Gas-sensitive film sensor of the graphene oxide and graphene composite structure acquired by CVD graphene through non-pollution transfer technology and method thereof

A graphene composite and thin-film sensor technology, applied in the field of sensing, to avoid being easily disturbed by environmental noise, improve adsorption characteristics, and improve gas sensitivity response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

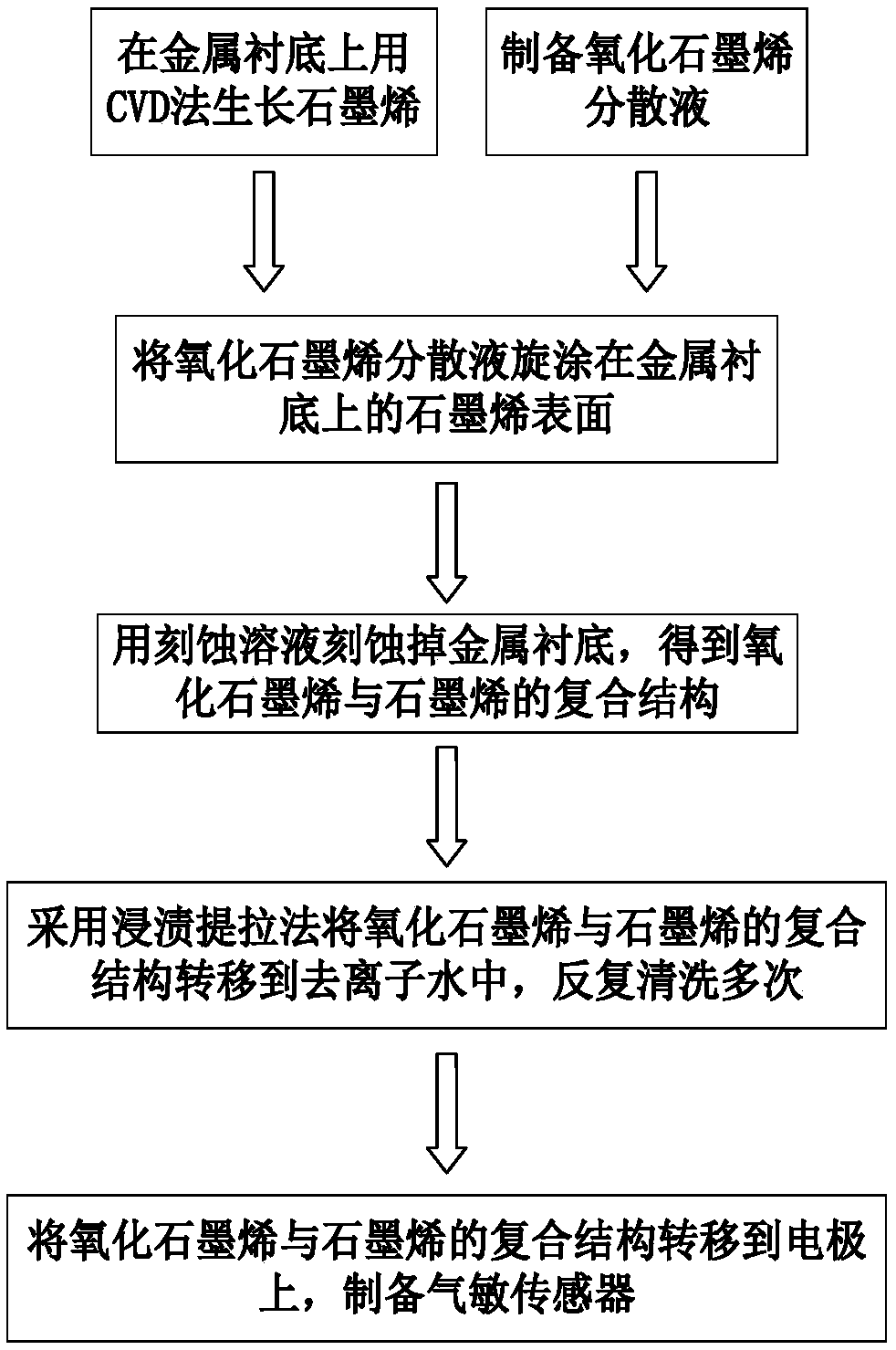

Method used

Image

Examples

preparation example Construction

[0039] 1) Preparation of graphene oxide dispersion

[0040] Take 5-50 mg of graphene oxide, put it into 40 ml of deionized water and shake it for 10-60 minutes, and then sonicate for 4-24 hours to obtain a uniformly dispersed graphene oxide dispersion.

[0041] 2) Transfer of graphene

[0042] 2.1) Spin-coated graphene oxide

[0043]The CVD graphene with metal substrate is placed on the homogenizer, get step 1) prepared graphene oxide dispersion liquid, drop on the graphene surface of CVD graphene, then let the CVD graphene with metal substrate with 100 -Rotate at a speed of 1000 rpm for 30-90 seconds. After completion, structure A is obtained. Remove structure A from the homogenizer, place it on a heating table, and bake it at 40-80°C for 1-30 minutes to remove Spin-coated graphene oxide and moisture in graphene make graphene oxide and graphene form a composite structure, and anneal the composite structure of graphene oxide and graphene, and then remove structure A. Using ...

