Vacuum pulse hydrogen peroxide sterilization device for medicinal aluminum tube sterilization

A hydrogen peroxide and vacuum pulsation technology, applied in water supply devices, sanitary equipment for toilets, chemistry, etc., can solve the problems of affecting the quality of aluminum pipes, inconvenient process control, and bacterial contamination of aluminum pipes, and shorten the sterilization cycle. , the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below, the applicant further describes the technical solution of the present invention in detail in conjunction with specific examples, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the scope of protection claimed by the present invention.

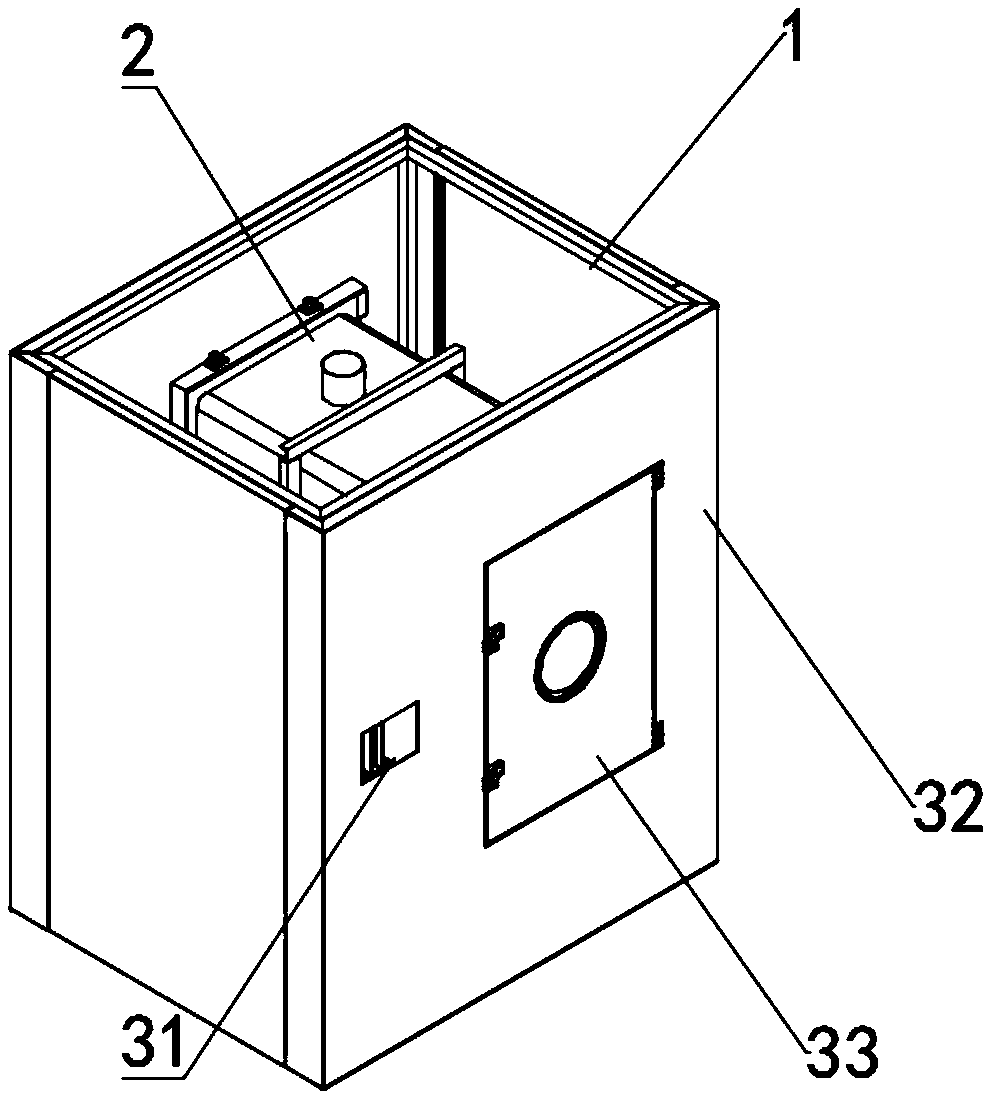

