Substrate for power modules

A power module and substrate technology, which is applied in the direction of circuit substrate materials, improvement of metal adhesion of insulating substrates, welding equipment, etc., can solve problems such as partial discharge characteristics and deterioration of withstand voltage characteristics, and achieve suppression of partial discharge characteristics and withstand voltage characteristics The effect of deterioration, suppression of partial discharge, and suppression of charge concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0103]

[0104] Hereinafter, the results of confirmation experiments conducted to confirm the effects of the present invention will be described.

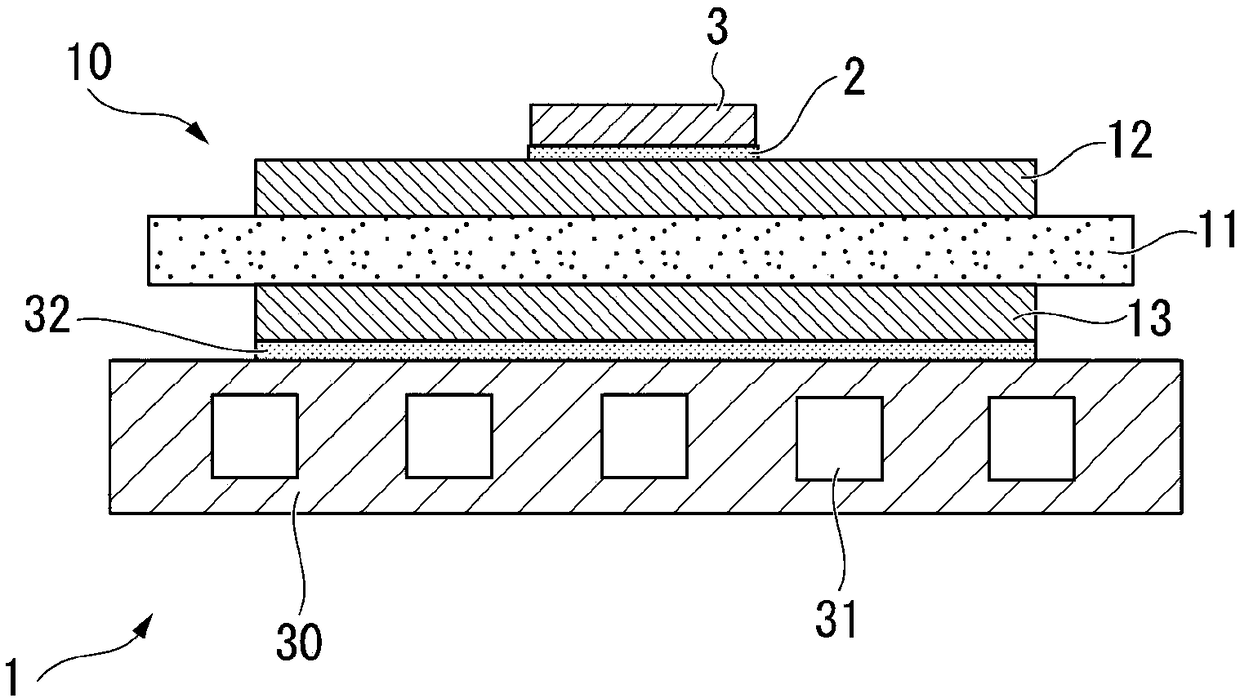

[0105] According to the procedures described in the above-mentioned embodiments, the ceramic substrates shown in Table 1 and Table 2 (50mm×60mm×thickness 0.635mm (AlN), 50mm×60mm×thickness 0.32mm (Si 3 N 4 ))) were bonded to one surface and the other surface of Cu plates (46 mm x 56 mm x thickness 0.3 mm) shown in Table 1 and Table 2 to form a circuit layer and a metal layer. As the Cu plate, oxygen-free copper ("OFC" in Table 1 and Table 2) or tough copper ("tough copper" in Table 1 and Table 2) was used. Cu-P-Sn based solder with a thickness of 25 μm was used.

