Prefabricated construction method for non-structural concrete component

A prefabricated assembly and concrete technology, applied in the direction of building components, building structures, building insulation materials, etc., can solve the problems of straightness control, formwork support difficulty, small angle, etc., to reduce on-site operations, improve economic and social Benefits, safe and convenient to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

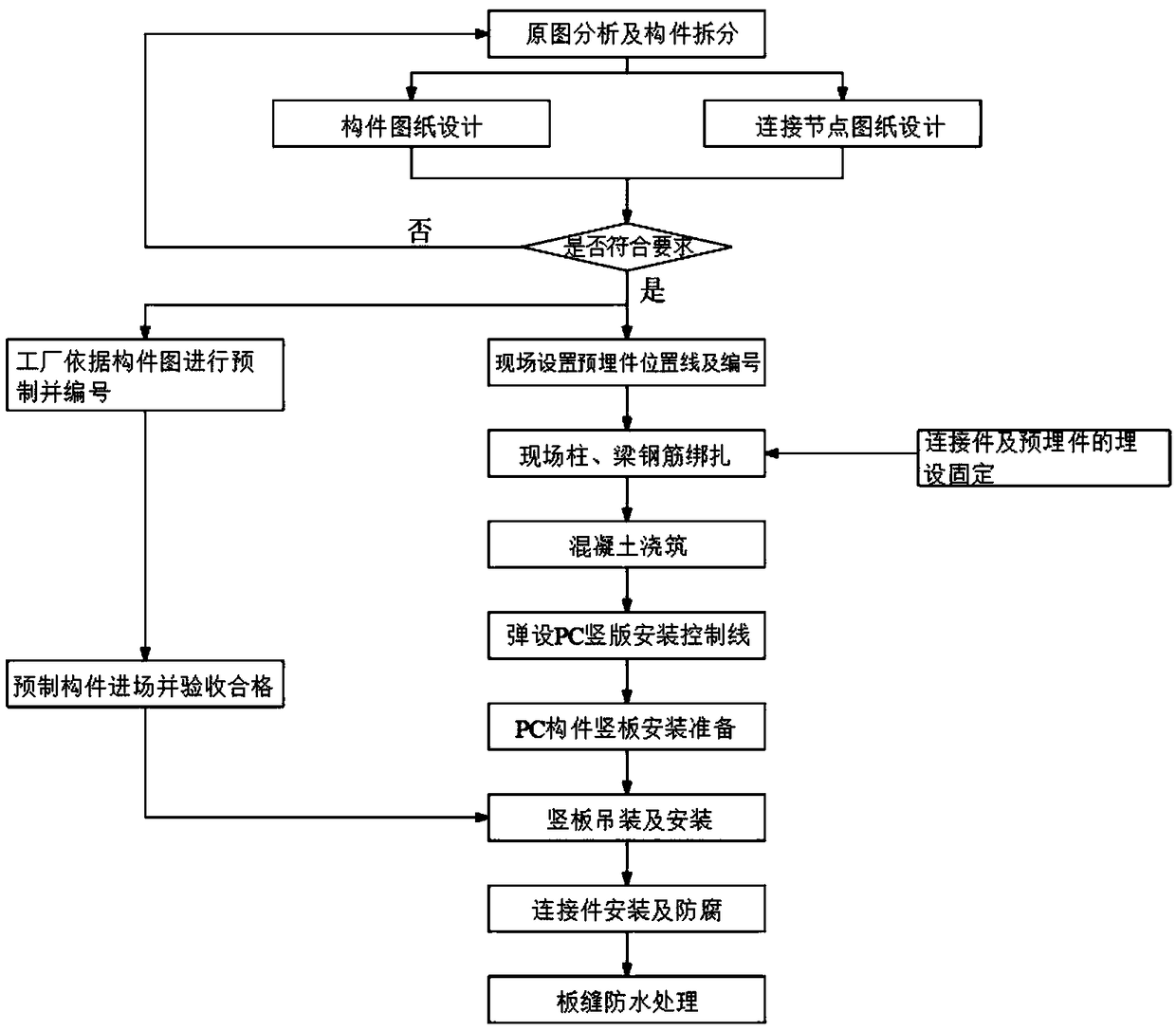

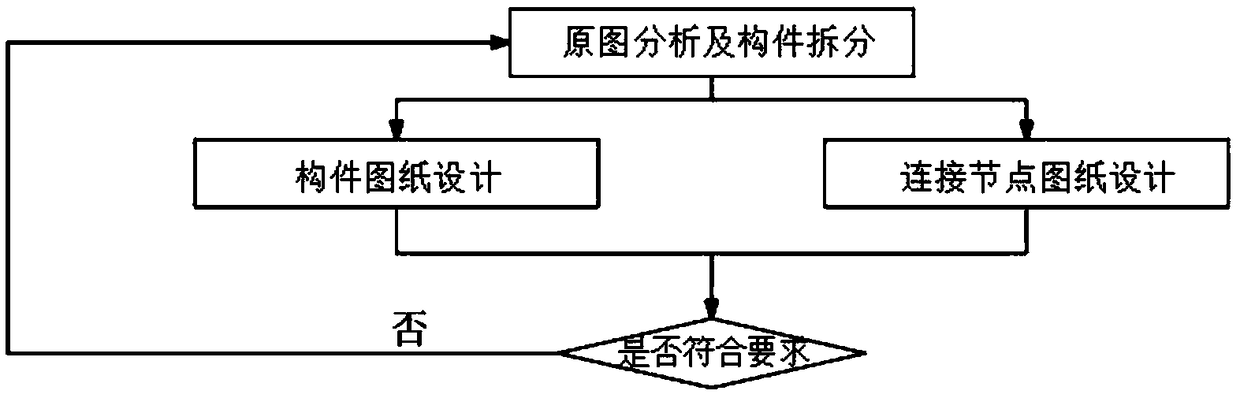

[0036] Example: such as figure 1 As shown, the present invention provides a technical solution, a prefabricated construction method for non-structural concrete components, comprising the following steps:

