Environment-friendly starch glue for packaging paper and preparation method thereof

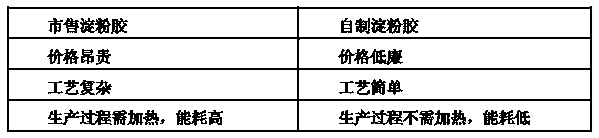

A technology of wrapping paper and starch glue, applied in the direction of biological packaging, sustainable packaging, starch-derived adhesives, etc., can solve the problems of high gelatinization temperature and high production cost, and achieve low cost, high practicability, and reduced The effect of industrial production energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

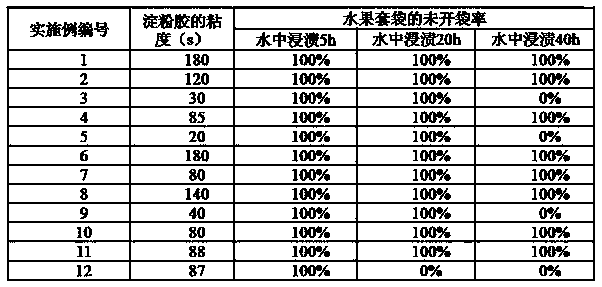

Examples

Embodiment 1

[0027] Dissolve 10g of cornstarch in 50g of water and stir evenly to obtain a starch solution; add 0.5g of sodium percarbonate to the resulting starch solution and react for 10 minutes to obtain an oxidized starch solution; dissolve 3g of sodium hydroxide in 50g of water to obtain sodium hydroxide solution; the obtained sodium hydroxide solution is added to the oxidized starch solution to react until the reaction system becomes clear (easy to operate on the machine), and the environmentally friendly starch glue for packaging paper bonding is obtained.

Embodiment 2

[0029] Dissolve 10g of cornstarch in 50g of water and stir evenly to obtain a starch solution; add 1.5g of sodium percarbonate to the resulting starch solution and react for 10 minutes to obtain an oxidized starch solution; dissolve 4g of sodium hydroxide in 50g of water to obtain sodium hydroxide solution; the obtained sodium hydroxide solution is added to the oxidized starch solution to react until the reaction system becomes clear (easy to operate on the machine), and the environmentally friendly starch glue for packaging paper bonding is obtained.

Embodiment 3

[0031] Dissolve 10g of cornstarch in 50g of water and stir evenly to obtain a starch solution; add 2.5g of sodium percarbonate to the resulting starch solution and react for 10 minutes to obtain an oxidized starch solution; dissolve 5g of sodium hydroxide in 50g of water to obtain sodium hydroxide solution; the obtained sodium hydroxide solution is added to the oxidized starch solution to react until the reaction system becomes clear (easy to operate on the machine), and the environmentally friendly starch glue for packaging paper bonding is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com