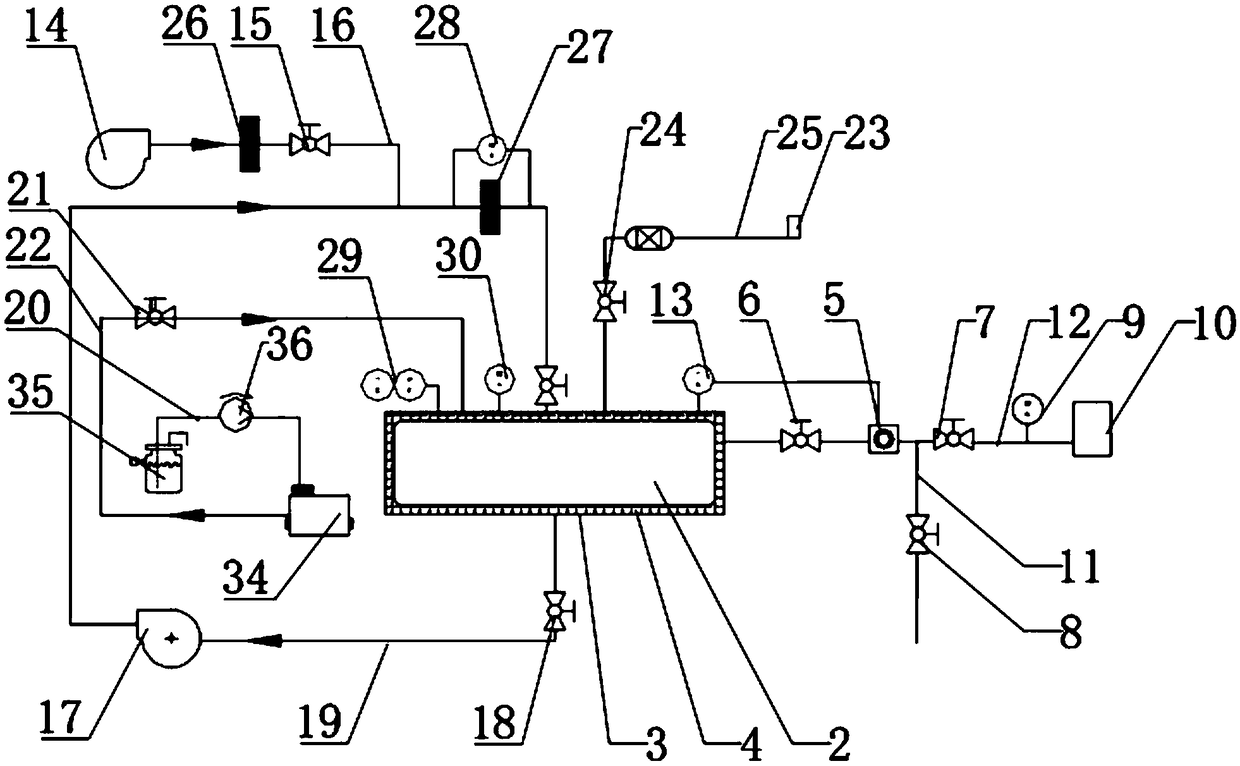

[0023] The invention provides a vacuum pulse hydrogen peroxide sterilizing device for sterilizing medicinal aluminum tubes, such as figure 1 As shown, it includes a cabinet body 1 and a cabinet door 32. The cabinet body 1 is provided with a sterilization chamber 2 for placing aluminum tubes to be sterilized, a computer control system for intelligently monitoring the sterilization state and controlling the sterilization process ( Not shown in the figure), control display interface 31, viewing mirror observation window 33; a heating jacket 3 is arranged outside the sterilization chamber 2, and an electric heating wire 4 is arranged inside ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com