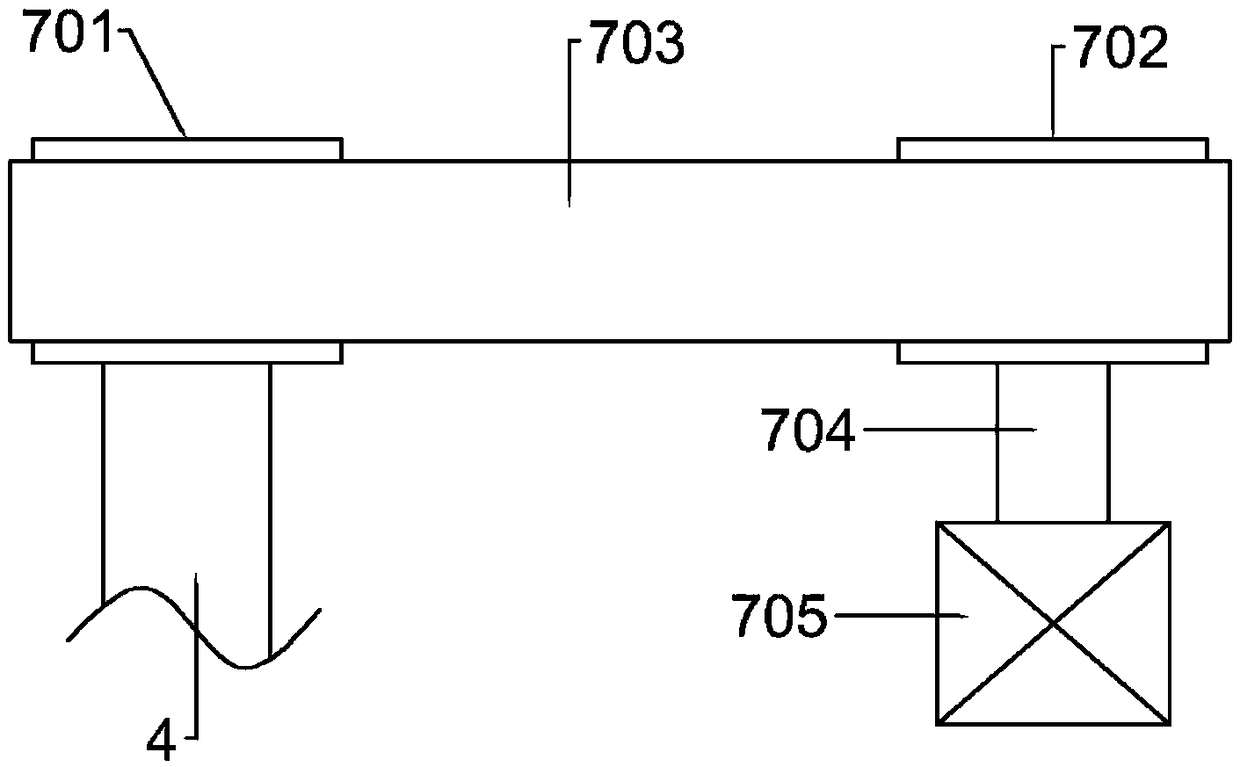

[0050] see figure 1 and figure 2 , in this embodiment, a kind of weeding equipment for camellia oleifera planting forestland based on the principle of reciprocating root removal, including a frame 1, a handle 2 is provided on the frame 1, and the four corners of the lower side of the frame 1 are connected with rollers 3, A drive shaft 4 passes through the frame 1, the drive shaft 4 is rotatably connected with the frame 1, the bottom end of the drive shaft 4 is fixedly connected with a cutter head 5, and a weed gathering device is arranged on the outer side of the cutter head 5. The weed gathering device includes two gathering plates 6, the upper ends of the two gathering plates 6 are fixedly connected with the lower side of the frame 1, and the two gathering plates 6 form a figure-eight shape, the driving device 7 drives the drive shaft 4 to rotate, and the drive shaft 4 drives the The cutter head 5 rotates, and the cutter head 5 cuts the weeds; in order to increase the cutt...

Embodiment 2

[0053] see figure 1 , Figure 4 and Figure 5 , the lower side of the frame 1 on the right side of the cutter head 5 is also provided with a weed collecting device 8, the weed collecting device 8 includes an inclined plate 801, and a first vertical column 803 is arranged on the right side of the inclined plate 801. The top of a vertical column 803 is fixedly connected to the lower side of the frame 1. The first vertical column 803 is provided with a first groove 804 with an opening facing downward, and a first magnetic pole 805 is fixedly connected to the top of the first groove 804. A second magnetic pole 807 is fixedly connected to the lower side of the first magnetic pole 805 through a first spring 806. The polarity of the first magnetic pole 805 is the same as that of the second magnetic pole 807. The bottom end of the column 808 is fixedly connected with the inclined plate 801. After the weeds are cut off, in order to collect them conveniently, a collecting device 8 is ...

Embodiment 3

[0055] see figure 1 and Image 6 , the inclined plate 801 is provided with a collection pipe 9, and the collection pipe 9 communicates with the storage device 10 located on the upper side of the rack 1. The storage device 10 includes four support frames 101, and the top of the support frames 101 is fixedly connected with a storage device 10. box 102, the collection pipe 9 communicates with the top of the storage box 102; and the bottom of the storage box 102 is provided with an exhaust pipe 103, and the exhaust pipe 103 is provided with a negative pressure fan 104, after the weeds are collected on the inclined plate 801, The negative pressure fan 104 is started, and the negative pressure fan 104 draws out the air in the storage box 102 through the exhaust pipe 103, so the storage box 103 is in a negative pressure state, and weeds can enter the storage box 103 through the collection pipe 9 under the action of air pressure The collected weeds can be used for animal husbandry, r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com