[0037] S1. Analyze the original drawing and split components;

[0038] S2. Design the component drawings and design the component connection node drawings;

[0039] S3. Check whether the designed drawings meet the requirements for on-site use, and if not, return to step S1;

[0040] S4. The factory performs prefabrication and numbering according to the component drawing;

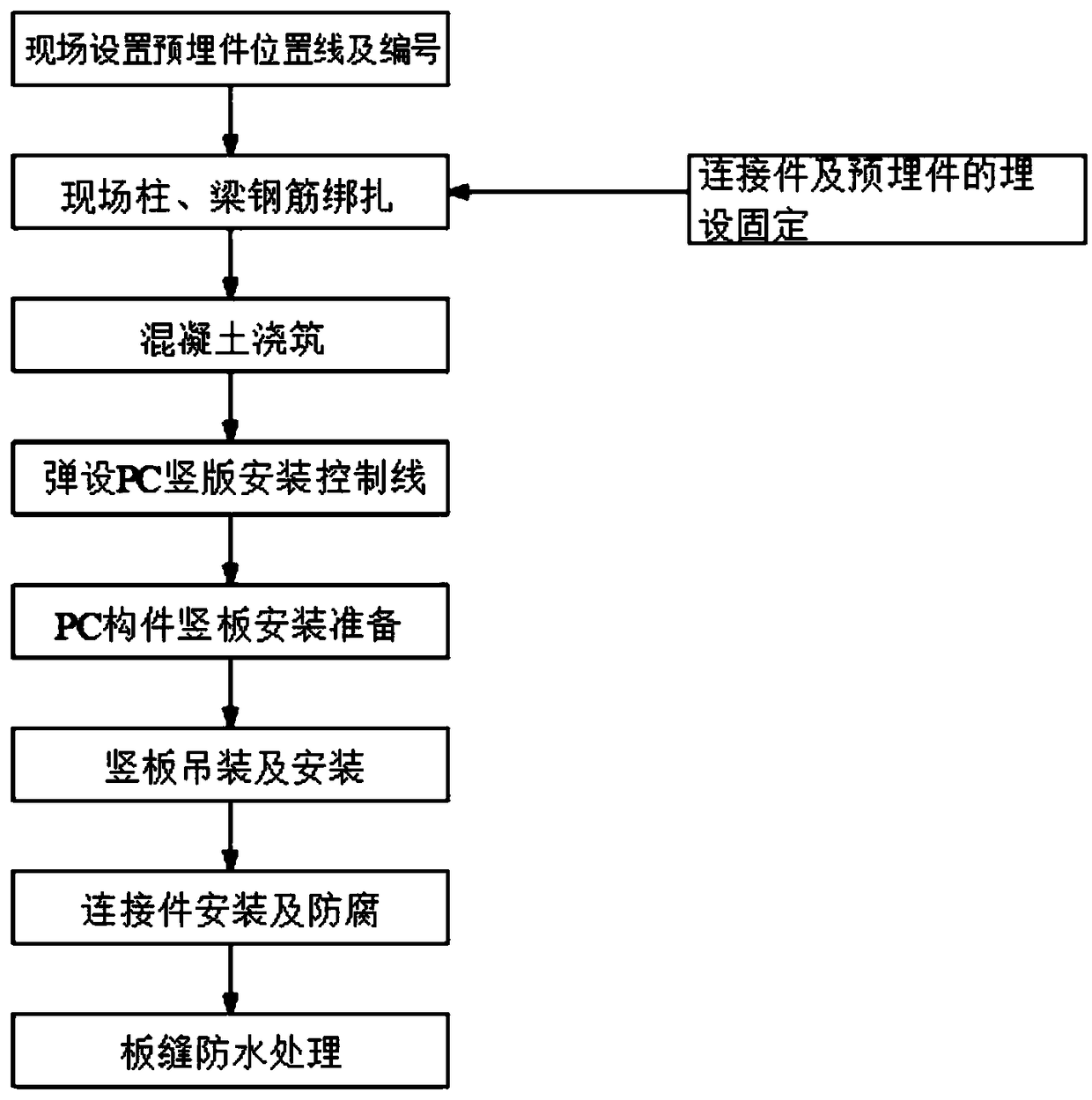

[0041] S5. Set the position line and number of the embedded parts on site;

[0042] S6, bury and fix the connectors and embedded parts, and bind the column and beam reinforcement on site;

[0043] S7, pouring by concrete;

[0044] S8. Install the control line by ejecting the PC vertical board;

[0045] S9, preparing for installation of the PC member vertical plate;

[0046] S10. Bring the prefabrica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com