Heterogeneous gas-sensitive nano material based on cerium oxide particle modified copper oxide nanowire structure and preparation process and application thereof

A technology of copper oxide nanowires and nanomaterials, applied in nanotechnology for sensing, nanotechnology for materials and surface science, nanotechnology, etc., can solve problems such as damage to human health, corrosion, strong irritation, etc. , to achieve the effects of low cost, high preparation efficiency, and improved selectivity and consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

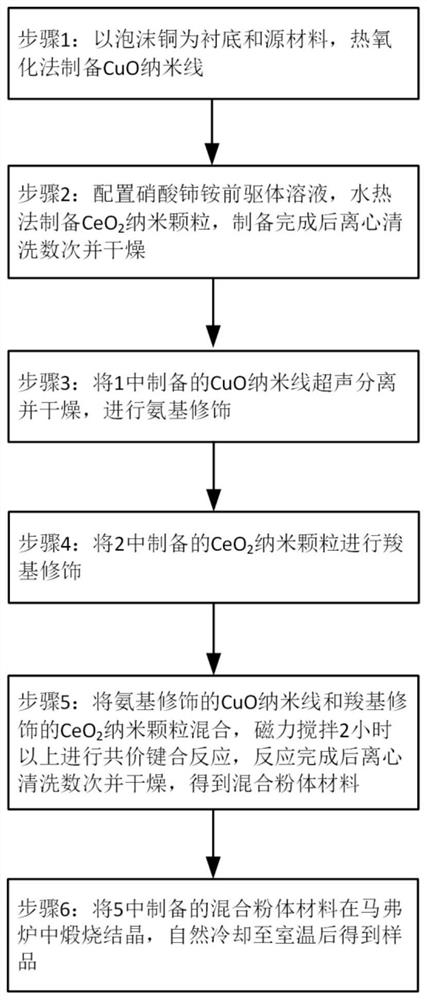

Method used

Image

Examples

Embodiment 1

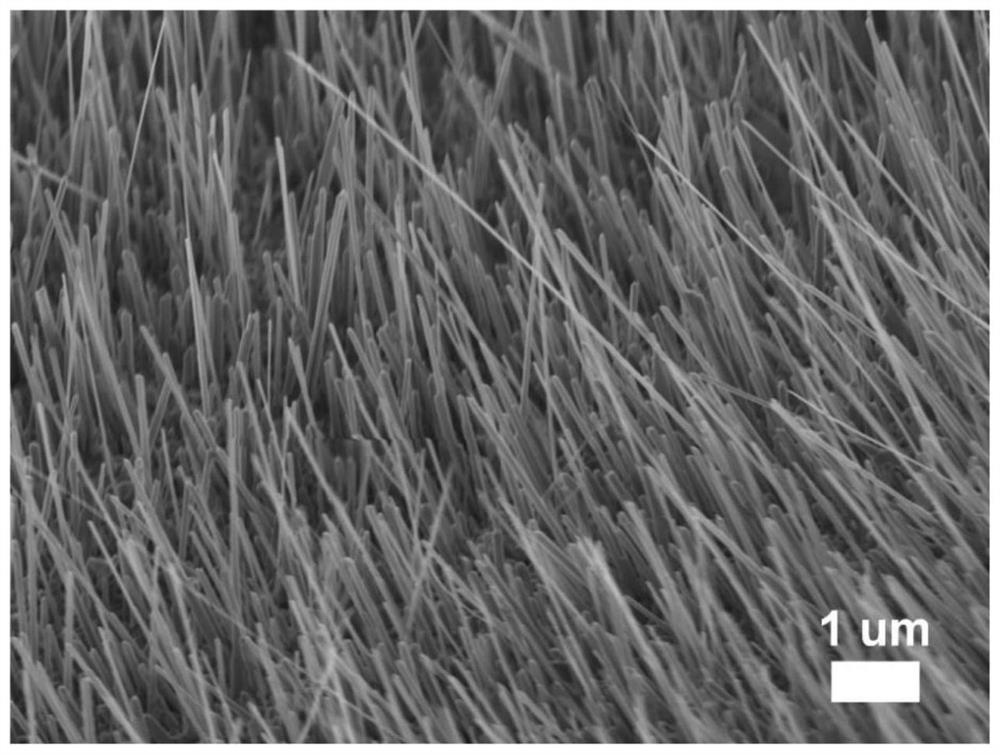

[0059] (1) The copper foam that was ultrasonically cleaned with anhydrous ethanol and deionized water for 10 min and dried as the substrate and source material was put into a tube furnace for thermal oxidation, the ventilation atmosphere was high-purity oxygen, and the growth temperature was 500 °C , the growth time is 12 hours, and CuO nanowires are obtained, and its SEM image is as follows figure 2 As shown, it can be seen that the average diameter of CuO nanowires is about 90 nm, and the average length is about 10 μm;

