PE-PMMA (polyethylene-polymethyl methacrylate) ester-plastic material and preparation method thereof

A technology of modified materials and dyes, which is applied in the field of PE-PMMA plastic materials and their preparation, can solve the problems of increased mechanical properties, easy cracking and crushing, and excessive rigidity, so as to increase the bending failure load and the impact of falling balls Strength, the effect of improving mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

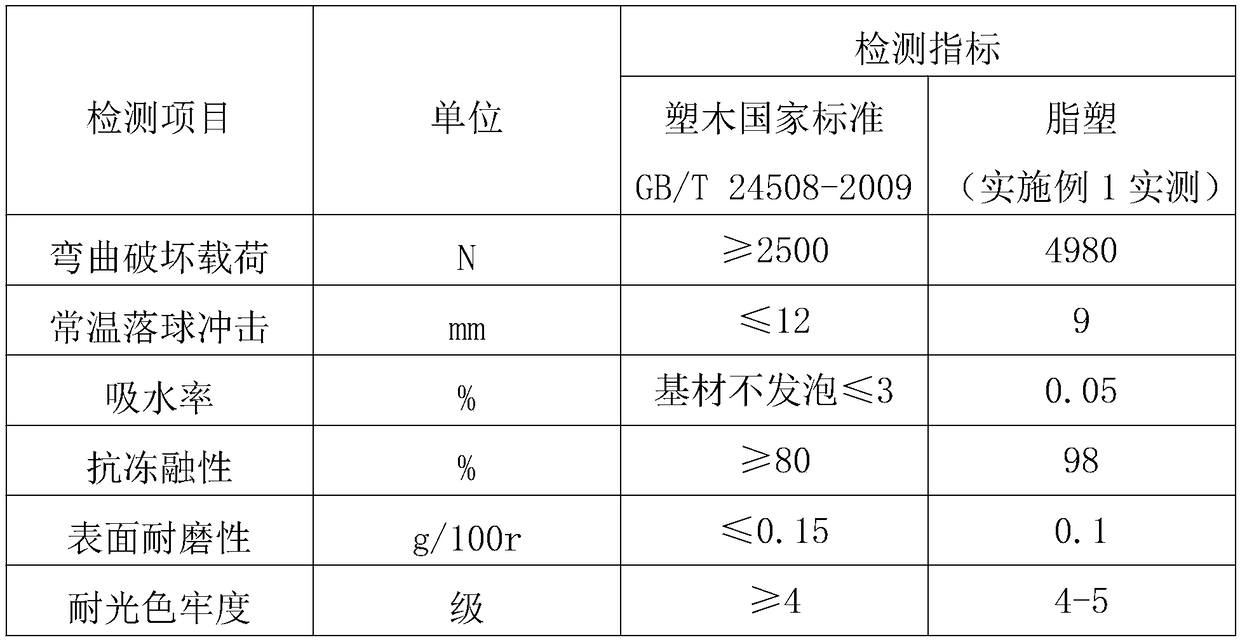

Examples

Embodiment 1

[0031] Put 26 parts of wood powder particles into a drying machine with a drying temperature of 80° C. to obtain dried wood powder particles;

[0032] Add 18 parts of polymethacrylate recycled materials, 5 parts of polystyrene-butadiene copolymer recycled materials, and 24 parts of epoxy resin powder into a high-speed mixer and mix evenly. The temperature of the high-speed mixer is 90 ° C;

[0033] The wood powder particles, 20 parts of polyethylene, 1 part of EBS lubricant, 0.4 part of antioxidant 1010, 1.5 parts of maleic anhydride grafted polyethylene, 0.4 part of ACR impact modifier, 1 part of iron oxide The red dye is added to the ingredients in the high-speed mixer together to obtain uniformly mixed ingredients. The temperature of the high-speed mixer is 90°C;

[0034] Pass the uniformly mixed ingredients into a granulator for kneading and granulation to obtain resin plastic particles. During the granulation process, the parameters of the twin-screw extruder are 165°C in...

Embodiment 2

[0037] A method for preparing PE-PMMA resin plastic material, comprises the following steps:

[0038] Step 1: Put 25 parts of wood powder particles into a drying machine with a drying temperature of 70° C. to obtain dried wood powder particles;

[0039] Step 2: Add 17 parts of polymethacrylate recycled materials, 4 parts of polystyrene-butadiene copolymer recycled materials, and 24 parts of epoxy resin powder into the high-speed mixer and mix evenly. The temperature of the high-speed mixer is 90°C;

[0040] Step 3: The wood powder particles dried in step 1, and 18 parts of polyethylene, 1 part of EBS lubricant, 0.2 part of 1010 antioxidant, 1 part of maleic anhydride grafted polyethylene, 0.3 part of ACR impact-resistant processing modification Add the agent and 1 part of the dye to the ingredients in the high-speed mixer to obtain uniformly mixed ingredients. The temperature of the high-speed mixer is 90°C;

[0041] Step 4: Pass the uniformly mixed ingredients into a granul...

Embodiment 3

[0044] A method for preparing PE-PMMA resin plastic material, comprises the following steps:

[0045]Step 1: put 27 parts of wood powder particles into a dryer with a drying temperature of 80° C. to obtain dried wood powder particles;

[0046] Step 2: Add 19 parts of polymethacrylate recycled materials, 5 parts of polystyrene-butadiene copolymer recycled materials, and 26 parts of epoxy resin powder into a high-speed mixer for uniform mixing. The temperature of the high-speed mixer is 90°C;

[0047] Step 3: The wood powder particles dried in step 1, and 21 parts of polyethylene, 2 parts of EBS lubricant, 0.5 part of 1010 antioxidant, 2 parts of maleic anhydride grafted polyethylene, 0.5 part of ACR impact-resistant processing modification The agent and 2 parts of dyes are added to the ingredients in the high-speed mixer to obtain uniformly mixed ingredients. The temperature of the high-speed mixer is 90°C;

[0048] Step 4: Pass the uniformly mixed ingredients into a granulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com