Enhanced mineral cotton acoustic board and preparation method thereof

A mineral wool sound-absorbing panel, a new type of technology, applied in the field of building decoration materials and its preparation, can solve the problems of inapplicable purity and directional growth of whiskers, and achieve the effects of reducing production costs, realizing waste reuse, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

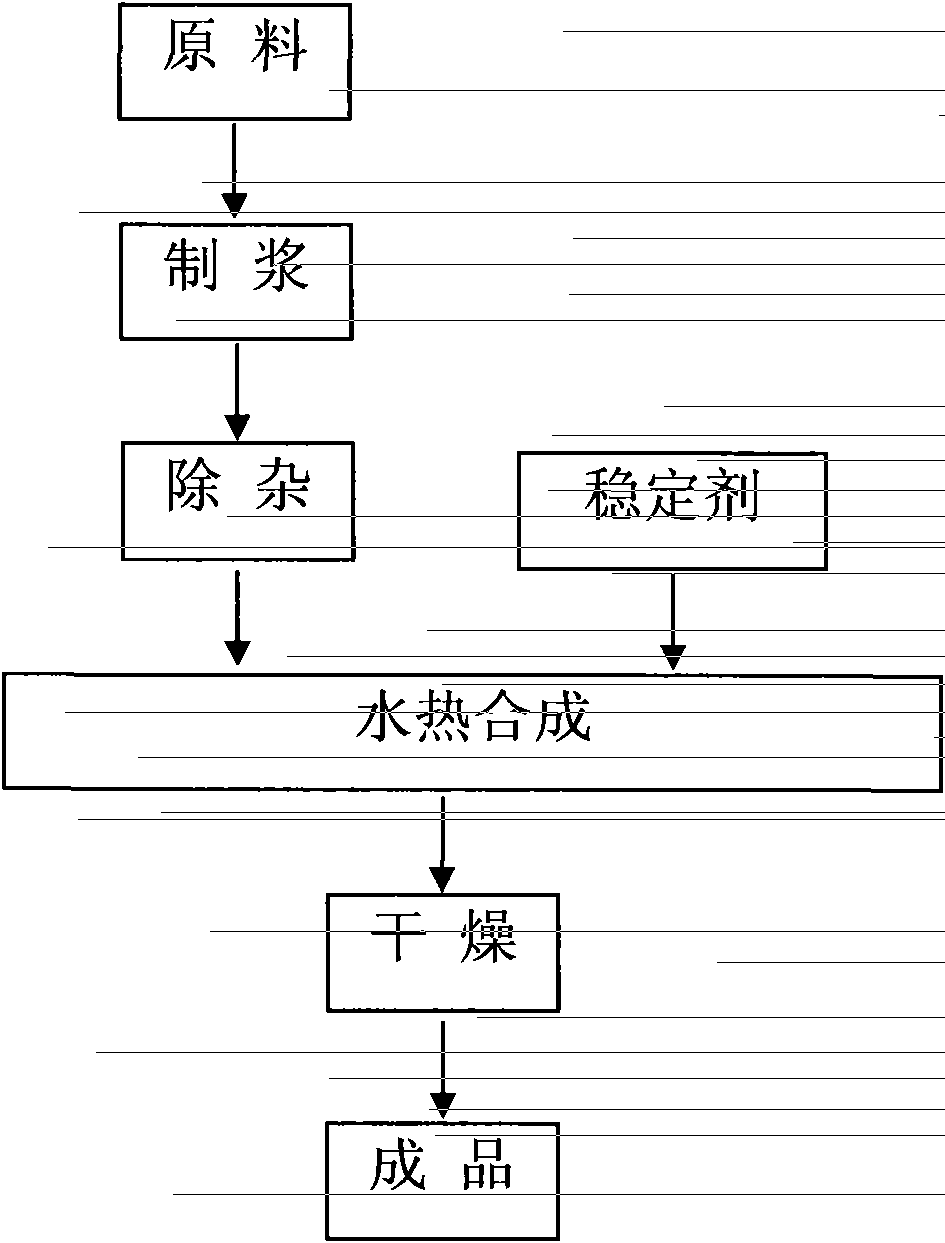

Method used

Image

Examples

Embodiment 1

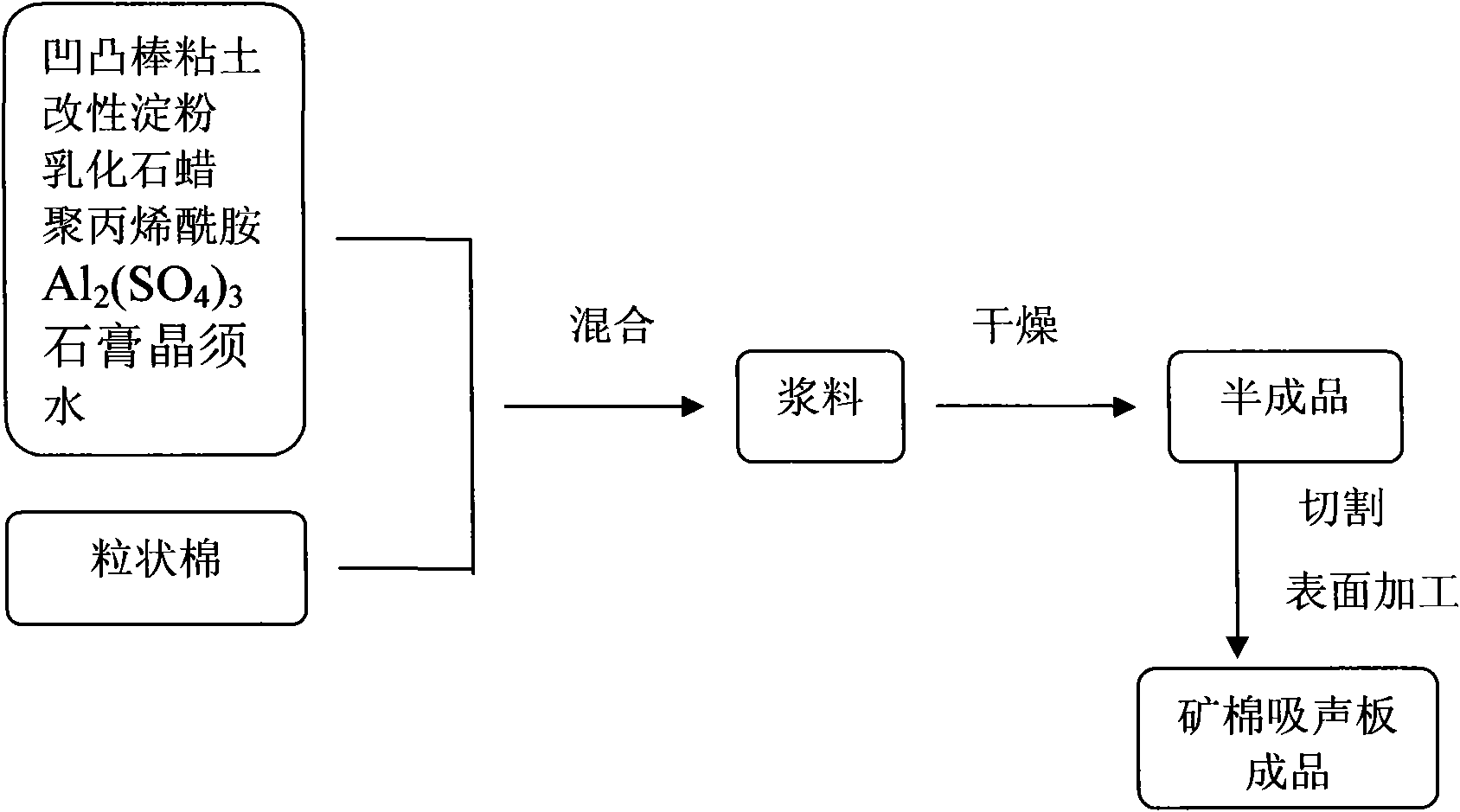

[0046] according to figure 2 The flowchart shown is for mineral wool board preparation.

