Method for preparing lipid-plastic composite material by adopting surface-activated epoxy resin powder

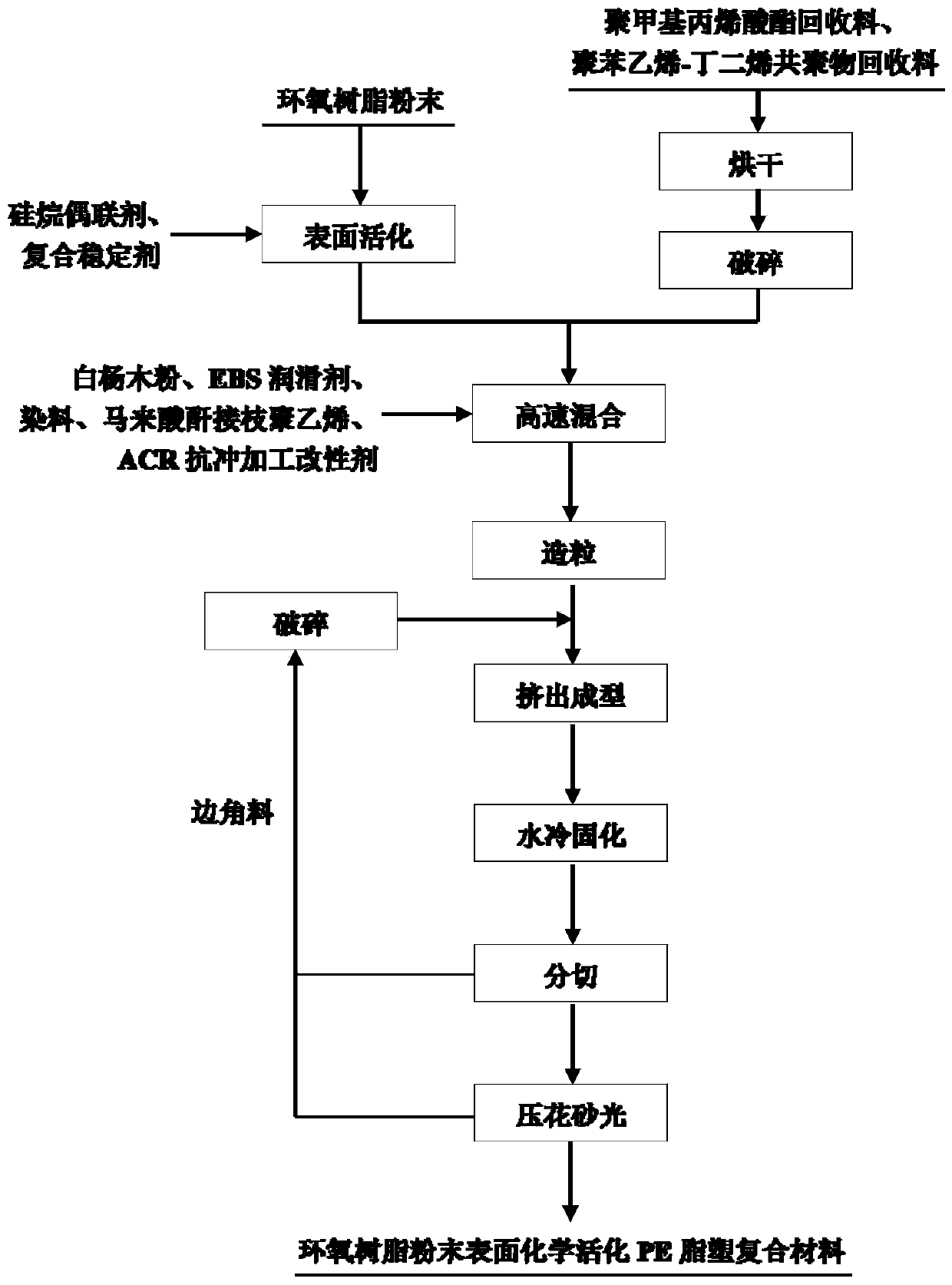

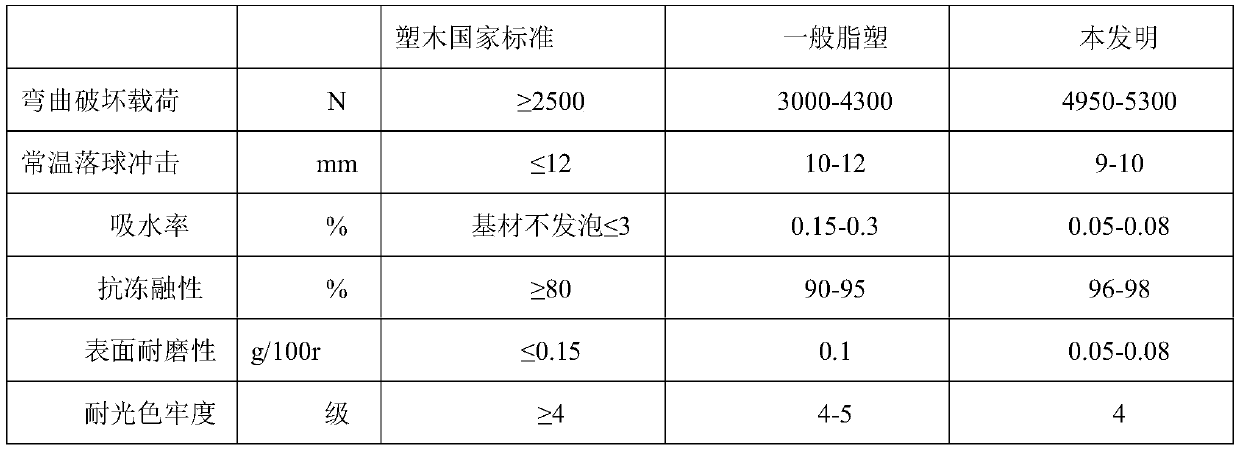

A technology of epoxy resin powder and surface activation, which is applied in the field of preparing PE resin-plastic composite materials by using surface chemically activated epoxy resin powder, can solve the problems of poor compatibility, low efficiency of selective cross-linking coupling reaction, etc., so as to improve the strength of materials , Improve the interfacial compatibility between epoxy resin powder/PE and the number of cross-linking chemical bonds, and improve the effect of bending failure load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0031] Add 25 parts of epoxy resin powder, 1 part of silane coupling agent KH-550, and 1 part of Ca-Zn composite stabilizer into a high-speed mixer for heating and blending to activate the surface. The rotor speed of the high-speed mixer is 80rmp and the temperature is 85°C , the surface activation time is 25min to obtain raw material 1; add 20 parts of polymethacrylate recycled materials and 5 parts of polystyrene-butadiene copolymer recycled materials into the hollow paddle dryer, and dry until the moisture content is below 5% After that, put it into a crusher and crush it to 100 meshes to obtain raw material 2; raw material 1, raw material 2 and 23 parts of poplar wood powder, 21 parts of PE particles, 2 parts of EBS lubricant, 1.5 parts of maleic anhydride grafted polyethylene, Add 0.5 parts of ACR impact modifier and 2 parts of titanium dioxide into a high-speed mixer and mix evenly. The rotor speed of the high-speed mixer is 45rmp, and mix at a high speed for 15 minutes t...

example 2

