Small orchid tea processing method

A processing method and technology for orchid tea, which are applied in pre-extraction tea treatment, food science and other directions, can solve the problems of insufficient aroma and weak taste of small orchid tea, increase the generation of soluble sugar and aromatic substances, and make the tea soup taste fresh and pure. , strong aroma effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

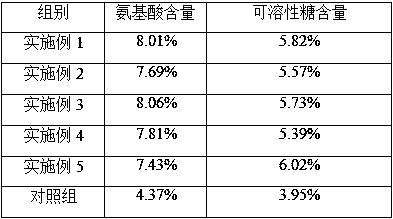

Examples

Embodiment 1

[0025] In an embodiment of the present invention, a processing method of small orchid tea comprises the following steps: spreading fresh leaves, killing greens, rolling, initial drying and foot drying, and aroma enhancing steps.

[0026] The processing method of the small orchid tea, the fresh leaves spread includes the steps of freezing, blowing and heating, soaking the picked fresh leaves in the ice-water mixture for 10 minutes, taking them out and draining them, wrapping them in cotton cloth and blowing hot air with a fan until the fresh leaves lose water and wither.

[0027] The processing method of small orchid tea, before blowing and heating step, mix edible baking soda, yeast powder, and small orchid tea according to the ratio of parts by weight of 3:1:15, and wash it with pure water after standing in a closed environment for 30 minutes.

[0028] The processing method of small orchid tea, the thickness of spreading is 6cm, and the time of blowing hot air is 3 hours.

[...

Embodiment 2

[0036] In an embodiment of the present invention, a processing method of small orchid tea comprises the following steps: spreading fresh leaves, killing greens, rolling, initial drying and foot drying, and aroma enhancing steps.

[0037] The processing method of the small orchid tea, the fresh leaves spread includes the steps of freezing, blowing and heating, soaking the picked fresh leaves in the ice-water mixture for 10 minutes, taking them out and draining them, wrapping them in cotton cloth and blowing hot air with a fan until the fresh leaves lose water and wither.

[0038] The processing method of small orchid tea, before blowing and heating step, mix edible baking soda, yeast powder, and small orchid tea according to the ratio of parts by weight of 3:1:15, and wash it with pure water after standing in a closed environment for 20 minutes.

[0039] The processing method of small orchid tea, the thickness of spreading is 5cm, and the time of blowing hot air is 2 hours.

[...

Embodiment 3

[0047] In an embodiment of the present invention, a processing method of small orchid tea comprises the following steps: spreading fresh leaves, killing greens, rolling, initial drying and foot drying, and aroma enhancing steps.

[0048]The processing method of the small orchid tea, the fresh leaves spread includes the steps of freezing, blowing and heating, soaking the picked fresh leaves in the ice-water mixture for 5 minutes, taking them out and draining them, wrapping them in cotton cloth and blowing hot air with a fan until the fresh leaves lose water and wither.

[0049] The processing method of small orchid tea, before blowing and heating step, mix edible baking soda, yeast powder, and small orchid tea according to the ratio of parts by weight of 3:1:15, and wash it with pure water after standing in a closed environment for 20 minutes.

[0050] The processing method of small orchid tea, the thickness of spreading is 8cm, and the time of blowing hot air is 2 hours.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com