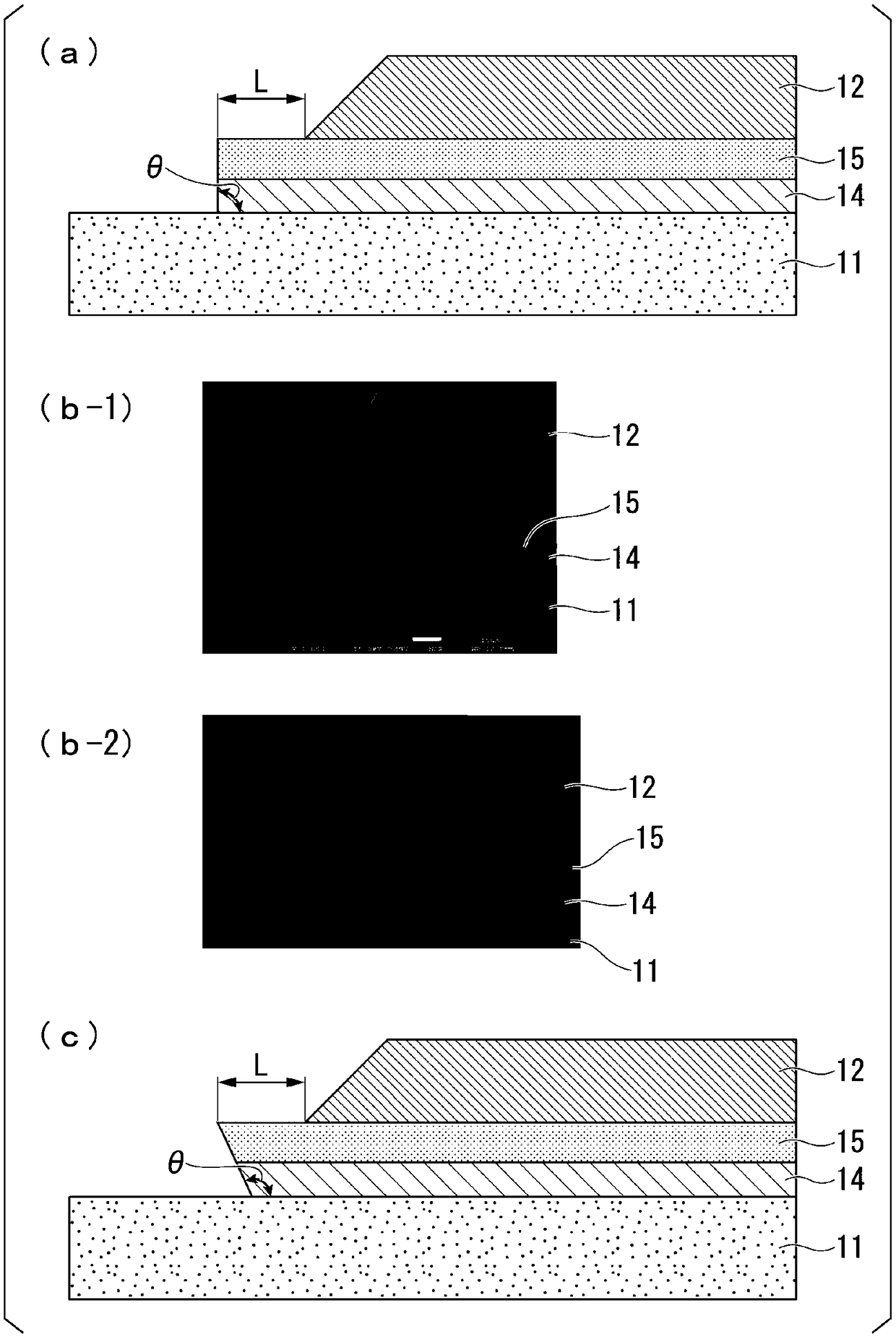

[0106] Then, the etching process described in the above-mentioned embodiment was performed on the circuit layer, thereby forming a circuit pattern with a distance between wirings of 500 μm. Specifically, in Cu etching process S31, spray etching was performed for 5 to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com