Extraction method of sea cucumber collagen fiber

A collagen fiber and extraction method technology, applied in the field of sea cucumber collagen fiber extraction, can solve the problems of containing other impurities, incomplete collagen fiber structure, difficult extraction, etc., and achieve the effects of avoiding degradation and damage, uniform diameter, and simple operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

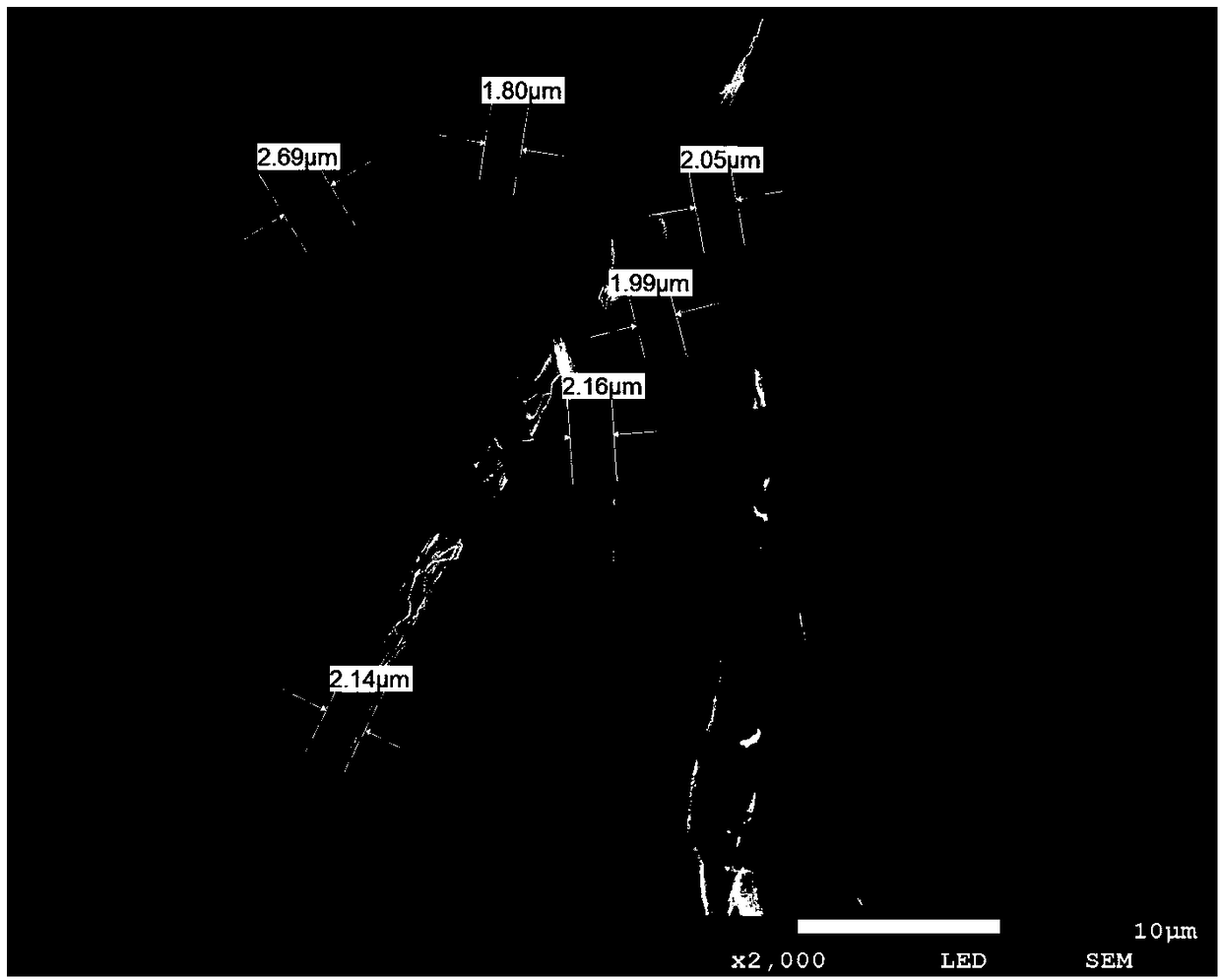

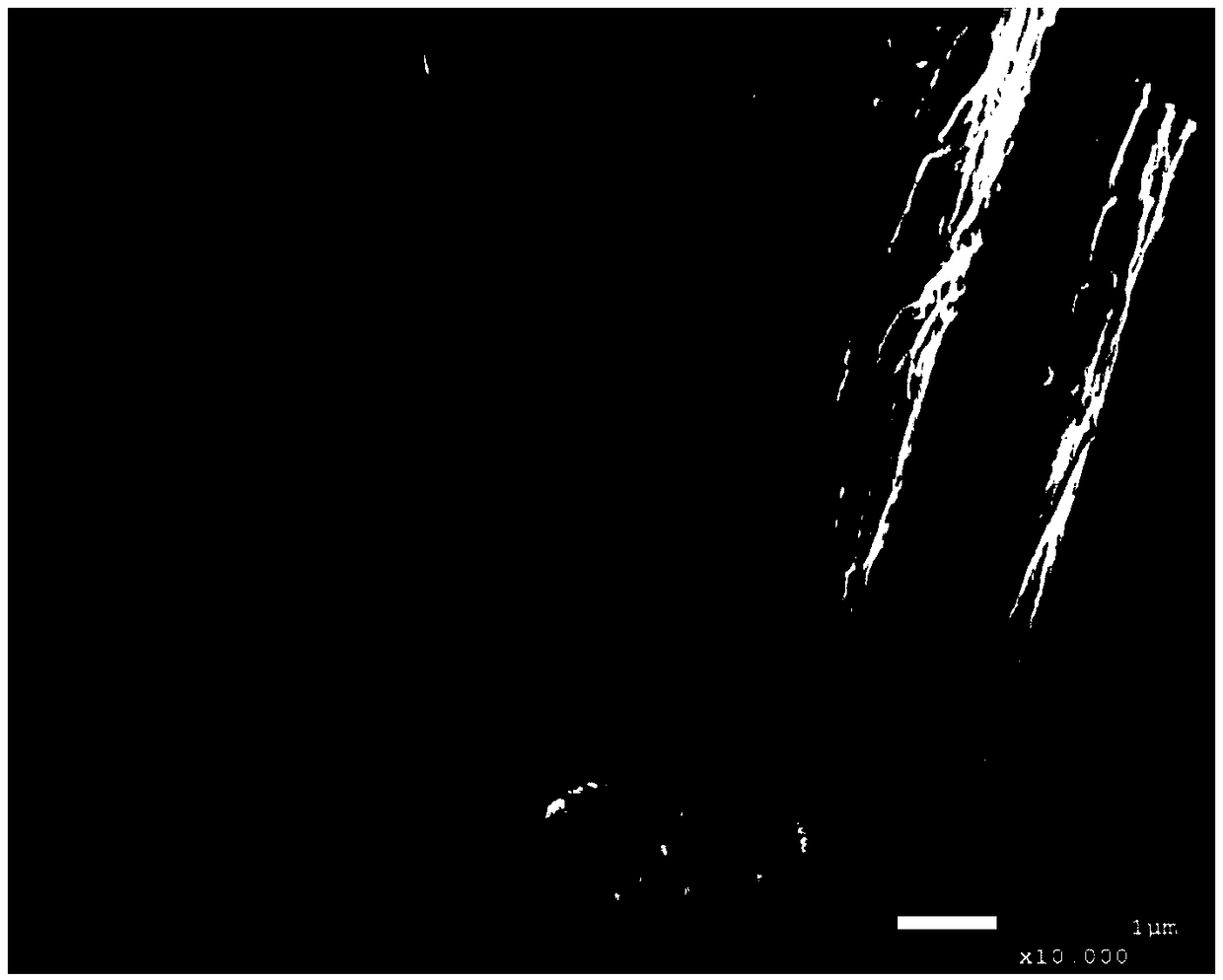

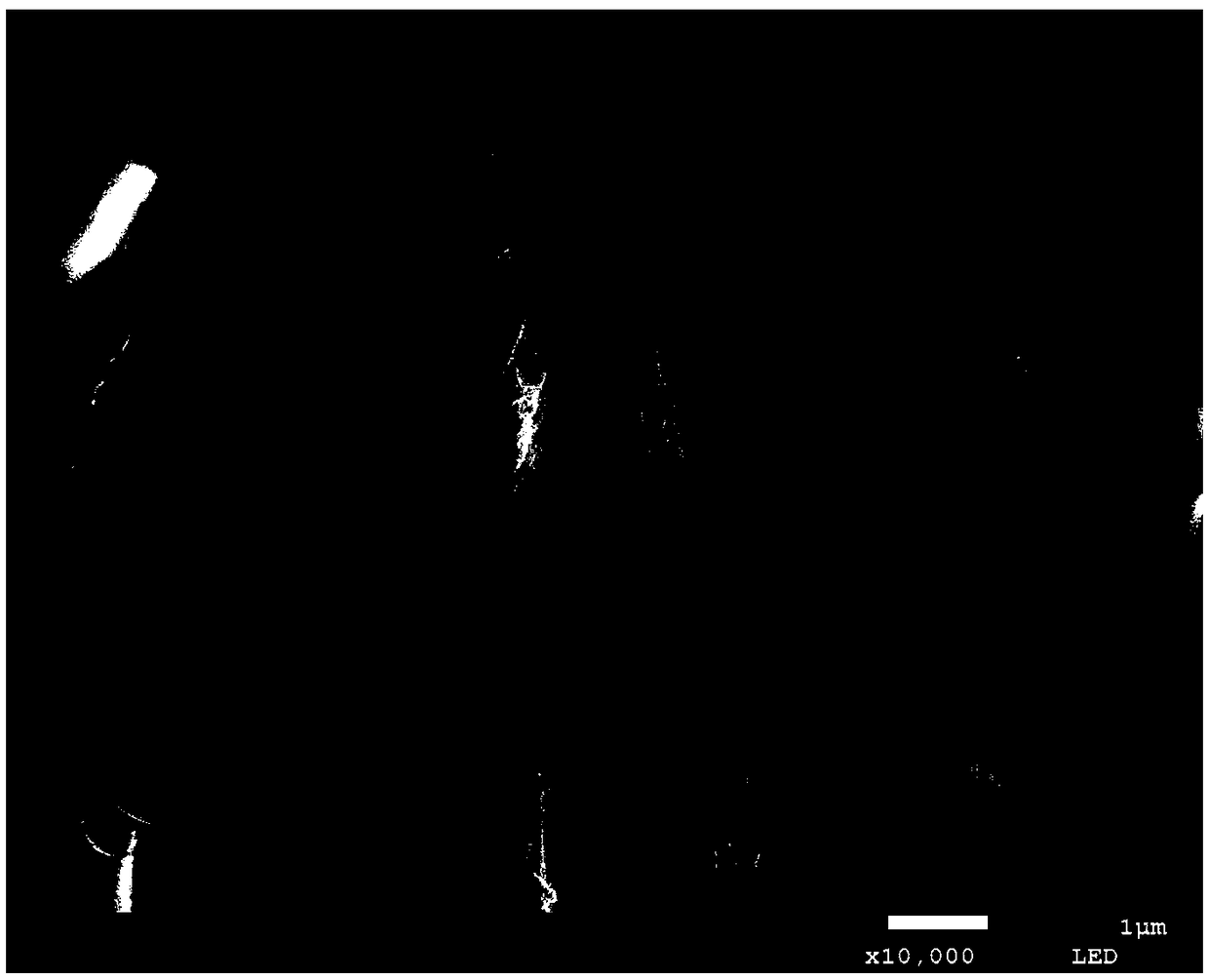

Image

Examples

Embodiment 1

[0041] S1. Fresh sea cucumber pretreatment: remove the anus, mouth, tentacles, viscera and contractile muscles of the fresh sea cucumber, clean them, and cut the resulting body wall into about 4cm 3 Small pieces, put at 0 ℃ for later use;

[0042] S2, one-time water washing: take the small pieces of sea cucumber body wall obtained in step S1, add 2 times the weight of water at 0°C, use a beater at 18,000 rpm, 4s / time×3 times, and prepare sea cucumber pulp at an interval of 30s each time; The sea cucumber slurry was stirred at 0°C for 1 hour, centrifuged at 10,000×g for 5 minutes, and the precipitate was collected;

