Ethanol gas sensor based on Ga-doped beta-Fe2O3 nano octahedral sensitive material and preparation method of ethanol gas sensor

A beta-fe2o3, gas sensor technology, applied in the direction of analysis of materials, material resistance, material analysis through electromagnetic means, etc., can solve the problems of easy explosion, threat to life and property safety, etc., achieve small device size, improve gas sensitivity response , suitable for mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

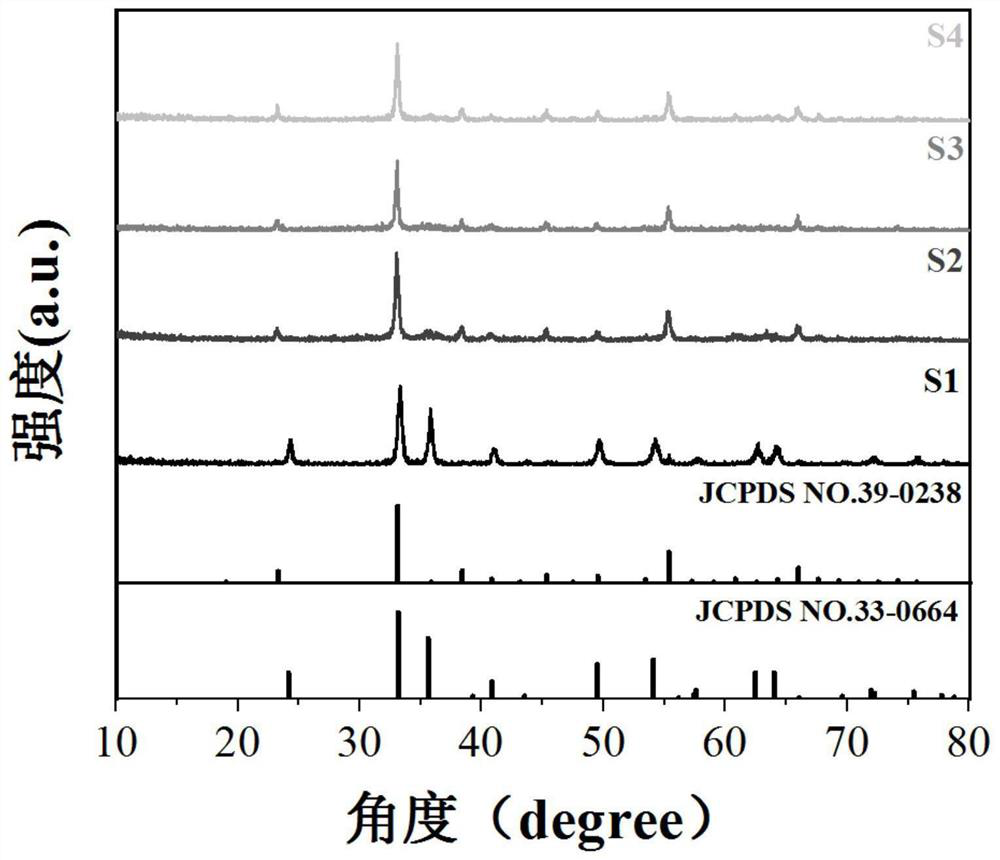

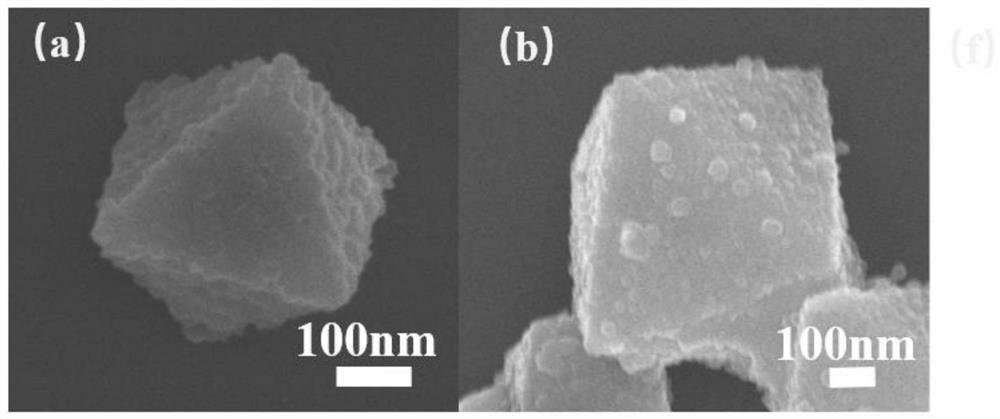

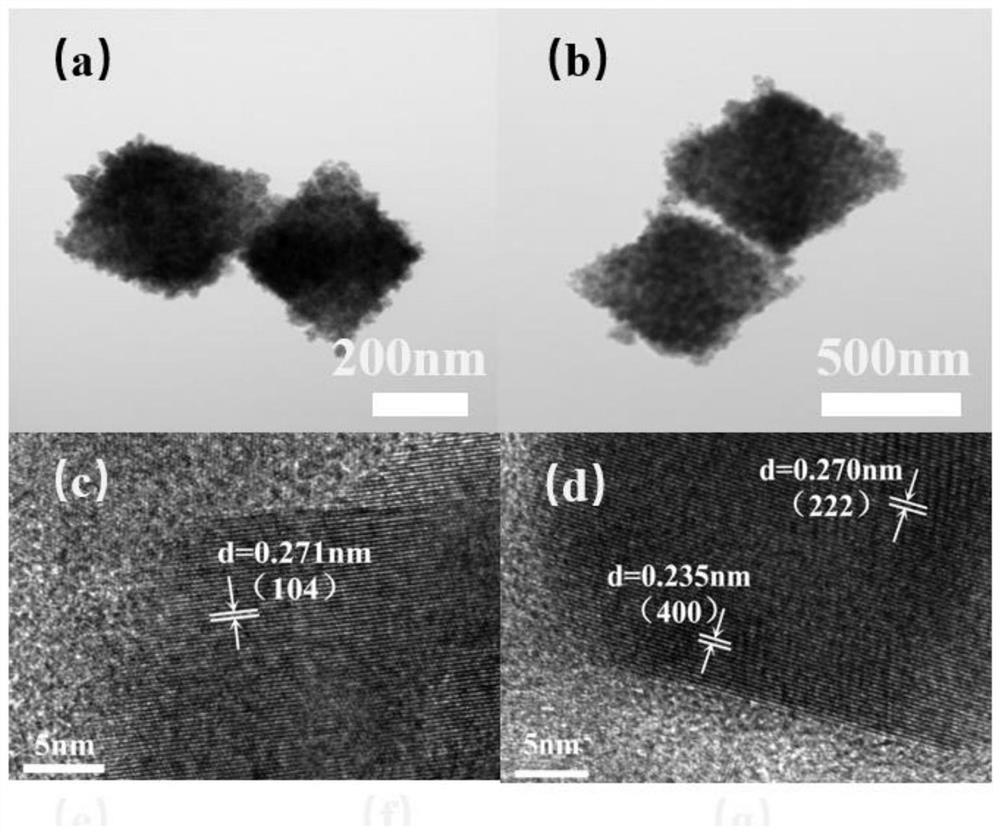

Embodiment 1~2

[0033] 1. Treatment of Pd metal interdigitated electrodes:

[0034] Wipe the Al with Pd metal interdigitated electrodes with acetone and ethanol cotton balls respectively 2 o 3 The substrate is clean, and then the Al with Pd metal interdigitated electrodes 2 o 3 The substrate was placed in acetone, ethanol and deionized water in turn, ultrasonically cleaned for 5 minutes, and finally dried at 100 °C;

[0035] The present invention uses screen printing technology on Al 2 o 3 Prepare Pd metal interdigitated electrodes on the substrate, the specific method is as follows: mix the ink [Jiahua JX07500487], Pd powder, and diluent at a mass ratio of 1:1:2, stir to make a paste; then pour the paste into On to the screen plate with the interdigitated electrode pattern, scrape the paste under the condition of 30 ° tilt angle and 5 Newton pressure, in Al 2 o 3 The interdigitated electrodes are printed on the substrate and dried, and the preparation of the Pd metal interdigitated el...

Embodiment 3