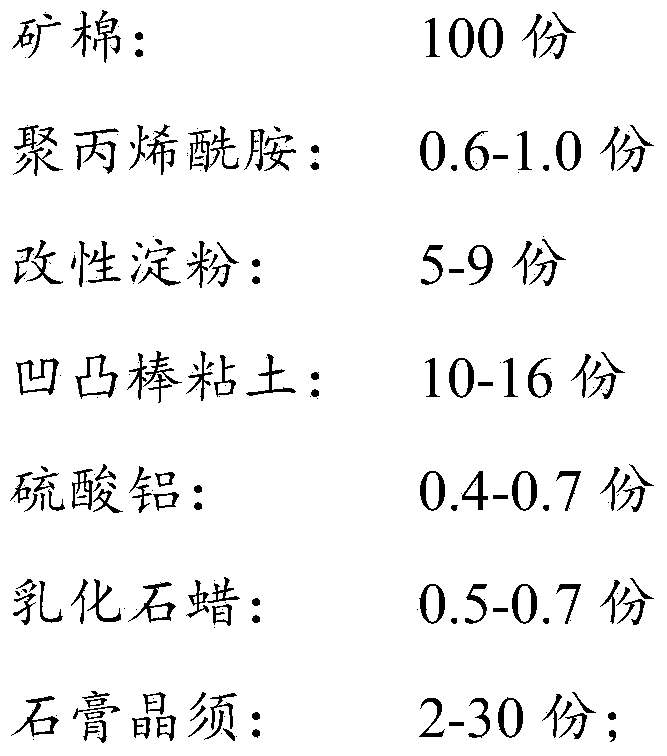

[0047] Step 1: Weigh 100 parts by weight of granular cotton, 10 parts by weight of attapulgite clay, 5 parts by weight of modified starch, 0.5 parts by weight of emulsified paraffin, 0.6 parts by weight of polyacrylamide, Al 2 (SO4) 3 0.4 parts by weight, 12 parts by weight of gypsum whiskers. After the above-mentioned raw materials are fully stirred in the batching mixer, they are output to the feeding machine.

[0048] Step 2: The above-mentioned mixed materials are wet-formed in a web forming machine, and cut into large slabs through a cutting machine with high-pressure water.

[0049] Step 3: Transport the above-mentioned slabs to a drying kiln through a distributor, and dry them at 230-285°C for about 2 hours.

[0050] Step 4: After the slabs are out of the kiln, they are cut into 600cm×600cm according to the specifications, and the surface finishing is carried out. The surface ...

Embodiment 2

[0054] In this example, weigh each component according to the following proportions: weigh 100 parts by weight of granular cotton, 14 parts by weight of attapulgite clay, 8 parts by weight of modified starch, 0.6 parts by weight of emulsified paraffin, and 0.9 parts by weight of polyacrylamide, Al 2 (SO 4 ) 3 0.6 parts by weight, 30 parts by weight of gypsum whiskers. The preparation process is the same as in Example 1, and a 12mm thick functional mineral wool board is obtained.

[0055] Tests show that the new high-strength mineral wool sound-absorbing panel complies with national standards, and compared with traditional mineral wool sound-absorbing panels, the physical and mechanical properties are significantly improved, and the bending failure load is increased by 30%.

Embodiment 3

[0057] In this example, the components were weighed according to the following proportions: 100 parts by weight of granular cotton, 16 parts by weight of attapulgite clay, 9 parts by weight of modified starch, 0.7 parts by weight of emulsified paraffin, 1.0 parts by weight of polyacrylamide, Al 2 (SO4) 3 0.7 parts by weight, 2 parts by weight of gypsum whiskers. The preparation process is the same as in Example 1, and a 12mm thick functional mineral wool board is obtained.

[0058] Tests show that the new high-strength mineral wool sound-absorbing panel complies with national standards, and compared with traditional mineral wool sound-absorbing panels, the physical and mechanical properties are significantly improved, and the bending failure load is increased by 10%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com