A kind of ethyl acetate gas sensor and preparation method thereof

A gas sensor, ethyl acetate technology, applied in instruments, scientific instruments, measuring devices, etc., can solve problems such as threatening life and property safety, easy to explode, etc., and achieve the effects of small size, low cost, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

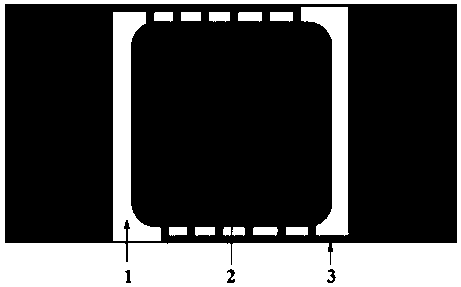

Image

Examples

Embodiment 1

[0045] First, use acetone and ethanol cotton balls to wipe the Al with Pd metal interdigitated electrodes with a width of 3mm and a length of 4mm prepared by screen printing technology. 2 o 3 The substrate is clean, and then the Al with Pd metal interdigitated electrodes 2 o 3 The substrate was placed in acetone, ethanol and deionized water in turn, ultrasonically cleaned for 5 minutes respectively, and finally dried at 100°C for later use.

[0046] Among them, the use of screen printing technology in Al 2 o 3 Prepare Pd metal finger electrodes on the substrate, according to the mass ratio of ink [Jiahua JX07500487]:Pd powder:diluent is 1:1:2, stir to make a paste; then inject the paste into the On the screen plate of the finger electrode pattern, scrape the paste under the conditions of an inclination angle of 30° and a pressure of 5 Newtons, print the electrode and dry it, and complete the preparation of the Pd metal finger electrode after UV curing. The width and elect...

Embodiment 2

[0053] First, use acetone and ethanol cotton balls to wipe the Al with a width of 3 mm and a length of 4 mm with Pd metal interdigitated electrodes prepared by screen printing technology. 2 o 3 The substrate is clean, and then the Al with Pd metal interdigitated electrodes 2 o 3 The substrate was placed in acetone, ethanol and deionized water in turn, ultrasonically cleaned for 5 minutes respectively, and finally dried at 100°C for later use.

[0054] Among them, screen printing technology is used to prepare pd metal interdigitated electrodes, according to the mass ratio of ink [Jiahua JX07500487]: pd powder: diluent is 1:1:2, stir and prepare a paste; then inject the paste On the screen plate with the interdigitated electrode pattern, scrape the paste at an inclination angle of 45° and a pressure of 10 N, print the electrode and dry it, and complete the preparation of the metal interdigitated electrode after UV curing. The width and electrode spacing of the interdigitated ...

Embodiment 3

[0061] First, use acetone and ethanol cotton balls to wipe the Al with a width of 3 mm and a length of 4 mm with Pd metal interdigitated electrodes prepared by screen printing technology. 2 o 3 The substrate is clean, and then the Al with Pd metal interdigitated electrodes 2 o 3 The substrate was placed in acetone, ethanol and deionized water in turn, ultrasonically cleaned for 5 minutes respectively, and finally dried at 100°C for later use.

[0062]Among them, screen printing technology is used to prepare pd metal interdigitated electrodes, according to the mass ratio of ink [Jiahua JX07500487]: pd powder: diluent is 1:1:2, stir and prepare a paste; then inject the paste On the screen plate with the interdigitated electrode pattern, scrape the paste at an inclination angle of 45° and a pressure of 10 N, print the electrode and dry it, and complete the preparation of the metal interdigitated electrode after UV curing. The width and electrode spacing of the interdigitated e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com