[0046] The treatment process of the Pd metal interdigitated electrodes is the same as that in Example 2.

[0047] 0.20g of terephthalic acid, 0.68g of ferric chloride hexahydrate and 0.052g of gallium nitrate were dissolved in 15mL of dimethylformamide (analytically pure), stirred for 2h; Reaction at 110°C for 20 hours; after cooling to room temperature, the product was centrifuged with ethanol and dried at 70°C for 24 hours; finally annealed at 400°C for 2 hours in air to obtain a Fe / Ga bimetallic organic framework Derived Ga-doped beta-Fe 2 o 3 nano-sensitive materials.

[0048] Ga-doped beta-Fe derived from Fe / Ga bimetallic organic frameworks 2 o 3 Preparation of nano-sensitive material gas sensor: the experimental process is the same as in Example 2, and the device prepared based on this material is marked as S3.

Embodiment 4

[0050] The preparation process of the Pd metal interdigitated electrode is the same as in Example 2.

[0051] 0.20g of terephthalic acid, 0.68g of ferric chloride hexahydrate and 0.078g of gallium nitrate were dissolved in 15mL of dimethylformamide (analytically pure), stirred for 2h; Reaction at 110°C for 20 hours; after cooling to room temperature, the product was centrifuged with ethanol and dried at 70°C for 24 hours; finally annealed at 400°C for 2 hours in air to obtain a Fe / Ga bimetallic organic framework Derived Ga-doped beta-Fe 2 o 3 nano-sensitive materials.

[0052] Ga-doped beta-Fe derived from Fe / Ga bimetallic organic frameworks 2 o 3 Preparation of nano-sensitive material gas sensor: the experimental process is the same as in Example 2, and the device prepared based on this material is marked as S4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com