[0060] (2) Prepare cerium ammonium nitrate solution with a concentration of 0.2 mol / L as a precursor solution and pour it into a hydrothermal kettle for hydrothermal reaction. The growth temperature is 200 °C and the growth time is 5 hours. After the reaction is completed, centrifuge with absolute ethanol Washed several times and dried to obtain CeO 2 nanoparticles;

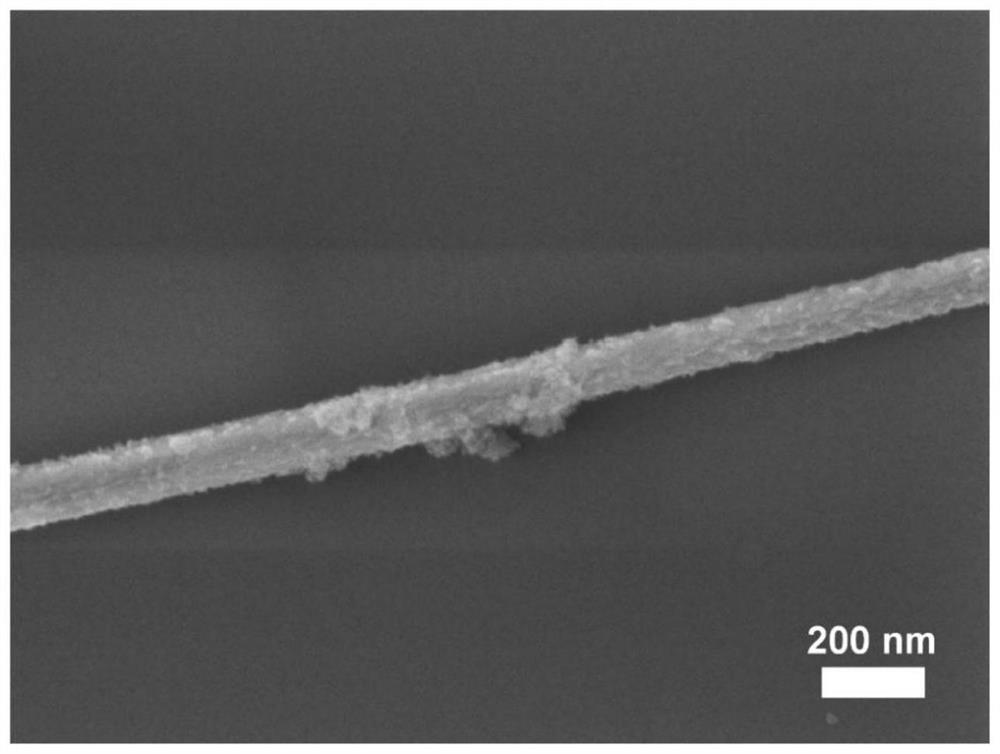

[0061] (3) Ultrasonically separate and dry the CuO nanowires prepared in step (1) from t...

Embodiment 2

[0075] Similar to Example 1, the difference is that the hydrothermal method grows CeO 2 The growth temperature of the nanoparticles was 240°C, and the growth time was 5 hours. The obtained single CeO 2The SEM characterization of the particle-modified CuO nanowire gas sensor device is shown in Figure 10 shown. The single CeO synthesized under this process condition 2 The particle-modified CuO nanowire gas sensor device was also tested for hydrogen sulfide gas sensing performance, and the results are as follows: Figure 11 As shown, although its response is higher than that of the single CeO in Example 1 2 The particle-modified CuO nanowire gas sensor device is slightly lower, but compared with a single pure CuO nanowire device, the improvement is still obvious.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| Average length | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com