Low-odor low-toxicity plastic floor elastic layer and production process thereof

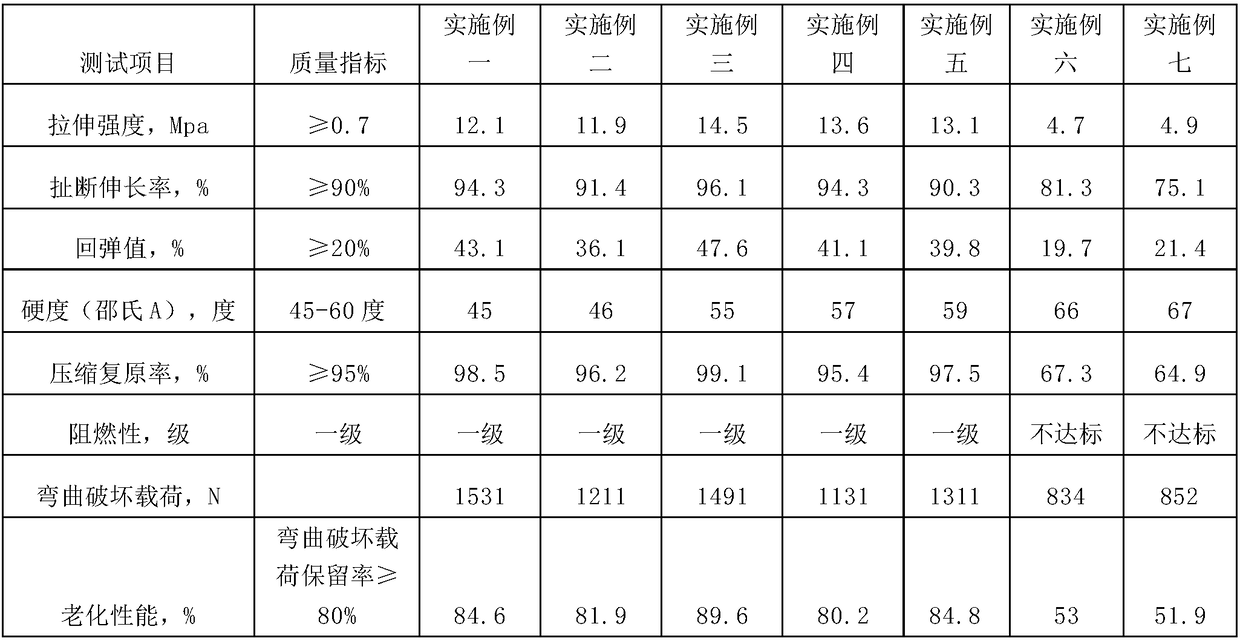

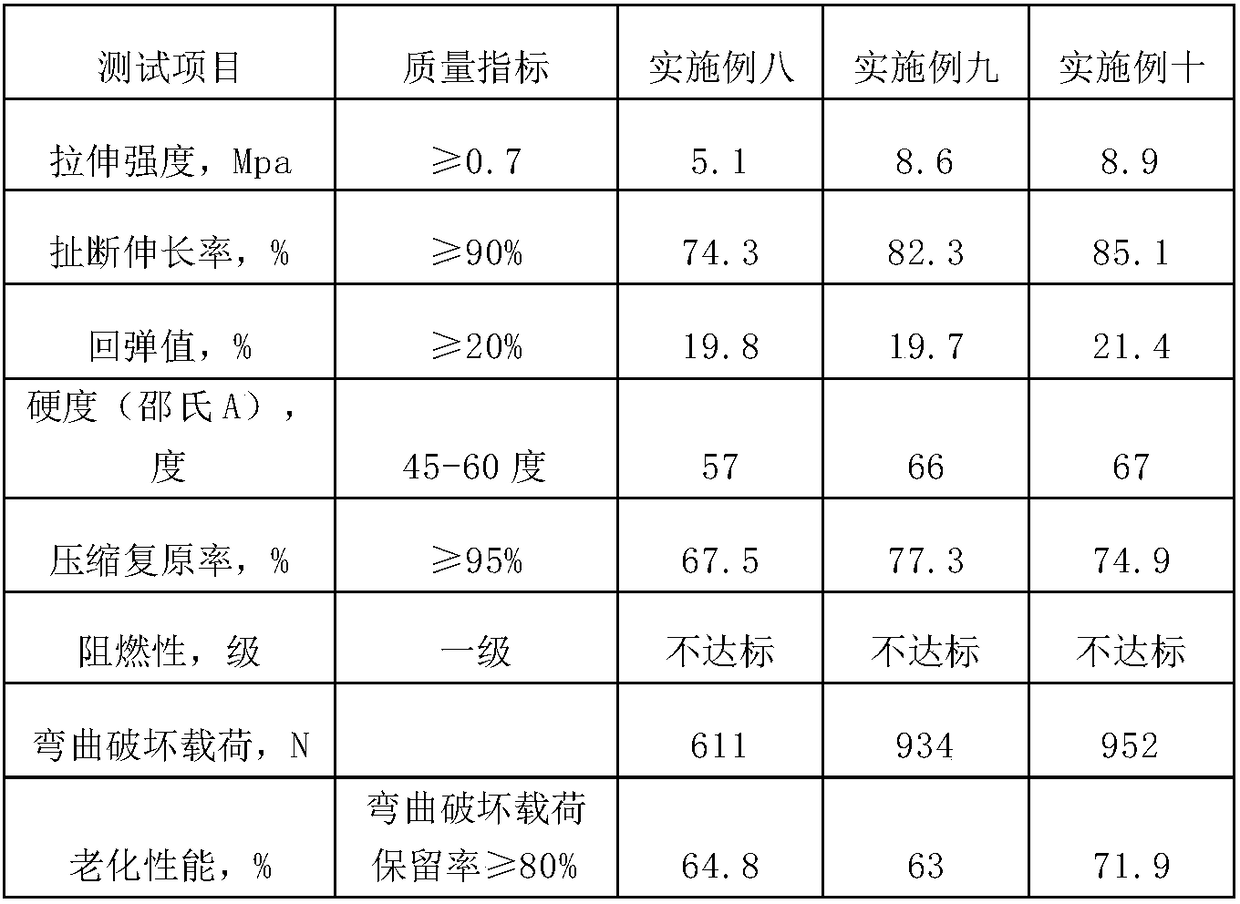

A technology of plastic floor and elastic layer, applied in the field of floor production, can solve the problems of tensile strength, elongation at break, rebound value, compression recovery rate, unreachable flame retardancy, and aging performance below 53%, etc. Achieve good aging resistance, reduce slip and fall injuries, and light weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A low-odor and low-toxic plastic floor elastic layer is prepared from the following raw materials:

[0042] The first component raw material kg: polyether polyol 330: 1050; talcum powder: 300; color paste: 14; toluene: 220;

[0043] Second component raw material kg: diphenyldichlorosilane: 0.484; MDI: 100; dibutyltin dilaurate: 0.717; white carbon black: 22.

[0044] The processing steps of the elastic layer are as follows: put the first component raw materials into the reaction tank and stir, heat up to 200°C for dehydration; keep warm for 1 hour; add diphenyldichlorosilane first at 93°C, then add MDI at 90°C, Add dibutyltin dilaurate between 85-90°C, keep warm at 85-90°C for 3.5 hours, cool down to 50°C and discharge to obtain elastic layer coating.

Embodiment 2

[0046] A low-odor and low-toxic plastic floor elastic layer is prepared from the following raw materials:

[0047] The first component raw material kg: polyether polyol 330: 1150; talcum powder: 310; color paste: 15; toluene: 230;

[0048] Second component raw material kg: diphenyldichlorosilane: 0.484; MDI: 105; dibutyltin dilaurate: 0.717; white carbon black: 22.

[0049] The processing steps of the elastic layer are as follows: put the first component raw materials into the reaction tank and stir, heat up to 200°C for dehydration; keep warm for 1 hour; add diphenyldichlorosilane first at 93°C, then add MDI at 90°C, Add dibutyltin dilaurate between 85-90°C, keep warm at 85-90°C for 3.5 hours, cool down to 50°C and discharge to obtain elastic layer coating.

Embodiment 3

[0051] A low-odor and low-toxic plastic floor elastic layer is prepared from the following raw materials:

[0052] The first component raw material kg: polyether polyol 330: 1200; talcum powder: 350; color paste: 16; toluene: 235;

[0053] Second component raw material kg: diphenyldichlorosilane: 0.484; MDI: 106; dibutyltin dilaurate: 0.717; white carbon black: 22.

[0054] The processing steps of the elastic layer are as follows: put the first component raw materials into the reaction tank and stir, heat up to 200°C for dehydration; keep warm for 1 hour; add diphenyldichlorosilane first at 93°C, then add MDI at 90°C, Add dibutyltin dilaurate between 85-90°C, keep warm at 85-90°C for 3.5 hours, cool down to 50°C and discharge to obtain elastic layer coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com