[0043] S3. Secondary water washing: Add 2 times the weight of 0°C water to the precipitate obtained in step S2, stir at 0°C for 1 hour, centrifuge at 10,000×g for 5 minutes, and discard the precipitate; the purpose of the above two steps S2 and S3 is to initially remove Water-soluble impurities in sea cucumber body wall;

[0044] S4. Buffer washing: Add 2 times t...

Embodiment 2

[0051] S1. Fresh sea cucumber pretreatment: remove the anus, mouth, tentacles, viscera and contractile muscles of the fresh sea cucumber, clean them, and cut the body wall of the sea cucumber into about 9cm 3 Small pieces, put at 4°C for later use;

[0052] S2. One-time water washing: take the small pieces of sea cucumber body wall obtained in step S1, add 10 times the weight of water at 4°C, use a homogenizer at 23,000 rpm, 10 s / time x 3 times, and prepare sea cucumber slurry at an interval of 30 s each time; The obtained sea cucumber slurry was stirred at 4°C for 3 hours, centrifuged at 15,000×g for 20 minutes, and the supernatant was discarded to obtain a precipitate;

[0053] S3. Second washing: Add 10 times the weight of water at 4°C to the precipitate obtained in step S2, stir at 4°C for 3 hours, centrifuge at 15,000×g for 20 minutes, discard the supernatant, and collect the precipitate; the above two steps of S2 and S3 The purpose is to initially remove water-soluble i...

Embodiment 3

[0061] S1. Fresh sea cucumber pretreatment: remove the anus, mouth, tentacles, viscera and contractile muscles of fresh sea cucumbers, clean them, and cut them into about 6cm 3 Small pieces, set aside at 3°C;

[0062] S2. One-time water washing: take the small piece of sea cucumber body wall obtained in step S1, add 6 times the weight of water at 3°C, 20000 rpm, 8s / time×3 times, and prepare sea cucumber slurry at an interval of 30s each time; the obtained sea cucumber slurry is prepared in 3 Stir at ℃ for 2 hours, centrifuge at 12800×g for 12 minutes, discard the supernatant to obtain a precipitate;

[0063] S3, secondary water washing: add 6 times the weight of 3°C water to the precipitate obtained in step S2, stir at 3°C for 2 hours, centrifuge at 12800×g for 12 minutes, discard the supernatant, and collect the precipitate; the above two steps of S2 and S3 The purpose is to initially remove water-soluble impurities in the body wall of sea cucumbers;

[0064] S4. Buffer w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com