Embodiment 1

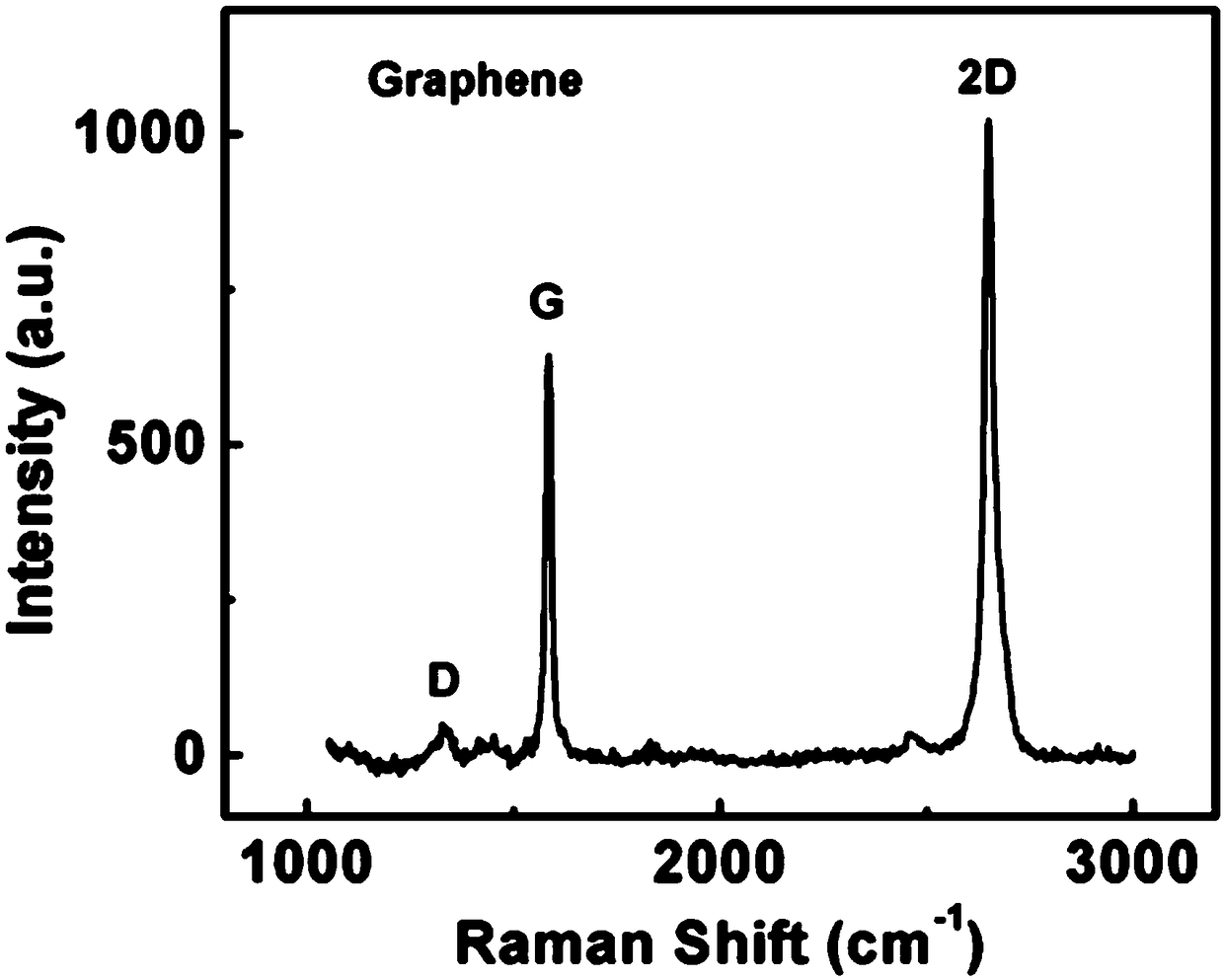

[0052] The pollution-free transfer process of CVD graphene of the present embodiment obtains the method for the gas-sensitive film sensor of graphene oxide and graphene composite structure, comprises the following steps:

[0053] 1) Preparation of graphene oxide dispersion

[0054] Take 24 mg of graphene oxide, put it into 40 ml of deionized water and shake it for 20 minutes, and then sonicate for 6 hours to obtain a uniformly dispersed graphene oxide dispersion.

[0055] 2) Transfer of graphene

[0056] 2.1) Spin-coated graphene oxide

[0057] The CVD graphene with copper foil substrate is placed on the glue homogenizer, 0.2mL of graphene oxide dispersion liquid prepared in step 1) is dropped on the graphene surface of CVD graphene, and then the CVD graphene with copper foil substrate is allowed to The graphene was rotated at a speed of 500 rpm for 45 seconds. After the completion, the structure A was obtained. The structure A was removed from the homogenizer, placed on a h...

Embodiment 2

[0074] The pollution-free transfer process of CVD graphene of the present embodiment obtains the method for the gas-sensitive film sensor of graphene oxide and graphene composite structure, comprises the following steps:

[0075] 1) Preparation of graphene oxide dispersion

[0076] Take 5 mg of graphene oxide, put it into 40 ml of deionized water and shake it for 10 minutes, and then sonicate for 4 hours to obtain a uniformly dispersed graphene oxide dispersion.

[0077] 2) Transfer of graphene

[0078] 2.1) Spin-coated graphene oxide

[0079] The CVD graphene with nickel substrate is placed on the homogenizer, get the graphene oxide dispersion liquid 0.2mL prepared in step 1), drop on the graphene surface of CVD graphene, then let the CVD graphene with nickel substrate Rotate at a speed of 100 rpm for 30 seconds. After completion, structure A is obtained. Remove structure A from the homogenizer, place it on a heating table, bake at 80°C for 1 minute, and then remove structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com