Ferrous malate production method

A ferrous malate and production method technology, which is applied in chemical instruments and methods, carboxylate preparation, carboxylate preparation, etc., can solve the problems of low production efficiency and poor product quality, and achieve the improvement of production efficiency and product quality , Reliable product performance, easy to summarize and accumulate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

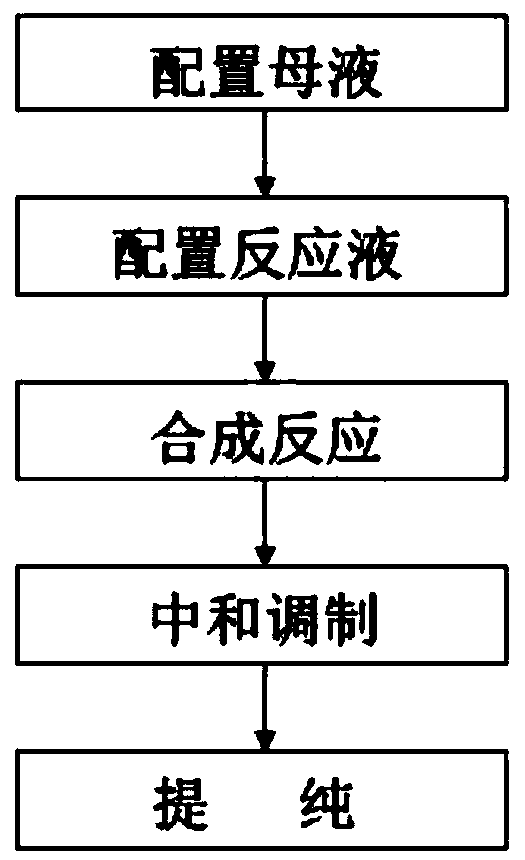

[0022] Such as figure 1 Shown a kind of production method of ferrous malate, comprises the steps:

[0023] (1) Prepare the mother liquor: first mix sodium carbonate and deionized water at a ratio of 1:4 in the main reactor to prepare a sodium carbonate aqueous solution, and then heat the sodium carbonate aqueous solution to 30°C at a uniform rate within 5 minutes by irradiating. Then add malic acid to the sodium carbonate aqueous solution until the pH value of the solution in the main reactor reaches 5.0, then let the solution in the reactor stand and naturally cool to normal temperature to obtain the finished mother liquor and set aside;

[0024] (2) To configure the reaction solution, first pass inert gas into the auxiliary reactor to keep the pressure in the reactor constant at 0.9 times the standard atmospheric pressure, and the oxygen content in the reactor is lower than 2%, then solid ferrous lactate and deionized Water was added to the auxiliary reactor at a ratio of 1...

Embodiment 2

[0034] Such as figure 1 Shown a kind of production method of ferrous malate, comprises the steps:

[0035] (1) Prepare the mother liquor: first mix sodium carbonate and deionized water at a ratio of 1:8 in the main reactor to prepare a sodium carbonate aqueous solution, and then heat the sodium carbonate aqueous solution to 45°C at a uniform rate within 10 minutes by irradiating it. Then add malic acid to the sodium carbonate aqueous solution until the pH value of the solution in the main reactor reaches 6.5, then let the solution in the reactor stand and naturally cool to normal temperature to obtain the finished mother liquor and set aside;

[0036] (2) To configure the reaction solution, first pass inert gas into the auxiliary reactor to keep the pressure in the reactor constant at 1.3 times the standard atmospheric pressure, and the oxygen content in the reactor is lower than 2%, then solid ferrous lactate and deionized Water was added to the auxiliary reactor at a ratio ...

Embodiment 3

[0046] Such as figure 1 Shown, a kind of production method of ferrous malate comprises the steps:

[0047] (1) Prepare the mother liquor: first mix sodium carbonate and deionized water at a ratio of 1:6.5 in the main reactor to prepare a sodium carbonate aqueous solution, and then heat the sodium carbonate aqueous solution to 35°C at a uniform rate within 6.5 minutes by irradiating. Then add malic acid to the sodium carbonate aqueous solution until the pH value of the solution in the main reactor reaches 6, then let the solution in the reactor stand and naturally cool to normal temperature to obtain the finished mother liquor and set aside;

[0048] (2) To configure the reaction solution, first pass inert gas into the auxiliary reactor to keep the pressure in the reactor constant at 1 times the standard atmospheric pressure, and the oxygen content in the reactor is lower than 2%, and then the solid ferrous lactate and deionized Water was added to the auxiliary reactor at a ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com