[0033]Add 23 parts of epoxy resin powder, 0.5 parts of silane coupling agent KH-550, and 0.5 parts of Ca-Zn composite stabilizer into a high-speed mixer for heating and blending to activate the surface. The rotor speed of the high-speed mixer is 75rmp and the temperature is 75°C , the surface activation time is 30min to obtain raw material 1; add 25 parts of polymethacrylate recycled materials and 6 parts of polystyrene-butadiene copolymer recycled materials into the hollow paddle dryer, and dry until the moisture content is below 5% Finally, put it into a crusher and crush it to 100 mesh to obtain raw material 2; raw material 1, raw material 2 and 23 parts of bamboo powder, 20 parts of PE particles, 1.5 parts of EBS lubricant, 1.5 parts of maleic anhydride grafted polyethylene, 0.5 Add one part of ACR impact-resistant processing modifier and two parts of carbon black into a high-speed mixer and mix evenly. The rotor speed of the high-speed mixer is 40rmp, and the high-speed mi...

example 3

[0035] Add 24 parts of epoxy resin powder, 0.5 parts of silane coupling agent KH-550, and 0.5 parts of Ca-Zn composite stabilizer into a high-speed mixer for heating and blending to activate the surface. The rotor speed of the high-speed mixer is 75rmp and the temperature is 75°C , the surface activation time is 28min to obtain raw material 1; add 24 parts of polymethacrylate recycled materials and 5 parts of polystyrene-butadiene copolymer recycled materials into the hollow paddle dryer, and dry until the moisture content is below 5% Finally, put it into a crusher and crush it to 100 mesh to obtain raw material 2; raw material 1, raw material 2 and 24 parts of poplar wood powder, 22 parts of PE particles, 1.5 parts of EBS lubricant, 1.5 parts of maleic anhydride grafted polyethylene, Add 0.5 parts of ACR impact modifier and 2 parts of iron oxide yellow into a high-speed mixer and mix evenly. The rotor speed of the high-speed mixer is 40rmp, and mix at high speed for 18 minutes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com